Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Richards Richard Cloth Factory

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Related gallery |

| MEMORIAL SITE ADDRESS, ROUTE PLANNING |

Győr, Tihanyi Árpád Street 23.

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

Street view:

| BRIEF OVERVIEW |

|

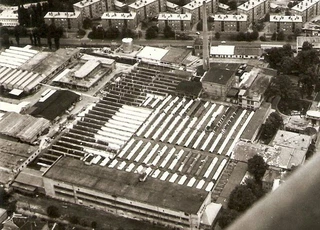

Aerial view around 1978 Richard Dunaréti Richards started his cloth-weaving factory on January 2, 1908, with 36 workers. He had the machines brought from Brno and England, and received a non-refundable grant of 200,000 crowns from the state and the city for the establishment of the factory in Győr. The factory primarily produced coat fabric, the largest customer of which was the state. A worsted mill was established on the company's premises in 1940. The factory was spared the war bombings. The cloth factory was nationalized in the spring of 1949, and shortly thereafter the Győr Wool Spinning- Weaving- Dyeing and Finishing Factory were attached to the factory. From then on, their name was Győr Wool Spinning and Weaving Factory. The new company name did not achieve great market success, and in 1957 the well-known Richards name was taken back. In the 1960s and 1970s, with the establishment of rural sites and mergers (Soproni Fésősfonó), the production vertical of the central plant became complete. Between 1968 and 1972, an investment of nearly 350 million HUF was made, as a result of which capital exports increased. From the mid-1980s, the profitability indicators of the business began to slowly but surely deteriorate. During the bankruptcy proceedings that began in early 1992, it was not possible to reach an agreement with the creditors, so the liquidation of the factory began in the fall of 1992. Production and trading continued for a few years in small limited companies that mushroomed on the ruins of the factory, albeit in a smaller volume than in previous years. A restaurant was set up in the factory building and observation tower on the factory grounds. The workers' quarters on the factory grounds were converted into a hotel. |

||

| DETAILED COMPANY HISTORY |

Richards of Dunaréti, as the company manager and then co-owner of the Back Hermann roller mill, established a weaving workshop on the mill site as early as 1905, where three weavers and a foreman began working on eight machines. This training workshop was also destroyed during the 1907 Back mill fire, but by then the foundations of the new factory buildings had already been laid on the ten thousand square meter area. Richards received a 15-year tax and paving duty exemption from the city for the establishment of the factory in Győr.

The cloth-weaving factory, which was opened on January 2, 1908, with 36 workers and 35 looms, had machinery brought from Brno and England. Born in Brno in 1867, Richards (originally named Max Kohn) married his maternal uncle's daughter, Karolina Back, and thus came into contact with the Back family. He inherited a large fortune from Hermann Back, the owner of the largest mill in Transdanubia, which made it easier to start the business. The factory primarily produced coat fabric, the largest customer of which was the state. The number of employees later increased to 50 people, and a fifty-horsepower semi-stable locomotive provided the driving force for the machines, which were considered modern at the time. In 1909, the finishing (fabric preparation) and dyeing house were built, so only the yarn was imported from abroad. From 1917, yarn was also produced locally. In 1918, the Kammer brothers, Hugó and Szigfrid, took over part of the shares, and gradually developed the Győr plant into a fully vertical plant producing world-class products.

Textil-Ipar, March 31, 1932, No. 6, p. 4.

The Kammer concern's exhibition at the textile exhibition of the Budapest International Fair in 1933.

As revealed by press reports, the Richards products on display were the following: women's and men's pure wool fabrics (Floconé), kasha trouser fabrics, Arcas d'ivior tennis trouser fabrics, tuxedo and tailcoat fabrics.

Textil-Ipar, 15 May 1933, No. 9, p. 6.

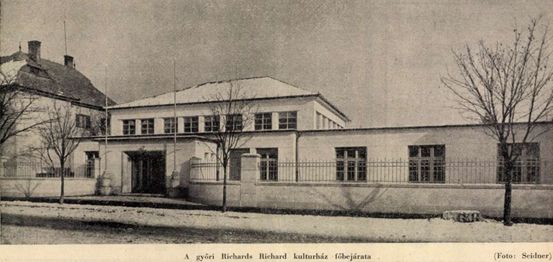

The Richards Cultural Center was inaugurated. Textil-Ipar, December 31, 1940, No. 26, p. 15.

