Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Kohn's Oil Factory

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Related gallery |

| ADDRESS OF THE MEMMORIAL, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

Street view:

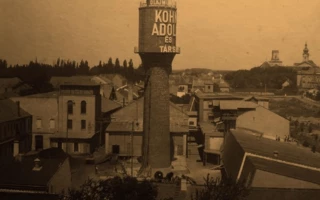

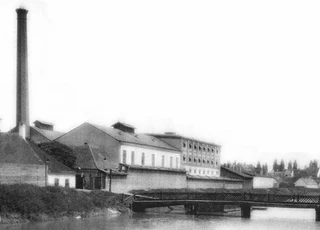

A picture from the past:

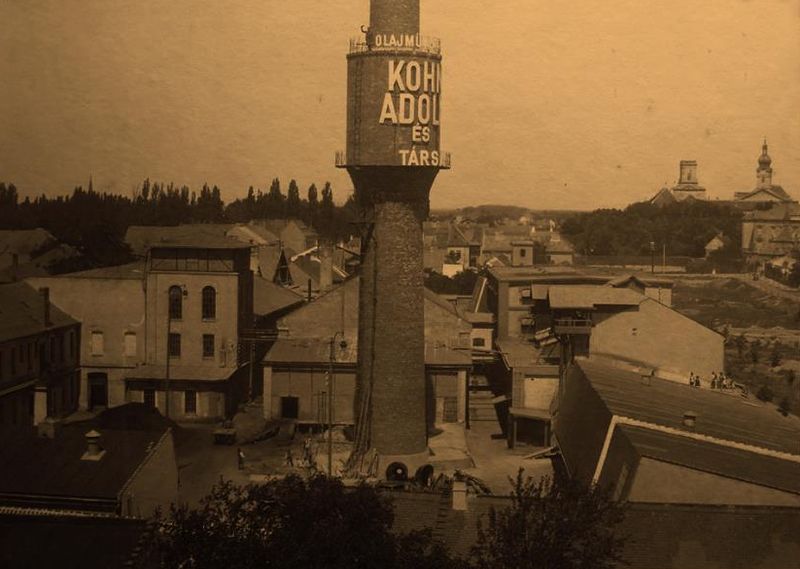

Oil factory around 1900. The picture shows the Krajcáros Bridge spanning the old bed of the Rábca.

Source: http://www.sze.hu/~htms/blog/berc/a01.pdf (Download: 2019.Nov.3.)

| BRIEF OVERVIEW |

|

Henrik Austerlitz and his brother-in-law, Adolf Kohn, founded the country's first vegetable oil factory, originally equipped with steam power, in Győrsziget in 1851. The family business, which initially processed rapeseed and linseed, changed to a joint-stock company in 1910. The factory's area and equipment were constantly developed, so that after Trianon, the Győr factory became one of the largest oil factories in the country. In 1931, the shares were acquired by the Anglo-Dutch company Unilever, which suspended production between 1932 and 1939. The factory survived World War II intact, by which time it was producing mainly sunflower cooking oil. In 1992, the Győr plant was privatized along with the entire Hungarian vegetable oil industry. Cereol ceased production in Győr in 2000 and sold the site, where apartments have since been built. |

