Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

MÁVAG F Factory

| MEMORIAL SITE ADDRESS, ROUTE PLANNING |

Győr, Puskás Tivadar Street 8.

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

The former site, best known and mentioned by the people of Győr as the “Tool Factory”, can be found at 8 Puskás Tivadar Street. The memorial disc is in front of the entrance, the one on the right is in the pavement, and the memorial plaque is in the green area inside the gate, mounted on a pedestal.

The area between Kandó, Ipar and Puskás Tivadar Streets originally belonged to the cannon factory, which was later divided into several smaller parts. MÁVAG once operated on the largest plot accessible from Puskás Tivadar Street.

On the street front, it is worth seeing the still-extant high brick wall fence of the former cannon factory , with concrete spheres symbolizing cannonballs decorating the tops of the columns.

The ruined building of the former reception service can still be seen next to the entrance to the site . Today, there are many businesses operating in the area, so the factory buildings are not open to the public .

During a walk around the site, starting to the right of the gate, you can see a few old buildings from the outside and a multi-storey bunker built on the site .

Street View:

Tudta-

Pictures from our days:

The Cannon Factory and the former site of MÁVAG

Photo: Zsolt Andorka

The characteristically designed skylights of the industrial halls

Photo: Zsolt Andorka

The roof of the multi-story bunker building that still stands in the middle of the site, with the reinforced concrete lookout for the air defense observation post.

Photo: Zsolt Andorka

| BRIEF OVERVIEW |

|

In Győr, we know of two significant factory openings during World War II. One of the new factories was certainly the Győr branch of MÁVAG, which was established in 1942 on the former site of the former Hungarian Artillery Factory Co. Ltd. (after World War I, its name changed to Győri Ipartelepek Co. Ltd.). The new name of the now nationalized company was Országos Villamossági Co. Ltd. The wagon factory played an important role in the establishment and equipment of the war plant , where artillery ammunition cases, assault helmets, parts for Turán and Nimród armored cars were manufactured and experiments were also carried out with the anti-tank mace, which was deployed at the very end of the war. In 1947, the MÁVAG Győr plant was attached to the Wagon Factory, and the official name of the plant became the Ipartelepi Wagon Factory. The former MÁVAG branch operating at the Ágyúgyári plant was separated from the Győr Wagon Factory in the summer of 1951 specifically for the purpose of producing munitions. The primary task of the independent Győr Machine Tool Factory was to manufacture the base and carriage structure of the 1939 model Soviet anti-aircraft machine gun. They also produced towed, mobile power generating units and other products for the army. Later, agricultural machinery (tractor trailers, agricultural trailers, combine straw collection wagons, hydraulic lifts), and hand and horse-drawn agricultural tools were also manufactured in the machine factory. On January 1, 1964, the Győr Machine Tool Factory was merged with the Hungarian Wagon and Machine Factory under the name Wilhelm Pieck Vehicle Works . Today, countless small and large enterprises operate on the site. |

| DETAILED COMPANY HISTORY |

In Győr, during World War II, we know of two significant establishment of factories. One was the Győr Iron Works, the other was the Győr site of MÁVAG (Hungarian Royal State Iron, Steel and Machine Works) . The minutes of the 1943 board of directors of the Wagon Factory show that the Győr company was commissioned by the government to organize a new company. The management of the construction and factory equipment was entrusted to the Wagon Factory and most of the equipment for the new enterprise was intended to be manufactured in Győr. This was not about expanding the Wagon Factory, but clearly about founding a new, independent company , which, according to the board of directors, "will operate in close connection with our company, insofar as we will have to assume the management and technical management and we will be obliged to produce and provide the components of the new company's products."

There was no free labor available in Győr and its surroundings at that time , and the Wagon Factory itself was struggling with a constant labor shortage. Since the new facility required additional workers, the “competent authorities” ordered the relocation of some of the Wagon Factory’s plants to “more favorable regions” in terms of labor , such as Salgótarján, Borsodnádasd, Ózd and Budapest, so that the local labor thus released could be transferred to the new factory. The relocation did not take place due to the upcoming bombing.