In 1940, the Kammer Brothers established a worsted spinning mill in the city under the name Győri Fésősfonoda Rt. The two independent companies operated under joint management and administration.

During the operation of the concern, it also set an example with numerous worker welfare measures.

Textil-Ipar, May 5, 1941, No. 9, p. 12.

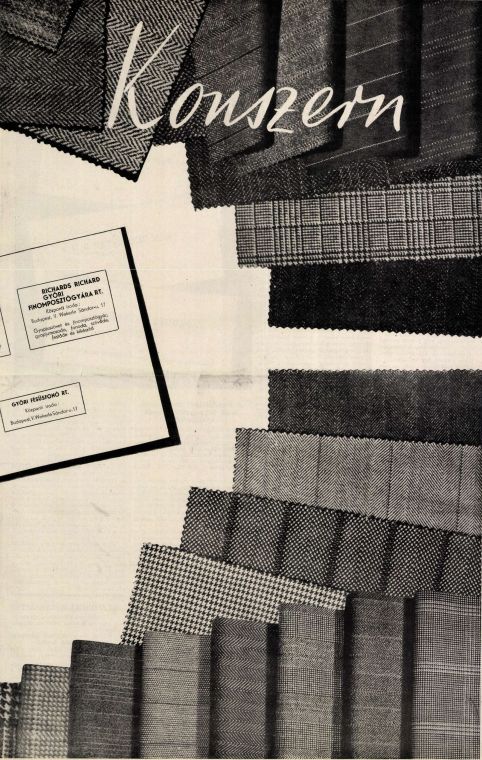

A wide range of quality fabrics were produced in the Győr factory in the early 1940s.

Advertising page in Textil-Ipar, issue 26, December 29, 1941

The factory, located in a residential area relatively far from strategic targets, survived the war bombings with minor damage. In 1945, after the war ended, work began in the factory within a few days. The machines and raw materials that had been evacuated to the countryside were brought back, and the wool and cotton were provided by the Russian army, so that the first fabric called Donsport could be produced. The poor working conditions are typical of the fact that the three hundred workers worked in an unheated building during the winter of 1945, and the weavers warmed their stiff fingers with light bulbs.

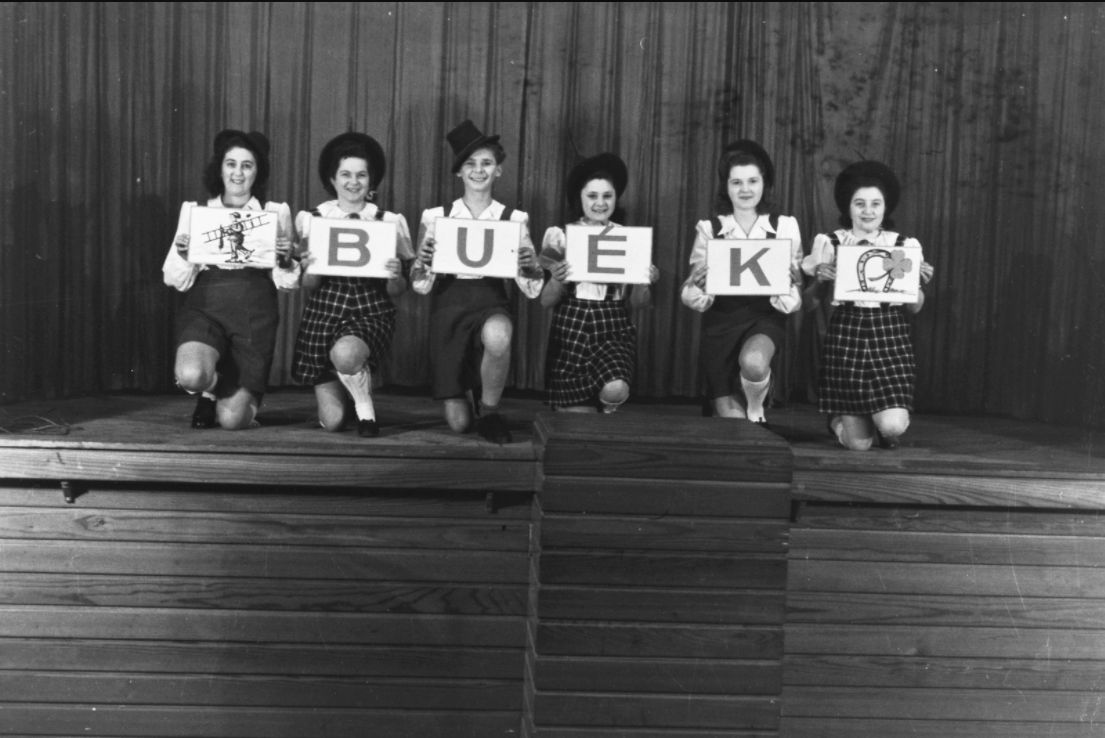

New Year's Eve show in the factory's cultural hall. Recording by Tamás Konok, 1948.

