Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Stádel Károly Agricultural Machinery Factory and Foundry

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Literature, references | ||

| Related gallery |

| ADDRESS OF THE MEMORIAL SITE, ROUTE PLANNING |

Győr, Rákóczi Ferenc Street 32.

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

Street view:

| BRIEF OVERVIEW |

|

This was the location of Győr's first industrial plant, the agricultural machinery factory and foundry of Károly Stádel, founded in 1845. Until the end of World War II, the family-owned company played a decisive role in the region. Its quality products were worthy competitors to the English and American machines that were widespread in agriculture at that time. Stádel proved its competence with numerous newly developed equipment and patents, which were awarded at several national and international exhibitions. The company was hit twice by bombs during World War II, and a significant part of its buildings and machinery were destroyed. Due to their difficult financial situation, the family leased the company from 1950, which continued to operate under the name Kisalföldi Gépgyár. Following nationalization, the property became the first site of the Kisalföldi Gépgyárak és Öntödék Egyesülése Vállalat, which was formed by the merger of five iron and steel companies. The rationalization efforts of the 1950s aimed at partially merging the five sites that existed at that time and operating them more economically. The Kisalföld Machine Factory operated at this location until 1952. Today, only the residential building of the company owner family remains from the site. |

| DETAILED COMPANY HISTORY |

The history of the Stádel machine factory dates back to the early 1800s. It was then that József Stádel, a toolmaker and knifemaker, settled in Győr.

The excellent specialist quickly became a recognized and respected citizen of the city. His fortune grew nicely from his business, which he operated with several assistants. Károly's son was already acquainted with the craft at the age of 13. First in the family workshop, and then in Vienna, he learned all the branches of the iron trade from the basics to graduating from the Imperial and Royal Technical University. He gained his professional experience in various factories, such as the famous Viennese Tophan company.

After the death of József Stádel, he returned to Győr in 1844 and took over the management of the family business. He earned the title of master with his masterpiece submitted to the united locksmiths' guild, so he could now realize his ambitious plans in the company bearing his own name.

He purchased the property on Rákóczi Ferenc Street, suitable for a new location, in 1847 for 5,600 silver coins.

Successful introduction

The master toolmaker, who was already working with two assistants, made his first public appearance at the first Győr Industrial Exhibition in June 1846. At this event, initiated by Lajos Kossuth, Károly Stádel won a silver medal with his own designed pump – which could also be converted into a fire hose.

In the same year, the 3rd National Industrial Exhibition was held in Pest. Stádel also participated in this, and his rotary pump was awarded a bronze medal.

The great craftsmanship and successes he acquired during his one and a half years of operation encouraged him to implement new plans.

After the defeat of the War of Independence, he decided to significantly expand his workshop. His new premises were the previously purchased property at 34 Rákóczi Ferenc Street and the adjacent two-story corner house, purchased in 1853.

From workshop to factory

Stádel was also a valued supplier to the city council, and was regularly commissioned with several small and large jobs. The expansion of the customer base and the range of products prompted Stádel to obtain the title of factory for his well-known workshop.

Just like his father before him, he himself could count the Győr chapter estate among his regular customers, to which he delivered agricultural machinery. In possession of a letter of recommendation from the chapter's officer, he submitted an application to the Győr City Council in January 1862 to obtain the title of factory. Following the permission of the District Council dated April 24, 1862, it was deemed worthy of the title of "nationally patented factory".