The most impressive production hall of the Győr Machine Tool Factory currently functions as a warehouse.

A former blacksmith shop, which many call the Eiffel Hall due to the style of the iron structure.

Photo: dr. János Honvári, 2017.

The new factory is certainly the Győr branch of MÁVAG, which was established in 1942 on the site of the former Hungarian Artillery Factory Co., Ltd., which changed its name to Győri Ipartelepek Co., Ltd. after World War I and became fully state-owned with the purchase of Skoda's share of the factory. MÁVAG's Győr plant produced cartridge cases during the war, so due to military secrecy, the press wrote very sparingly about the investment.

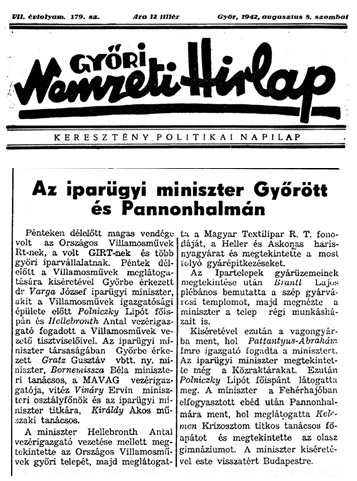

However, we can be almost certain that when the plant changed its name again in May 1942 (Országos Villamossági Rt.) and increased its share capital from 3,350,000 Pengő to 6 million, this transaction was aimed at establishing the MÁVAG branch, which had already been decided upon at that time. The local daily, Győri Nemzeti Hírlap, reported on the visit to Győr of the Minister of Industry and the CEO of MÁVAG, during which they inspected the “factory construction works” currently underway at the OVIRT (formerly Ágyúgyár) plant in August 1942.

Győr National Newspaper, August 8, 1942.

Source: http://edok.gyorikonyvtar.hu/

This could of course only have been the Győr site of MÁVAG, in the establishment and equipment of which the wagon factory played an important role. At that time, the Győr site of MÁVAG began to produce munitions . Artillery ammunition cases, assault helmets, parts for Turán and Nimród armored cars were manufactured here and experiments were made with the anti-tank mace, the so-called “Szálasi candle”, or volley, which was deployed at the very end of the war, but its mass production was no longer carried out.

44M Mace Thrower (Szálasi-röppentyű)

source: https://www.google.hu/

At the end of 1944 , the MÁVAG Győr plant was relocated to Germany (Zundorf) , and equipment worth 64,253,000 gold pengős was taken out. The factory was left with minimal stock and deprived of its machinery, and at the end of the war, only 23 people worked to clear the ruins and restart production.

MÁVAG occupied only part of the former Cannon Factory, sharing the use of the halls and buildings of the area with the National Electricity Company, which was also under the supervision of the Ministry of Industry.

Production in the dismantled, looted Industrial Estates began in the fall of 1946. In the inflationary times following the war, consumer goods (enameled stoves, dishes, agricultural tools, carts, seeders, etc.) that could be exchanged for food were produced – usually with low efficiency, poor organization, and low profitability . Seeders, for example, were assembled upstairs, all materials and parts were lifted there by crane, and then the finished machines were lowered to the ground by crane.

Beautiful woman stove

The stoves were manufactured in three different workshops located 100–150 meters apart, so the material traveled a long way around the factory.

The Wagon Factory and the MÁVAG Győr site were still two independent plants when, after World War II, a former artillery hall on the site was rented on April 12, 1946, with the approval of the governing authority, for the production of broad-gauge railway gondola cars delivered for Soviet reparations, which was from then on called Wagon II.

The former Vagon II. building still stands today.

Photo: dr. János Honvári, 2017.

Soviet reparations ended in January 1953, but freight car production did not, and this continued as long as railway freight car production continued in Győr. In the late 1950s, for example, tipper wagons were made here for Albania, pig transport wagons for MÁV, and 63 cubic meter tank wagons for various users.

The former Wagon II. building, the assembly hall in 2017

Photo: dr. János Honvári

In August 1947 , the Heavy Industry Center, which managed the nationalized companies , decided to attach the MÁVAG Győr plant to the Wagon Factory. From then on, the plant's official name became the Ipartelepi Wagon Factory.