Source: fortepan/Tamás Konok, 1948.

The company became state-owned on March 26, 1948, and the two former factories were merged on March 11, 1949, under the name Richards Gyapjúfonó és Szövő NV. In that year, a workforce of 1,176 produced 1,200,000 square meters of fabric. In 1951, after the state purchased the Győri Gyapjúfonó-, Szövő-, Festő- és Kiskěstígyár Rt. from the French company Thibergien, it was attached to the Richards factory, from which point the company's new name became Győri Gyapjúfonó és Szövőgyár. This period is also referred to as the loden era, as men and partly women also wore loden coats. Loden fabric was produced in the Győr factory.

Lödenkabátok from 1960

Győr. Flower Market, formerly Egység tér, row of pavilions. 1960. Photographed by Tamás Konok.

Source: fortepan/Tamás Konok id.

The new company name did not achieve great market success, and Western salespeople were looking for the brand that had been known for half a century. From 1952 to 1954 and from 1957 to 1982, the factory director was Imre Ligeti, who had trained as a textile chemist in Brno. It was on his initiative that the well-known first name Richards was taken back in 1957.

Hungarian Film News 18. May 1967

Source: https://filmhiradokonline.hu/watch.php?id=19105

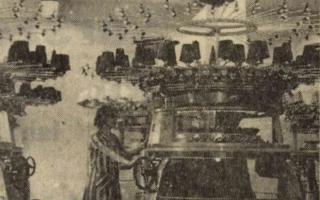

At this time, the use of synthetic fiber materials began. 45 percent wool and 55 percent polyacrylonitrile fabrics were produced for outerwear. The raw material of winter coat fabrics was made of half and half wool and camel hair.

In the 1960s and 1970s, with the establishment of rural sites (Kapuvár, Csorna, Öttevény, Lovászpatona) and mergers (Sopron Combing Mill), the production vertical of the central plant became complete.

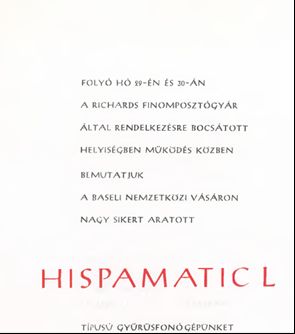

Invitation to a machine demonstration at the Richards Fine Mail Factory. 1968.

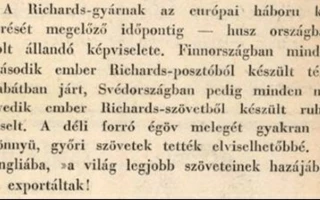

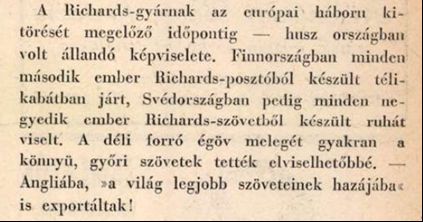

The largest investment in the factory's history took place between 1968 and 1972, when the nearly 350 million HUF development made technological processes simpler and more modern, reduced scrap, and improved quality, which was reflected in the increase in capital exports. In 1972, one-fifth of the products were exported, and in addition to democratic countries, they were also shipped to England, France, Kenya, Kuwait, and Libya.