| DETAILED COMPANY HISTORY |

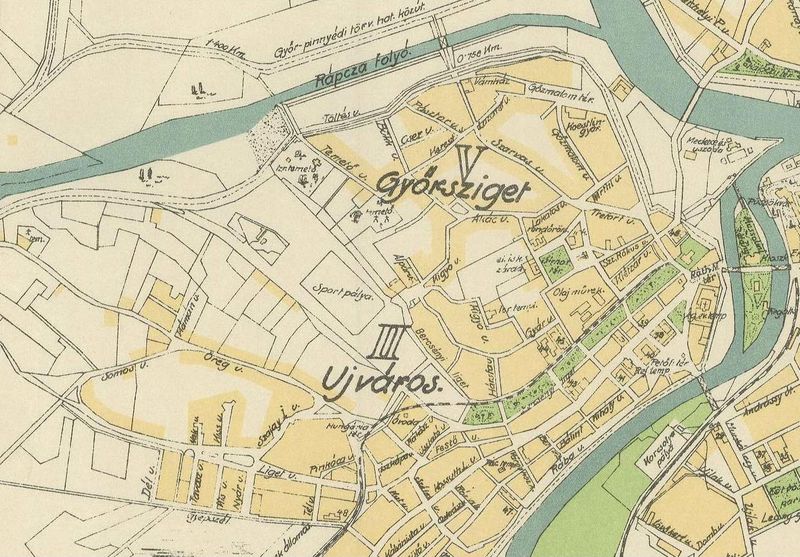

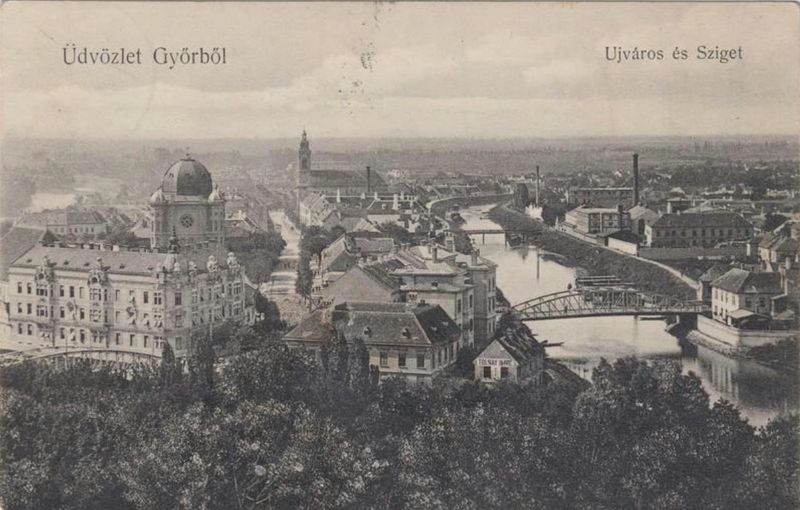

View of Újváros and Sziget before 1908, with the oil refinery in the background

The Austrian Henrik Austerlitz and his brother-in-law, Adolf Kohn, born in Jemnitz, Moravia in 1820, settled in Győrsziget in 1848, where they founded the country's first oil factory, originally equipped for steam power, in 1851, which reigned under many names and variations during its century and a half of operation.

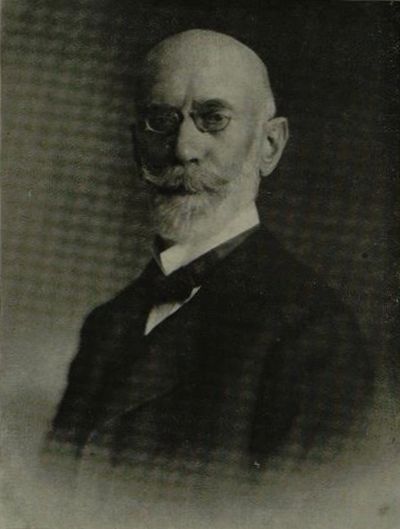

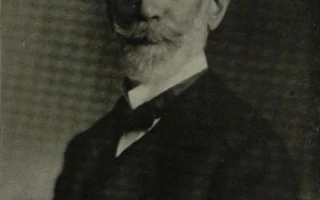

Kohn Adolf

Jemnitz, 1820 – Vienna, 1905.

Aladár Petz: The Past and Present of the Holy Trinity Public Hospital of the Free Royal City of Győr, 1749-1928. Győr, 1929. p. 197.

Source: https://edok.gyorikonyvtar.hu/book/-/record/33886;jsessionid=29E9E71B505874F875262101EDEDC575

Adolf Kohn acquired Hungarian citizenship and became a member of the Győr County Legislative Committee by virile right. His brother-in-law, Henrik Austerlitz, left the Győr Island oil factory in 1854, which was then registered under the company Kohn Adolf and Co.

Austerlitz built Győr's other large oil factory in the middle of the city, on the former Városszer, on today's Szent István Street, in the immediate vicinity of the Jedlik Ányos Vocational High School and Vocational Middle School, which began operating in 1877. The owner died two years after the oil factory was founded and the factory was continued by his heirs. Ignác Meller, who was an employee of this oil factory, became part of the family and thus came to have a controlling stake in the company, which was transformed into a joint-stock company in 1907. The factory, which was extremely fire and explosive, burned down in 1911 and was forced to move to a new location in Gyárváros, on a plot next to the road named after János Teleszky, the Minister of Finance of Hungary during the Dualism era, next to the former slaughterhouse, where the company went bankrupt and was liquidated in the late 1930s.