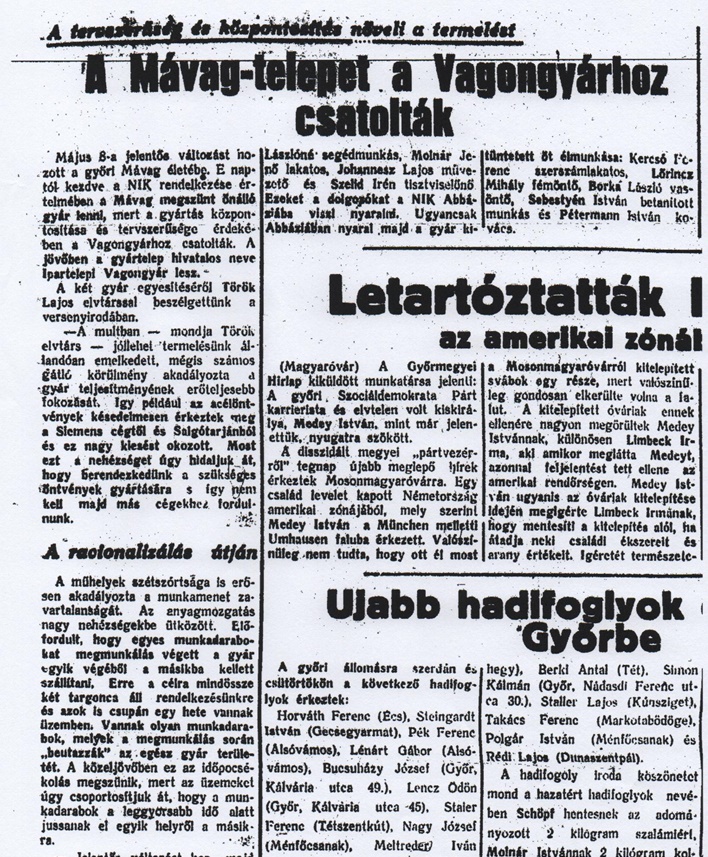

Excerpt from an article published in the Győr County Gazette, May 14, 1948

The idea of connecting the Wagon Factory, which was severely destroyed in the war, and the MÁVAG department, which suffered minor damage and was located close to each other, was proposed by the Wagon Factory managers themselves in early 1947.

The former MÁVAG branch operating at the Ágyumgyári site was separated from the Győr Wagon Factory by the governing authority in the summer of 1951 specifically for the purpose of producing munitions. The primary task of the independent Győr Machine Tool Factory was to manufacture the base and carriage structure of the 1939 model Soviet anti-aircraft machine gun. (The gun itself was manufactured in Diósgyőr and mounted on the towing structure there.)

37 mm anti-aircraft gun

In addition, they also produced towed, mobile power generating units and other products for the army. In the autumn of 1951, the Kossuth Prize-winning Stakhanovist lathe operator Ede Horváth was appointed director of the military plant, the Győr Tool Factory. When the MÁVAG plant was separated, the foundry operating in the Industrial Plant was also attached to the Tool Factory, which shortly afterwards became independent under the name of Foundry and Forging Factory , and from 1963 it became the 3rd factory unit of the national foundry company.

The “rapid development” of the Győr Tool Factory began in 1952. In 1953, the new TMK and tool factory were built, as well as a series of social facilities. During the “new phase” marked by the name of Prime Minister Imre Nagy, agricultural machinery (tractor trailers, agricultural trailers, combine straw collectors, hydraulic lifts, aggregates), manual and horse-drawn agricultural tools, and consumer goods (enameled stoves) were produced here in addition to/instead of “special products”. We know from interviews with former engineers of the company that in the mid-1950s, the Győr Tool Factory was also intended to be included in the program aimed at dieselizing the railways, within the framework of which the outdated steam locomotives were to be replaced with more modern electric and diesel locomotives and multiple units. For the sake of this project , the construction of the 8,000 m² hall that still exists today began in 1955 with a 5.5 million HUF cost-reduction loan . Construction stopped in the fall of 1956 due to the uprising that broke out, and only resumed in the second half of 1957.