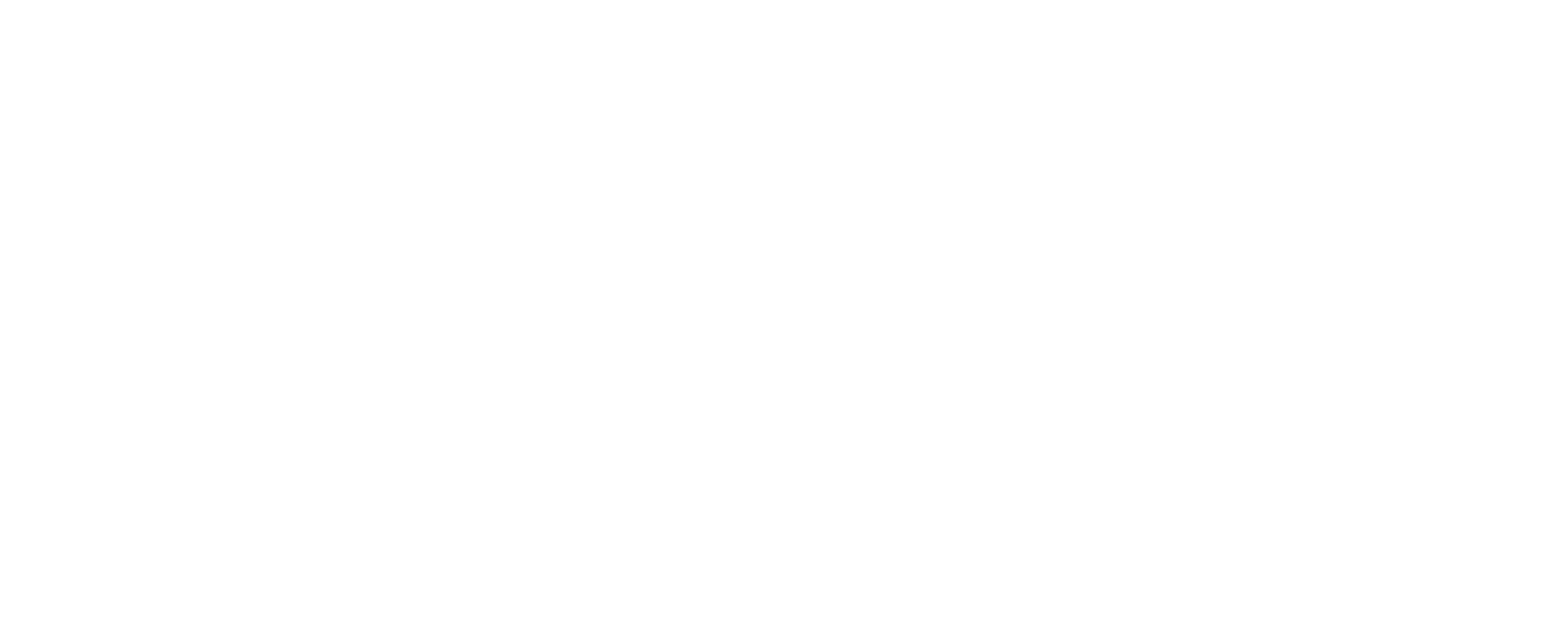

Surviving colorful advertising graphics from the Stádel factory

The first international competition

The Stádel factory achieved its first foreign success at the Vienna International Economic Exhibition in 1866. It received a state prize for its automobile, and a large bronze medal for its machine collection.

The next international recognition was the medal of merit he received for his corn crusher and threshing machine presented at the 1873 Vienna World Exhibition.

A new foundry is being built

Károly Stádel submitted his application to the city council in 1877, requesting the possibility of building a new foundry in the yard of his premises. The decision of the authority, which approved the application in just four days, gave the machine factory the opportunity to produce its own economical and competitive castings.

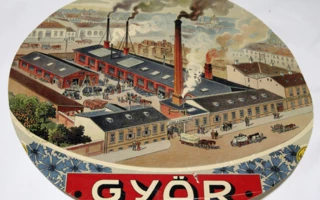

Károly Stadel announced the establishment of his foundry in the February 4, 1877 issue of the Győri Közlöny.

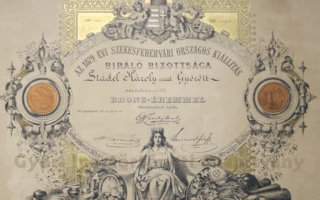

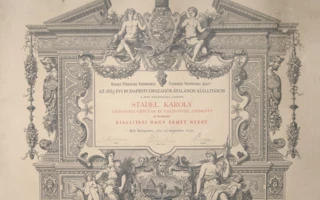

The recognition earned at the national exhibition held in Székesfehérvár in 1879

By the end of the 1880s, significant competitors, such as Kühne from Mosonmagyaróvár, had emerged in the machinery industry. With their more favorable prices, it was becoming increasingly difficult for the Stádel factory, which specialized in producing high-quality products, to compete.

An era ends

The death of Károly Stádel in 1887 also marked the end of a successful era in the company's life. The factory was inherited by his son Károly Stádel Jr., who – like his father before him – learned and acquired the basic professional skills in the family business. He was a student at the Karlsruhe Technical College between 1867 and 1871. He returned home with the professional knowledge and education appropriate to the time to take over the management of the company.

His successful activities are also proven by the large exhibition medal he won at the 1885 Budapest National General Exhibition.

The name is obligatory

With the early death of Károly Stádel Jr., the factory was inherited by his three siblings: Mrs. Károlyné Fügi, née Erzésbet Mária Stádal, János Stádel and Mrs. Ferencné Knopp, née Alojzia Antónia Stádel.

The company continued to operate under the name “Károly Stádel Orökösei Gépgyár és Vasöntéde”.