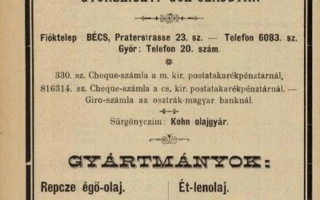

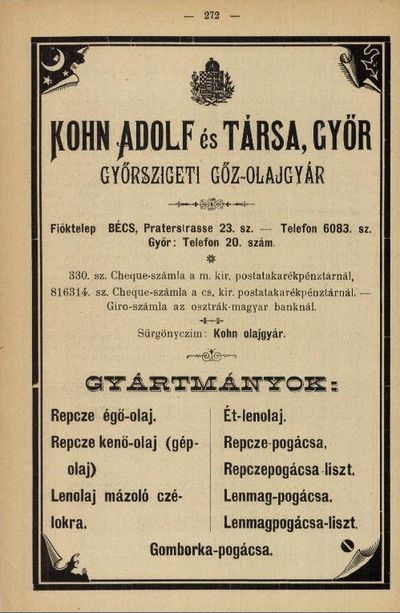

Kohn's Győr oil factory

Borovszky Samu: Counties and cities of Hungary, Győr County. 1908. p. 132.

Source: https://mek.oszk.hu/09500/09536/html/0009/9.html

The Győr Island plant primarily produced rapeseed oil for lighting purposes, while the Austerlitz-Meller oil factory produced linseed oil, which was used for wood preservation, painting, diluting oil paints, and later for the production of linoleum and artificial leather.

From the 1830s onwards, smoky, smelly and expensive candles made from tallow were gradually replaced by rapeseed oil, which was more suitable for lighting purposes. Although the main profile of the Győr Island factory was the production of rapeseed oil, in 1903 they also set up to produce linseed oil. The two seeds were never processed on the same machines. Rapeseed was processed in one half of the factory, linseed in the other.

Rapeseed field

By H. Zell - Own work, CC BY-SA 3.0,

Source: https://commons.wikimedia.org/w/index.php?curid=9378327

In Hungary at that time, vegetable oils were only used for food purposes for religious or economical reasons. In Austria, on the other hand, refined rapeseed oil was already being used for cooking and baking in the second half of the 19th century, so the factory's product was also shipped there for this purpose. The oil cake produced as a by-product was considered an important animal feed, and was also mostly exported, because in our country this by-product was rarely used for animal feed at that time.

View of Újváros and Sziget before 1908, with the oil refinery in the background

At the time of its founding, 10 workers worked in the 20-meter-long, 12-meter-wide factory built on the banks of the Rábca River and in the associated auxiliary facilities, who processed only 50 tons of oilseeds per day. Adolf Kohn personally managed the factory until 1874, then leased it to his first company manager, Miksa Gold. In 1886, he returned to manage the factory for a short time, then moved permanently to Vienna, where he worked at the Vienna company branch he had founded until his death in 1905 at the age of 86. He handed over the management of the Győr factory to his son, Ignác Kohn, who had a degree in mechanical engineering, who opened the factory's office in Budapest at 5 Báthory Street, V. District in 1900.

Szőgyi G. Vilmos: Ladies and Gentlemen, Győr's Millennial Calendar for the Year 1897. Győr, 1896. p. 278.

Like most food industry plants, the Győr oil factory used a large amount of agricultural raw materials, a lot of energy and water during its operation. In the first decades, rapeseed and linseed were the two most important raw materials, the production and purchase of which was carried out with the involvement of numerous large and small landowners, often by transporting them over long distances.

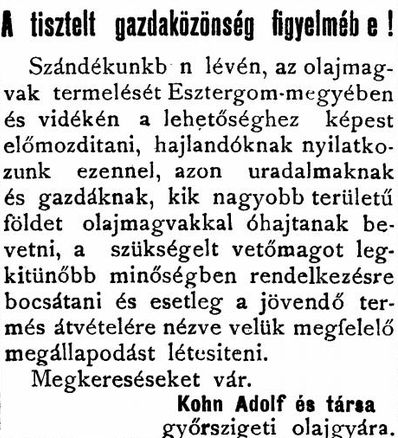

Esztergom and its region, 1902. No. 67. August 24. p. 4.

Source: https://library.hungaricana.hu/hu/view/Esztergom_es_Videke_1902/?pg=269&layout=s

Sunflower was not an important raw material until the end of World War I, as its cultivation only began in Hungary in the second half of the 19th century and it took time for it to spread. The importance of rapeseed oil decreased with the spread of petroleum and then electric lighting, and it was replaced by sunflower seeds. Since the eastern and northern parts of the country became the main producer of this oilseed, transportation distances (and thus costs) continued to increase.