Hall 8000, built during the time of Ede Horváth.

Photo: dr. János Honvári, 2017.

In the late 1950s, the new 8,000 square meter hall that still exists today was originally intended to produce railway diesel engines. Instead, in 1960, this hall accommodated the transmission factory that had been relocated from the wagon factory due to lack of space. When the relocation of the Transmission Factory, which had been wedged into the wagon factory area, from the main factory area was repeatedly discussed in the late 1950s, the new, modern hall at the time came in handy for Edén Horváth, as the Transmission Factory could be installed here without any new construction investment . From then on, road vehicle transmissions played an increasingly important role in the factory's profile.

Hall 8000, built during the time of Ede Horváth. The Gearbox Factory moved here in 1960.

Photo: dr. János Honvári, 2017.

The development of chassis production was based on an existing profile, as the Wagon Factory had long traditions of manufacturing rear and front axles. Between the two world wars, chassis were manufactured for road vehicles (buses, trucks, military vehicles) manufactured here, and then in 1949, after the profiling of road vehicle production, the Transmission Factory, which was organizationally separated from the Wagon Factory but geographically located in its old location, on the territory of the main factory, continued the production of this traditional product.

The gear factory, which operated from the car department on the wagon factory's premises, first became an independent factory (Győr Car Factory), then the plant operated as the Gear Factory of the Csepel Car Factory, became independent again between 1957 and 1960 (Győr Gear Factory), and finally merged into the Győr Tool Factory , which was also separated from the Wagon Factory . The screw factory operating at the airport operated independently under the name of Győr Screw Factory between 1951 and 1954 , became the Győr branch of the Budapest Screw Factory from 1954 to 1960, then merged into the Győr Gear Factory from 1 July 1960 and was transferred to the Győr Tool Factory at the turn of 1960/61. From then on, until the construction of the new airport landing gear halls, the chassis production was carried out on the premises of the Tool Factory.