Stadel advertisement from the magazine Ladies and Gentlemen Győr Millennium Calendar (1898)

Under the management of János Stádel, the factory remains popular among customers who demand quality and reliability. Thanks to their regular developments, they traditionally perform well at international and domestic exhibitions. Among their new patents, their row-sowing machine called the “Győri Drill” manufactured from 1902 is worth mentioning.

From 1910, after buying out his brothers' share, the sole owner of the factory was János Stádel, a landowner originally from Zalatárnok. The company's successes, which produced stable profits, were put to an end by World War I. The decline continued after the war. The number of employees fell; in 1930, the factory employed 30 workers, but by 1933, only 5 employees were working. The company supported itself by machine repairs and contract castings.

The last Stádel heir

Upon János Stádel's death in 1933, his son, Károly Richard Stádel , took over the reins. He was also a professional, having earned his mechanical engineering degree from the Budapest University of Technology in 1914.

In the 1930s, the main activity of the machine factory was casting. The company was a permanent supplier to the Győr City Engineering Office. Walking around the city, we can still find a large number of manhole covers and gullies cast by Stádel.

The company was unable to take advantage of the economic boom that was felt in the late 1930s. Károly Stádel – rejecting the opportunities offered by bank loans – relied solely on his own strength, so the enterprise slowly shrank into a small-scale industrial enterprise.

The number of workers decreased to 14, which continued to decrease during World War II. Work was limited to casting and repairs. The final destruction was caused by two bomb hits on the company during the bombing of Győr on April 13, 1944, and the lack of machinery and equipment destroyed in the subsequent ground battles.

The years before nationalization

Károly Stádel was unable to rebuild the factory from its ruins with his own resources. While maintaining his ownership, he was forced to lease the company to locksmith Gyula Knapp and his son, and mechanical technician Antal Németh. From that time on, the company was registered under the name Kisalföldi Gépgyár. The company, which mainly undertook repair tasks, initially fulfilled orders with 16, and later with 45–50 people.

Antal Németh did not prove to be a decent entrepreneur. In collusion with the warehouseman of the wagon factory, he smuggled valuable steel products out of the factory instead of scrap iron. The fraud was exposed in March 1948, and the speculator, who also sabotaged the Stádel family's rent, was sentenced to 14 years in prison.

The ministry then appointed a temporary manager to head the factory. The ownership of the company remained in the hands of Károly Stádel until nationalization.

Association of Kisalföld Machine Factories and Foundries

The temporary state of affairs was ended by a decree of the National Economic Council in March 1950. At that time, the Kisalföldi Gépgyárak és Tödék Egyesülés (Kisalföldi Machine Factories and Foundries Association) was formed by merging five – and then two more – small factories.

The main scope of activity of the new state-owned company was the manufacture and assembly of machinery, bridges, iron structures, cranes, transport equipment, as well as iron and metal casting.

The production at several sites and the diversified scope of activities raised many problems. A significant change in the life of the company was brought about by the decision of the Ministry of Mechanical Industry to terminate the merger. In 1951, the Kisalföldi Machine Factory and Foundry was established.

The machine factory's activities shifted increasingly towards the machine manufacturing sector instead of consumer goods.

Facing agriculture!

Thanks to the developments implemented according to the slogan of the announced national program, the company, which already employed 285 people in 1954, developed from a small factory into a factory capable of producing large series again. The small agricultural machinery production program did not prove to be successful in the long term, so the Kisalföldi Machine Factory and Foundry left the domestic market in 1955 and began to produce primarily slaughterhouse and meat industry machinery for export to Bulgaria in 1955, and then to Soviet export in larger volumes from 1959.

What did the Kisalföld Machine Factory and Foundry produce in the 1950s ?

We can read about this in the January 20, 1956 issue of the Győr-Sopron County Newspaper:

“… The Győr Kisalföldi Machine Factory has abundantly supplied the domestic market with corn grinders and beet cutters in the past. This year, they are primarily producing machines for the food industry that had to be imported from abroad. They have already started manufacturing wafer baking machines. The first one will be delivered in January. So far, they have received orders for 18 pieces. These modern machines facilitate the export-oriented production of the Biscuit and Waffle Factory. About ten prototypes are being produced for the meat industry during the year. These include the pig elevator, beef splitting saw, ham curing equipment, searing drum, washing drum, scalding drum and pork skin remover. The prototype of the head splitter was completed at the end of last year, and it was successfully tested at the Budapest slaughterhouse. Its serial production will begin in February.”