The Kohn oil factory area, buildings – and even more so the plant’s equipment – were constantly expanded from the 1870s – but especially from the first decade of the 1900s. In the volume Győr County of the book series introducing the counties of Hungary, the editor writes about it as follows: “The industrial site expanded continuously, especially in 1870 and 1887, to the point that it soon became the first oil factory in the country. In 1890, the factory was completely rebuilt and equipped with the most modern oil presses and steam circuits. In 1903, the company also founded a linseed oil factory in connection with the rapeseed oil factory and installed a 400-horsepower steam engine to drive the factory’s plant, and at the same time it also set up a completely modern laboratory.” This investment cost around 2 million crowns. The boilers that produced energy (and then electricity) were modernized and expanded several times, driving an ever-larger steam engine (or a generator for generating electricity). At the beginning of the 20th century, a new cooperage workshop, press house, cake warehouse, chimney and boiler house were built. For further construction, the area of the plant was expanded by purchasing the plots around the factory and a bordering street. In 1905, for example, the oil factory purchased all the areas from the Masek house on Kletzár Street to the vinegar factory, where the factory expansion was planned.

Factory site

Source: http://arrabona-varosvedo.hu/2016/11/23/ez-a-kemeny-is-utban-van/

The Rábca riverbed in front of the factory was relocated in 1906, giving Győrsziget a direct land connection with Győr at today's Bercsényi grove. This caused further costs for the oil factory, as the direct transport of raw materials by ship to the factory area and the possibility of local water extraction ceased. The oil seeds had to be transported from the freight station to the place of processing, initially by horse-drawn carriages, and then by rail (partly by truck). The factory was responsible for building the industrial siding leading to the factory. The family business was no longer able to cover the significant additional costs resulting from the development, so the oil factory was transformed into a joint-stock company in 1910 with the cooperation and partly with the capital of the large Viennese bank, the Wiener Bankverein.

According to the factory history, in 1880, 80-100 workers worked in two continuous shifts, 12 hours a day, and in 1910, about 200.

When World War I broke out, the factories suffered from weeks of raw material and coal shortages. An export ban was imposed on all basic raw materials and foodstuffs, including vegetable oil. The news of the outbreak of war caused inflation and the purchase of durable food began. Despite the economic difficulties, the factory continued to develop during World War I and in the first half of the 1920s. Cooking oil was considered a strategic product during the food shortage, which was managed centrally by the state. The war boom promised huge profits for entrepreneurs, so the factory expanded its crude oil refinery, an extraction plant, a new method of extracting crude oil, an edible fat factory, and a gas plant for hardening cooking oil by hydrogenation. One of the streets bordering the factory was purchased, where five new plants were built between 1918 and 1923.

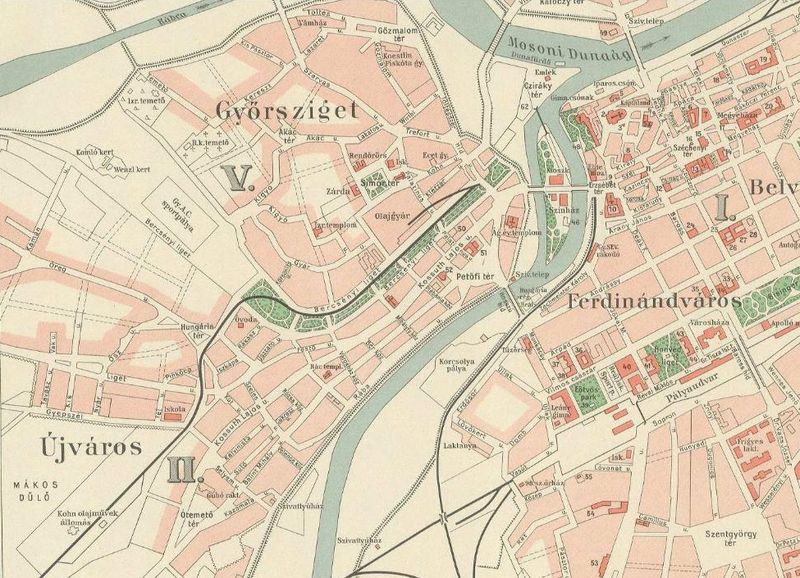

Detail from the 1930 map of the Free Royal City of Győr.