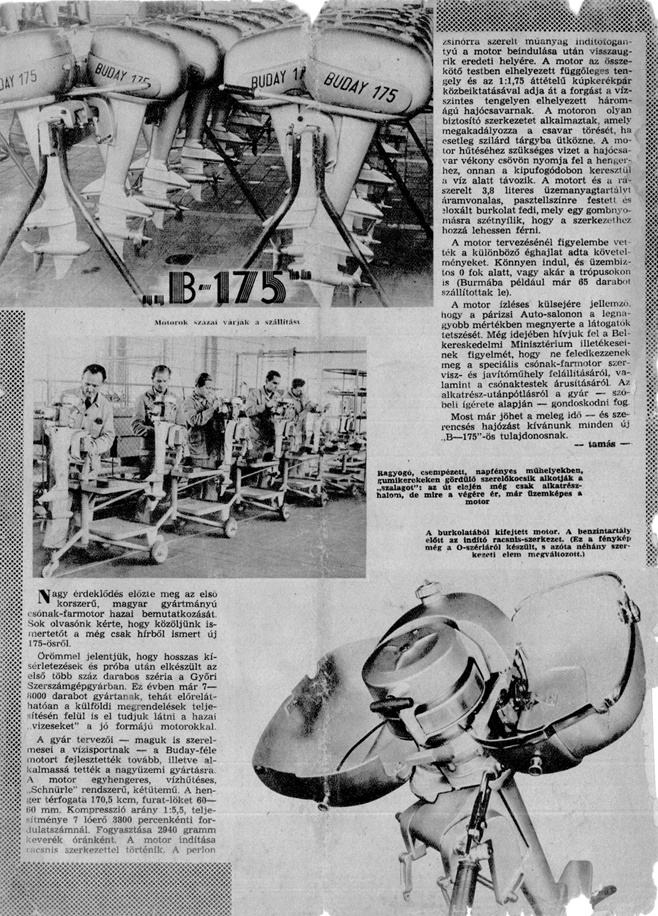

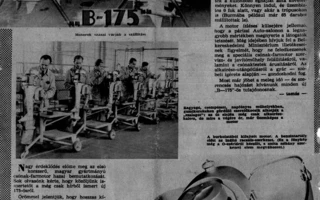

The production of anti-aircraft guns was completely stopped after 1956. They tried to use the freed capacities by manufacturing air brake compressors for Zetor and U-28 tractors, tractor parts, and transformers , but the production of stoves also continued at a rate of 30,000 units per year . In addition, in 1958-59, 175 cubic centimeter boat engines were also manufactured, a total of about 8,000 units. The license was purchased from a Hungarian designer, Béla Buday. As an experiment, a prototype of a 350 cubic centimeter boat engine was also made. The product was not successful from a design or market perspective.

Boat motor with the logo of the Győr Machine Tool Factory

At the end of the 1950s, the modernization of railway traction was also on the agenda in Hungary, within the framework of which the outdated steam locomotives were gradually replaced with electric and diesel locomotives. In addition to satisfying domestic needs, they wanted to export a large number of the 600 HP diesel-electric locomotives to the Soviet Union. At the end of 1957, the Győr Machine Tool Factory was selected for the production of the so-called traction electric motors and main dynamos that drive the diesel-electric locomotives . The fact that the Győr factory could not use a significant part of its capacities by discontinuing the production of anti-aircraft guns certainly played a role in the decision. In addition to the production of traction motors and main dynamos, KGM wanted to develop the Machine Tool Factory into one of the domestic bases for the production of transformers. The state provided an investment budget of 81 million 592 thousand HUF to start the production of new products. The majority of the construction investment funds (25.6 million HUF) were spent on the completion of hall 8000, the rest was mostly purchased from socialist countries, and the new cutting plant, a 600-person male and female changing room and bath, some smaller warehouse buildings and the transformer house were also completed from this source. To implement this program, but with 6.5 million HUF provided specifically for this purpose, a so-called “parrot housing estate” of 11 houses, 4 each, a total of 44 identical, modern, district heating, garages and basements was built in the immediate vicinity of the factory , which aimed to attract electrical engineers and technicians to Győr, who were indispensable for the production of high-voltage machines. The housing estate got its name from the fact that each house was painted a different color.

Photo: Dr. János Honvári

The common yard was fenced off, and in the first period, a reception service was also operated at both ends of the complex. In the landscaped area, children could play safely, without parental supervision, in the sandbox and paddling pool created for them.

The production of Hungarian diesel-electric locomotives was not economical, so in the early 1960s the management of the Machine Tool Factory again had to face the danger that the factory's ever-expanding capacities would not be able to be exploited due to a lack of work and orders. The factory's capacities were again tied up with military orders in the early 1960s . During the Kádár era, complete components, front and rear axles, and transfer cases were manufactured here for the Csepel Autógyár's D 344 all-wheel drive off-road trucks (primarily used for military purposes), and in cooperation with several other factories, the Győr Machine Tool Factory became the center for the production of reconnaissance floating vehicles (FUG), and a few years later, as a department of the Wagon Factory, the D-944 armored combat transport vehicles (PSZH).

Armored fighting vehicle (APC) In factory jargon, these monsters were called "water chicks"

With this change in profile, the Győr Machine Tool Factory once again became the most important military industrial plant in Győr-Sopron county. In 1961, the Machine Tool Factory received an investment opportunity of 49.6 million HUF from the governing authority to start the production of the D-344 type all-wheel drive truck, and in 1962 and 1963, a total of 69.6 million HUF to organize the production of the FUGs. In order to produce the two military vehicles, the machines in hall 8000 of the Machine Tool Factory were rearranged, and a conveyor belt and transfer line were built for material handling.

Reconnaissance floating vehicle (FUG)

With the relocation of the Engine Factory, the production of boat engines and agricultural trailers was discontinued. For a short time, the traction engine and main dynamo of diesel-electric locomotives were still produced – in a much smaller series than originally planned – but this was soon abandoned. From the beginning of the 1960s, capacities were increasingly taken up by the production of complete engines and engines for armored amphibious combat vehicles (FUGs, PSZHs), as well as all-wheel drive off-road trucks.