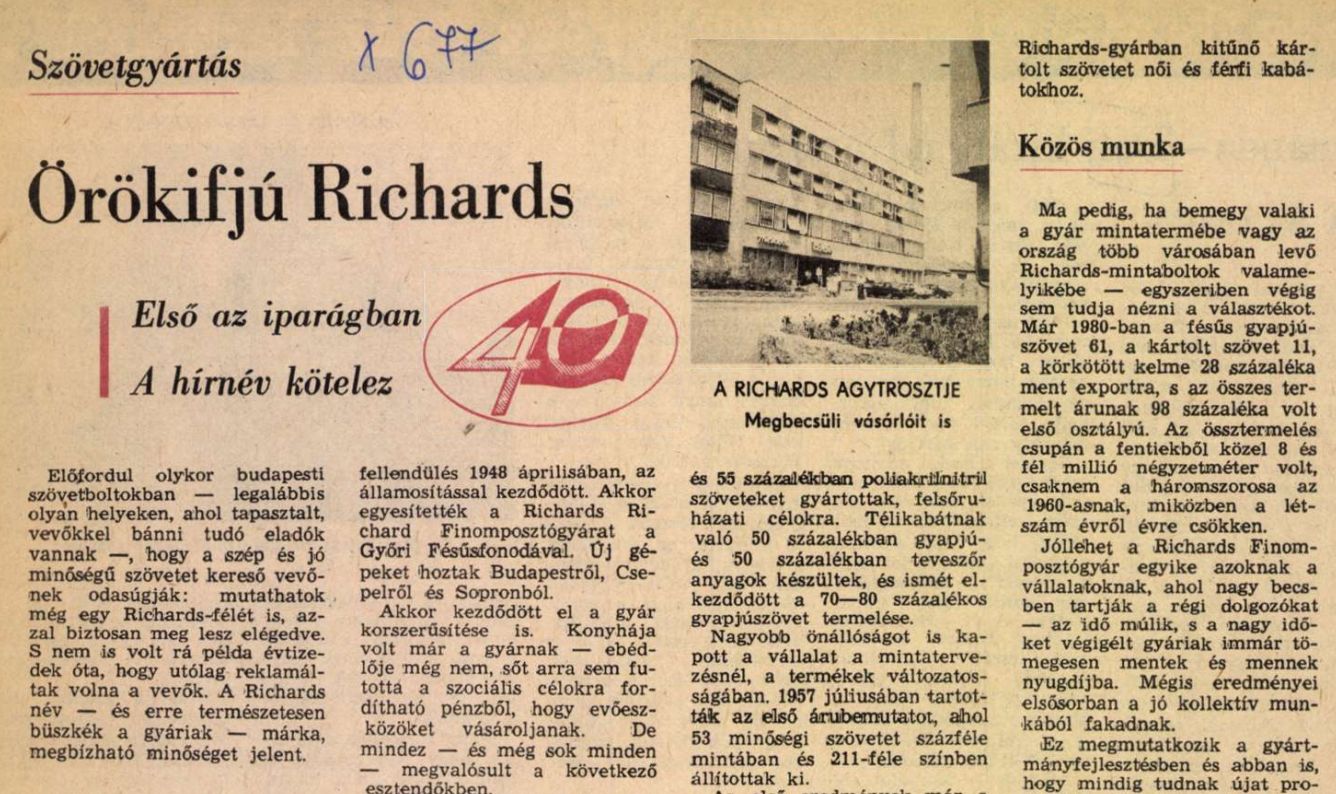

A one-page advertisement titled Richards Stands Up to Market Competition in the September 1973 issue of Kisalföld reports on the company's successes.