Between the two world wars, more and more experts in nutrition (and the public opinion in turn) believed that vegetable fats were healthier than animal fats. However, eating habits in Hungary changed only slowly, and cooking oil – especially among the rural population – did not become a real competitor to lard for a long time, even in the consolidated decades after World War II. Rapeseed oil for lighting purposes – after the introduction of kerosene and electric lighting – was mostly used to fill the moving lamps of railway marshals and traffic controllers. In Győr, in 1905 and 1912, two large-scale industrial users of linseed oil appeared, the Grab M. és Fiai artificial leather and waxed linen factory and the Keffel Ede waxed linen factory. The Győr Varnish Factory, founded on December 1, 1922, initially only dealt with the packaging of paints and oils, but in 1924 the production of oil varnishes began in our city, thus finding another large-scale industrial user of the products of the two Győr vegetable oil factories.

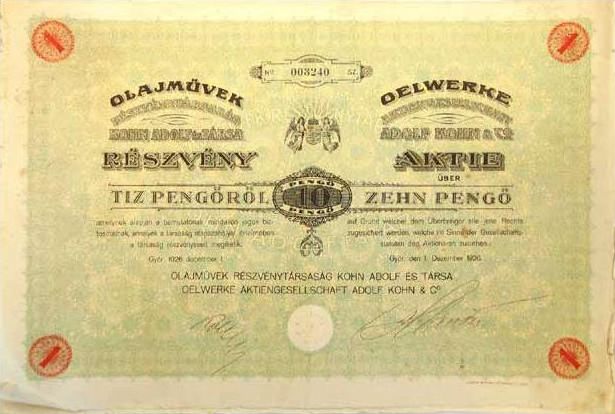

Between the two world wars, the two Győr oil factories were only able to utilize a small part of their capacities, partly due to the decline in the consumer market and partly due to the export of oilseeds in unprocessed form. The Kohn Oil Factory had its share capital increased several times to finance large investments. The company, which had taken out a significant loan from the Wiener Bankverein for the new investments, was unable to repay some of the loans, so in the 1920s the vast majority of the shares ended up in the vault of the Vienna bank.

Before the outbreak of the global economic crisis, statistics recorded six industrial vegetable oil factories in addition to the numerous small rural oil mills. Of these, the Győr industrial plant of Olajművek Rt. Kohn Adolf és Társa was the most significant. Meller Ignác és Társai Rt. and the Bonyhád Oil Factory Kohn Testvérek Oil Factory had essentially suspended operations for a long time.

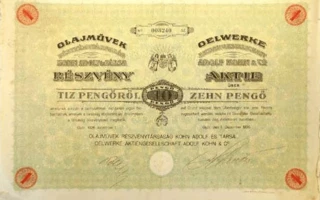

Oil Works Co., Ltd. Kohn Adolf and Partners 10 pengő shares. 12/01/1926.

Printed at the Légrády Printing and Book Publishing Company in Győr

Source: http://bedo.hu/index.php?azon=webuzlet&kkod=1&akod=0&asor=0&list_meret=25&list_kezd=175

In 1928, the Wiener Bankverein sold its share package in the Győr oil factory through a Berlin intermediary to the Anglo-Dutch multinational company, Unilever, which had acquired the largest vegetable oil factories of the disintegrating Austro-Hungarian Monarchy after World War I. Unilever's two Hungarian vegetable oil factories, Győr and Rákospalotai, were merged and placed under the control of the concern's English director stationed in Budapest. From then on, the history of the Győr company was closely linked to that of the Rákospalotai Vegetable Oil Factory for decades (apart from short periods of independent operation). The Rákospalotai factory began pressing vegetable oil in a mill in 1840. The oil factory was purchased by soap maker József Hutter in 1925 and renamed Hutter Soap Factory and Oil Industry Co. until Unilever acquired a 45% stake in the soap making oil factory in 1930. That is why the factories in Hungary owned by Unilever were called Hutter and Lever.