Developments, new location

Based on the decision of the Ministry of Metallurgy and Mechanical Industry in 1960, the Kisalföld Machine Factory and Foundry was given the Győr airport site of the Budapest screw factory for further development. The relocation, which was implemented in several stages, began in March 1961 and, after overcoming numerous difficulties, was completed by December 1962.

A significant step in the company's development was the establishment of a prototype plant in 1962. This enabled the company to ensure its international competitiveness and the ever-growing demand for its products.

Steam locomotive in production?

In 1961, the new screw factory site lacked many conditions for production and ensuring adequate working conditions for the workers. For example, the heating of the hall had not been solved. The problem, which became increasingly difficult as winter set in, was finally solved with an unusual idea. The factory rented a scrapped steam locomotive from MÁV, which, standing on the company's own industrial track, heated the workplaces with steam produced in its boiler.

In a new relationship

According to the decision of the Ministry of Metallurgy and Mechanical Industry in 1963, the Hungarian food industry factories were merged under the name of Food Equipment and Machine Manufacturing Company from 1964. The Kisalföld Machine Factory, which had previously separated from its foundry, was also incorporated into this large company.

The merger did not live up to the hopes attached to it, and in many cases made the production of products made in a completely new division of labor uneconomical.

Developments slowed down, so by the 1960s the technical parameters of the machines manufactured by the company were increasingly lagging behind even similar equipment from competitors from the CMEA countries.

The new economic mechanism

The new economic mechanism announced in 1968 aimed to reduce centralization and transfer much greater decision-making power and responsibility to local leaders.

The on-site assembly and warranty repairs of machines and equipment supplied by the Kisalföldi Machine Factory were carried out by the company's external assembly group, which was established in 1968. This department played a decisive role not only in Hungary but also abroad, even in the assembly and commissioning of entire cutting lines.

In a monopoly position

At the meeting of the Executive Committee of the CEEC countries in Budapest, it was decided that Hungary would be the base for the production of slaughterhouse, fruit, vegetable and canning machinery. The Kisalföld Machine Factory and Foundry fulfilled this no small task.

The machine factory later developed into a specialized manufacturer of slaughterhouse equipment. The Győr factory met the slaughterhouse needs not only of Hungary and the CEEC countries, but also of many capitalist countries.

It won't go any further...

The company was severely affected by the narrowing of its customer base. The biggest loss was the 60 million decrease in Soviet exports between 1968 and 1978. The Food Industry Equipment and Machine Manufacturing Company was unable to compensate for this with all other markets.

Another transformation and profile change

According to the decision of the Council of Ministers, the Food Industry Equipment and Machinery Manufacturing Company was taken over by the United Incandescent Lamp and Electricity Co. (EIVRT) from 1973. The transfer also partially changed the profile of the factory, as in addition to food industry machinery, the Győr factory unit began to manufacture more and more vacuum technology machines and equipment.

In 1975, EIVRT's second largest activity was mechanical engineering. This mainly involved the production of lamp and glass-working machines. During the production of complete production lines, many so-called turnkey factories were built in developing countries and the Soviet Union.

The majority of the machines manufactured at the Győr Machine Factory were vacuum technology products, more than four-fifths of which were exported to the CMEA countries. The exported products included vibrating feeders, packaging, lamp inspection, fluorescent lamp coating and glass processing machines. The electrical and electronic control units for the machines sold in the CMEA countries were manufactured from components originating from the Soviet Union. The majority of the equipment sold on convertible markets was not intended for vacuum technology purposes, but had other purposes, such as sheet metal working or punching presses.

The company was transformed in 1982. The previous organization did not allow for quick and flexible adaptation to changes in the world market, it was over-organized and bureaucratized. The company had 11 Hungarian and 2 foreign production plants. The foreign factories operated in the USA and Austria. These also formed the sales base of Tungsram Rt. there. The Austrian plant also carried out significant exports, primarily to Western Europe. Of the Hungarian factories, 4 were engaged in light source production and assembly, and two were specifically engaged in the production of light source components. Mechanical production was concentrated in two production sites, and electronics in three.

Tungsram Rt.'s market share attracted the interest of the American General Electric as early as the mid-1980s. GE became active in 1989 and acquired majority ownership of Tungsram following the first financial transaction that became an investment.

The last chapter

The fate of the Tungsram factory, which is now associated with the former Stádel Machine Factory only in the memories of the people of Győr, was sealed in 2008. The management of the American-owned company decided to close the Győr factory, citing the dramatically decreasing demand for traditional light bulbs in Europe. Despite all kinds of protests from the workers, the company closed its doors for good.

| LITERATURE |

Related gallery

Back to the previous page!