Fésülde in 1973

Knot in 1973

The factory entrance in the 70s

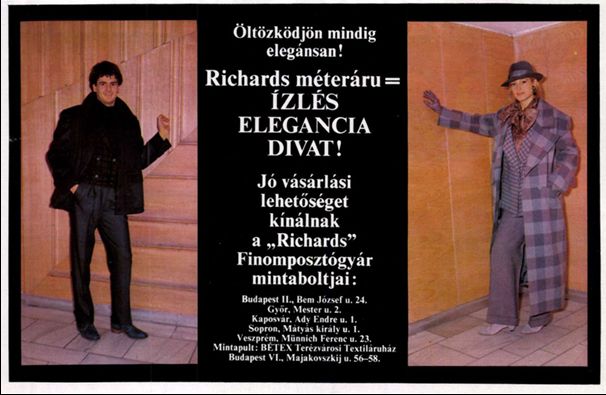

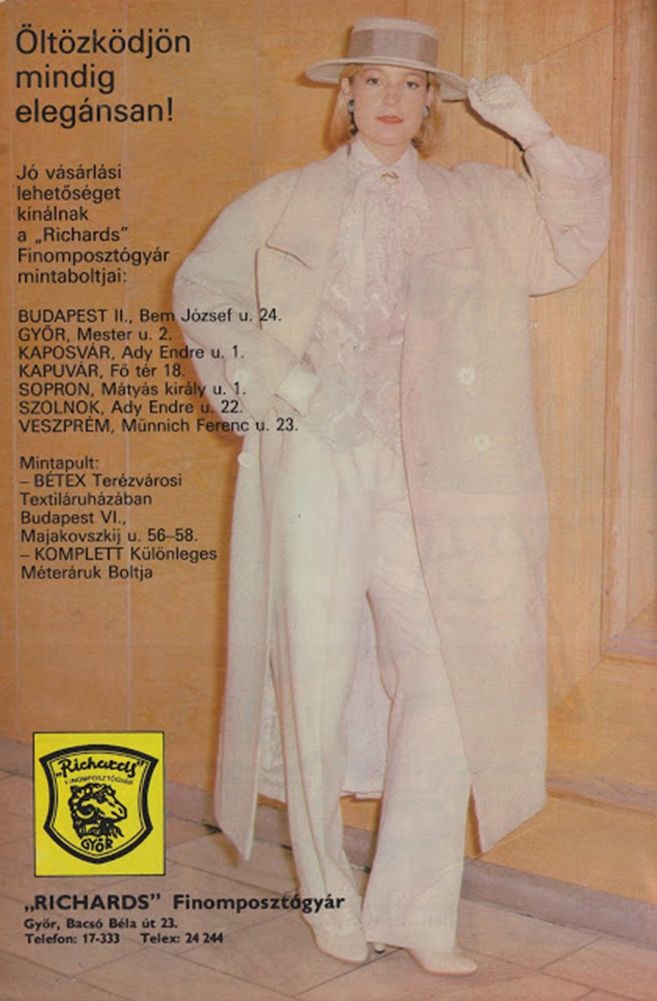

The company opened model stores in several cities across the country.

The Richards model store in Győr in the 1970s.

Over the years, it became increasingly difficult to maintain the existing Western markets, because the factory could not fully satisfy the growing quality expectations of consumers. The market situation was further worsened by the fact that demand from the CMEA countries also decreased. Low wages and the three-shift work schedule led to permanent labor problems. In the mid-1980s, the production value of the factory, which employed nearly 3,000 workers, including the rural sites, exceeded 4 billion HUF. One fifth of the country's cotton fabric production was produced in Győr.

Office building and model store in the 70s

The 1981 card calendar features the sample stores and the factory's ram's head emblem.

Source: http://www.kartyanaptarak.hu/displayimage.php?album=92&pid=4218#top_display_media

The Richards Fine Pastry Factory workers received the Pro Urbe award from the city of Győr in 1980. The recognition was featured on the 1981 card calendar.

Source: http://www.kartyanaptarak.hu/displayimage.php?album=92&pid=4219#top_display_media

In the 1980s, no further reconstruction took place, so the machines became old and outdated. The slow deterioration of product quality began when consumer demands shifted towards quality. It became increasingly difficult to pass on the cost of expensive raw materials from Western imports in the price of the finished product. Due to the difficulties of farming and the salaries lagging behind the wage levels of surrounding companies, the spontaneous emigration of the workforce accelerated. From the mid-1980s, the profitability indicators of farming began to deteriorate slowly but definitely. Stocks grew, orders became smaller, but production was nevertheless increased. State support for exports to socialist countries decreased due to the deteriorating budget situation, and loan interest rates and bank costs rose.

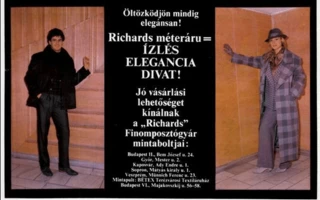

The full-page advertisement published in the press reports on the continued success:

Detail. Hungary, December 22, 1985, No. 51-52, p. 36.

In 1988, corporate profits fell to nearly half of the previous year, which did not allow the creation of development funds necessary to replace the machinery that had been written off to zero in the fifth year. The drastic increase in the price of raw materials, the frequent devaluation of the forint, and the severely limited bank borrowing caused increasing difficulties in daily management.

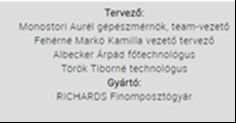

Award-winning Neckar outerwear wool fabric collection in the 1988 Industrial Design Excellence Award competition.