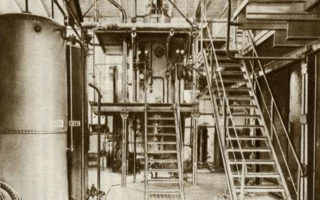

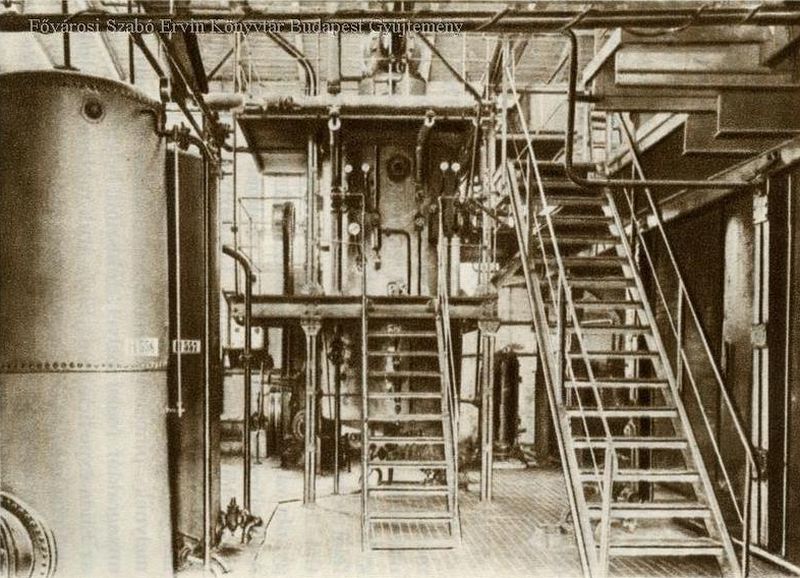

Edible oil and fat refinery at the Rákospalota factory of Hutter and Lever Rt.

History of Hutter and Lever RT: 1831-1931. - Budapest: [Globus Ny.], 1931. - p. 60.

Rights: FSZEK

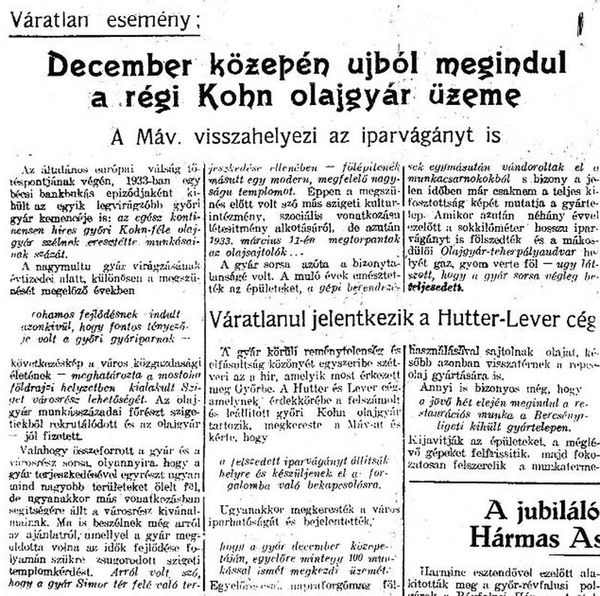

Due to the economic crisis, the new Anglo-Dutch owners shut down the Győr factory, laid off 400 workers, and continued to operate some of the machinery and equipment at Unilever's Rákospalota and Swiss plants. The boiler and power generating machines were sold, the railway tracks leading to the factory were removed, and production was suspended between 1932 and 1939.

The shutdown of the Sziget factory clearly indicates that the international concern had bought a market in Hungary, as from then on, domestic consumers were largely supplied with products from the multinational company's foreign companies.

Győr National Newspaper, October 1939. 11. No. 235. p. 3.

During the preparations for World War II, preparations were made to restart the two oil factories in Győr. The Meller Oil Factory was already producing in 1936, before the Hutter and Lever factories in Győr. It seems that in the case of the Győr Island oil factory, they did not expect a seven-year shutdown, because in 1932 they failed to take the necessary conservation measures during a long shutdown, they did not clean the pipes and machines, which caused them to become clogged and broken, and it was only after lengthy preparations that the plant could be restarted in the spring of 1940. During the war, they only produced crude oil, which was transported to the Rákospalotai Vegetable Oil Factory for refining.

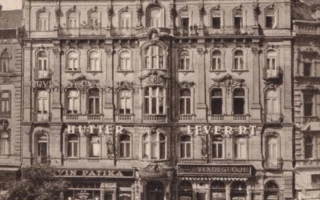

The central office building of the Hutter and Lever company in Budapest, at 6 Erzsébet-körút, in 1936

The factory survived the dozens of air raids and ground battles that hit the city during the last period of the war unscathed. Chief Engineer Jenő Klauerer prevented the retreating German troops from blowing up the boiler house, so the oil factory could have produced at full capacity if other conditions had been met. After the German troops withdrew, the starving population stormed the factory, wanting to obtain cooking oil. However, the looting was prevented, so work began here, as the first of the factories in Győr, by refining the crude oil remaining on the factory premises. The oil factory – like the other large factories in Győr – came under the control of the Soviet military commander.

The picture shows the installation on a truck of Hutter and Lever Rt. in 1948, based on the theme of sunflower, one of the company's important raw materials. The brand names of the two leading products are also clearly visible:

Liga margarine and Venus cooking oil.