In 1963, Ede Horváth was appointed CEO of the Győr Wagon Factory, while simultaneously retaining the position of director of the Machine Tool Factory. On January 1, 1964 , the Győr Wagon Factory was merged with the Hungarian Wagon and Machine Factory under the name Wilhelm Pieck Járműipari Művek . Today, countless small and large enterprises operate on the site.

The compilation was based on the study of Dr. János Honvári.

Continue to the detailed study

| INTERESTING FACTS |

|

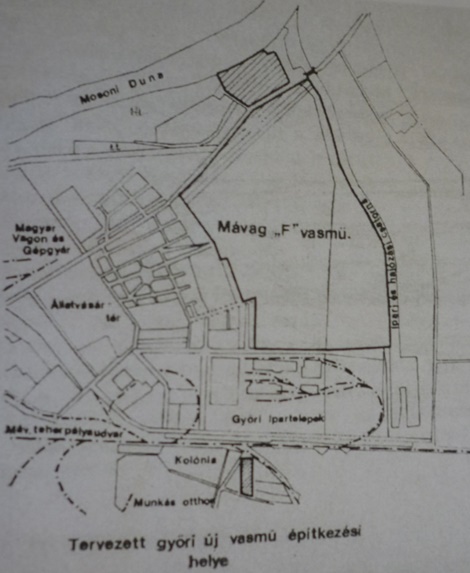

During World War II, in addition to the MÁVAG Győr plant, the construction of the Győr Iron Works was also started in the area bordered by Puskás Tivadar Road, Ipar Road, Budapest-Vécs Road and the Industrial Canal, but the construction was ended by the repeated bombing of Győr. The importance of Győr's industry is indicated by the fact that Győr was also among the possible sites for the installation of the light metal plant built during the war, in addition to Székesfehérvár. When, after the signing of the German-Hungarian Aviation Agreement of 1941, it was decided that one of the production bases for combat aircraft would be Hungary, which had significant bauxite resources, the Hungarian Bauxitbánya Rt. signed an agreement with the German Dürener Metallwerke AG on June 25, 1941, to produce the aluminum products necessary for the production of aircraft. There were many arguments (old industrial traditions, the existence of a wagon factory, an aircraft repair plant, etc.) in favor of Győr, but the light metal plant was ultimately built in Székesfehérvár. |

|

How in the March 1, 1958 issue of Autó Motor there was a full-page article reporting on the trial production of B 175 boat engines at the Győr Machine Tool Factory? Boat motor advertisement |

|

Name variations: Győr Industrial Estates Co., Ltd. 1942 National Electricity Company May 1942 – Ipartelepi Wagon Factory May 1948 – Győr Machine Tool Factory 1951 – Wilhelm Pieck Automotive Works 1964 – |

| LITERATURE |

- 2014. Pál Germuska, János Honvári: The history of road vehicle manufacturing in Győr from 1945 to 1990. In. Driving forces of Győr's development. The Győr vehicle industry district as a new direction and tool for regional development. Research monographs 1. Győr, Palatia Nyomda. pp. 21-111.

- 2008. Ádám Varga: The Hungarian Wagon and Machine Factory and the military orders. In: Military vehicles of Hungarian car factories. Edited by: Varga A. József. Maróti Publishing House, Budapest, pp. 405-406.

- 1996. Rába 1896-1996. 5 copies. Published by the Rába Hungarian Wagon and Machine Factory Information Organization, Győr. Publications of the Rába Centennial Exhibition Center.

- 1996. Rába 1896-1996. Published by the Rába Hungarian Wagon and Machine Factory Information Organization, Győr.

- 1972. Zoltánné Tabiczky: The History of the Hungarian Wagon and Machine Factory 1896-1945. Volumes 1-2. Hungarian Wagon and Machine Factory, Győr.

- 1956. Géza Gárdonyi, Jr.: The History of the Wilhelm Pieck Wagon and Machine Factory in Győr, 1896-1956. Győr-Sopron County Printing House, Győr.

Related gallery

Back to the previous page!