WORKS OF CREATORS AWARDED BY THE MINISTRY OF CONSTRUCTION AND URBAN DEVELOPMENT

Source: https://www.sztnh.gov.hu/en/testuletek/mft/formatervezesi_dij/dijarchivum/1988/640/2343.jpg

The intensification of the problems is also indicated by the frequent change of personnel in the top management position of the company. The cooperation with the Sopron Worsted Yarn Factory Subsidiary was terminated on December 30, 1991. The Kapuvár plant was closed, the building and the machines were sold. The company still had a loan debt of 450 million forints, which they wanted to exchange for shares at Magyar Hitel Bank. The wool production department of the factory was bought by the Italian Roberto Lanza. However, these measures could not save the company, during the bankruptcy proceedings that began in early 1992, no agreement could be reached with the creditors, so the liquidation of the factory began in the fall of 1992. Production and trading continued for a few years in small limited liability companies that mushroomed on the ruins of the factory, while the appointed liquidator tried several times without success to sell the factory.

Models made from Richards factory products:

Source: http://retromagyarfotomodellek.blogspot.com/2016/12/richards-finomposztogyar-modellje.html

The three-story office building of the Richards Fine Food Factory, the factory kindergarten and the staff apartments have already been sold. The cultural center, which can accommodate 500 people and was renovated in 1985, now serves religious life. The boathouse on the Danube was demolished after years of being abandoned.

The boathouse of the Richards Fine Pastry Factory stood near the Kossuth Bridge, on the banks of the Mosoni-Danube. 1967.

Source: fortepan/Inkey Tibor

A restaurant was set up in the factory building and observation tower on the factory grounds. The workers' quarters on the factory grounds were converted into a hotel. The materials that could not be sold during the liquidation were destroyed by fire on June 20, 2012. Life in the factory grounds came to a standstill, the brick fence surrounding the factory grounds was dismantled, and countless small shops were set up. The number of employees in these many new facilities is less than 2% of the former factory workers.

The compilation was prepared using the study of Mrs. Orbánné Dr. Márta Horváth.

See also: Éva Némáné Kovács: 150 years since the birth of Richards Ágost Richard (1867-1942), a major entrepreneur and founder of the Richards textile factory in Győr. In. Győri Salon, HELYBENjárás

| INTERESTING FACTS |

|

Festive snack of 300 working children in the large hall of the new community center.

The community center was established on the initiative of Nándor Kertész, the director of the Rt. The building was designed by Aladár Münich and constructed by Béla Marschall from Győr. The community center had baths, a large lecture hall, a dining room, a stage with stage sets, dressing rooms and cinema equipment, a library and a club room to facilitate cultural relaxation after work. There was also a doctor's office in the building.

Tihanyi Arpad Street 23. Photo:http://www.hotelalfa-gyor.hu/?page_id=416

|

||

|

Name variations: Richards Richard Cloth Factory 1908- Richards Richárd Fine Pastry Factory Ltd. 1918- Győr Combing Mill Co. Ltd. 1940- Richards Wool Spinning and Weaving NV (merger of Richards Richárd Fine Yarn Mill and Győri Combing Mill) 11 March 1949.- Győr Wool Spinning and Weaving Factory (with the annexation of the Győr Wool Spinning, Weaving, Dyeing and Finishing Factory Co.) 1951- Richards Woolen Spinning and Weaving Factory 1957- |

||

| LITERATURE |

- 2014. Orbánné Márta Horváth: The transformation of the textile industry in Győr from 1985 to the present day (in: The history of the Richards Fine Paper Factory p. 173-174.) In: Driving forces of Győr's development. The Győr automotive industry district as a new direction and tool for regional development. Monographs of the research 1. Editor. János Honvári. Published by Universitas-Győr Nonprofit Kft. Győr. p. 158-178.

- 1992. Richards Fine Paper Mill. Győr, Richards Fine Paper Mill. 47 pages.

- 1985. György Léhner: History of the "Richards" Fine Pastry Factory from 1905 to 1980.

- 1985. Ever-young Richards. New Hungary, December 22, No. 51-52, p. 36.

- 1973. Better quality, greater selection – at unchanged prices. Richards stands up to market competition. Kisalföld, September 16, No. 217.

Additional resources:

https://www.gyoriszalon.hu/news/10377/63/150-%c3%a9ve-sz%c3%bcletett-Richards-Richard-%c3%81go st-1867-1942-grandfather%c3%a1llalkoz%c3%b3-a-gy%c5%91ri-Richards-textilgy%c3%a1r-alap%c3%adt%c3%b3ja

Related gallery

Back to the previous page!