Source: https://hu.museum-digital.org/portal/index.php?t=objekt&oges=34295&cachesLoaded=true

Amid the severe food shortages after the war, an oil refinery was put into operation in Győr with a small capacity in 1947 to supply the local population. However, the primary task of the Győr factory remained the production of crude oil, which was refined in the Rákospalota oil factory.

The Rákospalota and Győr oil factories and the Elida soap factory remained in the ownership of Unilever until the end of 1949, and their management was managed from Budapest. A few engineers and administrators organized production in the three factories. The serious explosion that occurred in the extraction plant of the Rákospalota factory at the end of 1947, which also claimed human lives, was used to make the Hutter and Lever companies economically impossible and to expel the English director from Hungary. Hutter and Lever were then placed under state control and nationalized in 1949.

The three factories operated as independent national companies until the summer of 1950, then came under the control of the Győr and Budapest vegetable oil industry associations six months later. The Győr factory operated as an independent company from 1953 under the supervision of one of the ministries until January 1, 1964, when, during the general merger of Hungarian industrial companies, it continued to operate as the Győr factory of the Vegetable Oil Industry and Detergent Manufacturing (National) Company, which included five similar vegetable oil industry companies, a research institute and a laboratory.

During the heavy industrialization economic policy of the 1950s, the oil refinery had little access to investment and development resources.

Initially, Vénus sunflower cooking oil was sold in glass bottles sealed with corks. Advertising calendar.

Source: http://storeinsider.hu/cikk/60_eves_a_magyar_haziasszonyok_kedvence

Between 1955 and 1974, linseed oil was no longer produced in Győr, sunflower oil became the main product, and the rapeseed oil produced was half to a third of the sunflower oil. However, soybean oil was also occasionally produced in small quantities.

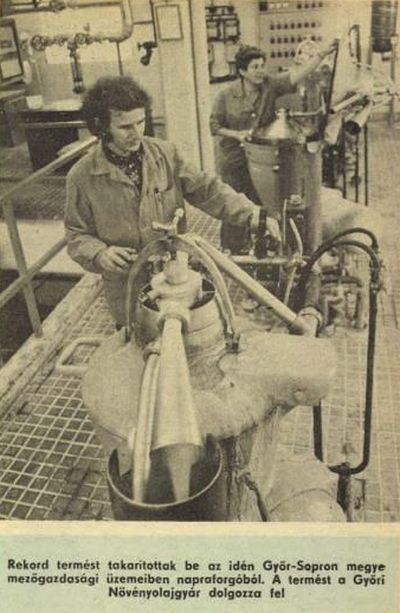

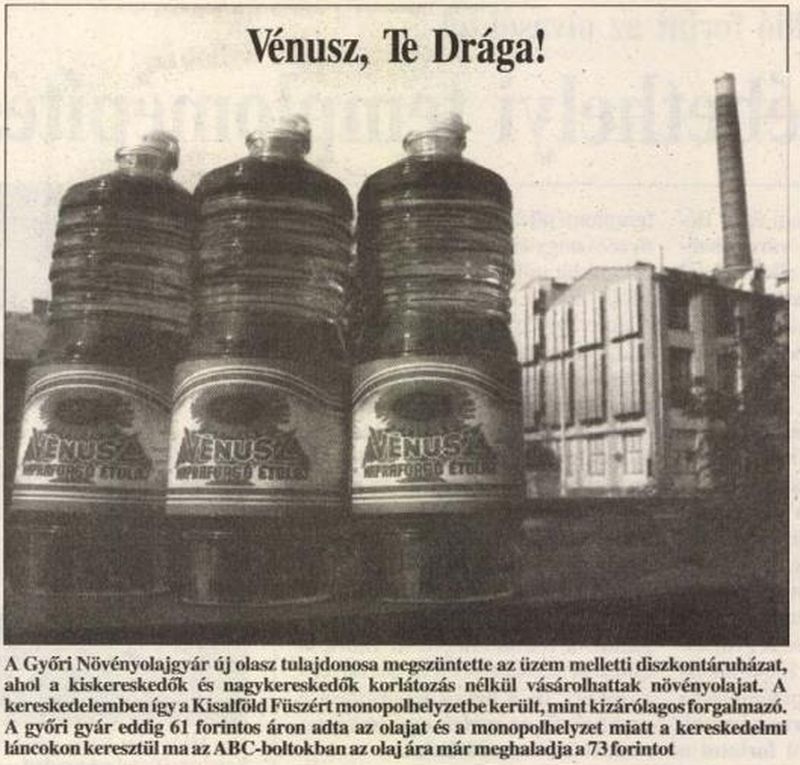

Venus sunflower cooking oil in PVC packaging on the production line

Source: https://www.marketinginfo.hu/markatortenet/article.php?id=37

The number of employees, which was 400 in 1950, decreased to 246 in 1972, while production tripled. However, production and productivity did not increase evenly. In the history of the factory, smaller quantities of bottled and barreled cooking oil were often produced. Since bottling was done with outdated machines in the mid-1950s, the packaging of Vénusz cooking oil was profiled for Budapest after 1955. In Győr, from 1956 for almost two decades, only crude vegetable oil was produced, which was refined in the Rákospalota factory. However, due to changes in domestic and foreign consumer demands, they switched to the production and bottling of refined sunflower cooking oil again in 1974.

In Hungary, the consumption of sunflower cooking oil began to grow rapidly in the early 1970s. In ten years, the per capita consumption of vegetable-based fats increased from 2.7 kg to 7 kg, which still left Hungary far behind compared to Western European and overseas countries. The modern bottling line of the Győr vegetable oil factory was set up in the existing factory building, where in the mid-1970s about 30,000 PET bottles were filled with Vénusz sunflower oil annually.

Venus sunflower cooking oil in older packaging

Source: https://www.marketinginfo.hu/markatortenet/article.php?id=37

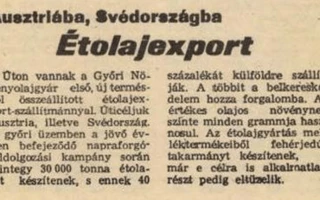

Due to the rapid growth of demand, the oil refining capacity was doubled in 1978. The production of bottled edible oil, which was around 3,000 tons in 1974, increased to 7,700 tons in 1976, 10,000 in 1977, and more than 12,000 tons in 1978. The high-quality crude sunflower oil could be sold on Western European markets for convertible currency. In the mid-1980s, 40% of the edible oil production of the Győr factory was exported to the West. After a new, modern vegetable oil factory was built in Martfű, the transportation for capital export became the primary task of this factory, and the Győr plant produced mainly to meet domestic needs. Production – as in all food industry plants processing agricultural raw materials – is also seasonal in vegetable oil production. They started with rapeseed in July, then sunflower processing began in September, which usually lasted until May. Then they stopped and performed the necessary maintenance.

Szolnok County Newspaper, 17 Jan. 1980, No. 13, p. 1.

Transdanubian Diary, Oct. 1984. 158. 4. p. 287. no.

In the late 1980s, shortly before the change of regime and the privatization of the factory, the Győr oil factory, which accounted for about 10% of domestic vegetable oil production, was modernized using a World Bank loan. The export-expanding and quality-improving investment was partly aimed at expanding the scarce storage capacity by building seven storage silos, each with a capacity of 3,500 cubic meters. The majority of the investment amount was spent on replacing and modernizing the pressing and extraction equipment.

Invitation to a product presentation. 1989.

Source: https://edok.gyorikonyvtar.hu/leaflet//record/29421;jsessionid=F9D6831DB626396A593D1E3DBF699214

As a result of the last major modernization before the change of regime, the sunflower seed processing capacity of the Győr vegetable oil factory increased from 220 tons in 1965 to 110 thousand tons, and the production of Venus sunflower cooking oil increased to more than 27 thousand tons. After the reconstruction, the vegetable oil was produced with modern, mechanized, closed-system technology, in excellent quality. Independent quality inspections consistently qualified the product of the Győr factory as impeccable, and the occasional defects were not related to the product, but to the shortcomings of the bottles, caps and labels.

Szolnok County Newspaper, 1985. No. 234. October 5. p. 1.

Despite this, the change of regime called into question the operation and long-term survival of the Győr plant. Due to the crisis, domestic purchasing power and consumption fell drastically, an increasing part of which was taken up by foreign products arriving due to liberalization and market opening. In Győr, the aim was to stop the decline in production and the number of employees by producing biodiesel. Biodiesel suitable for engine propulsion was made from rapeseed. The environmentally friendly fuel was tested, among others, on the Ikarus bus of Kisalföldi Volán Rt. The experiments promised encouraging results, but the cost of producing biodiesel exceeded the price of traditional fuels, so the idea of making the factory profitable by mass producing a new type of fuel that was less polluting to the environment failed.

Békés County Newspaper, 1992. No. 261. November 5. p. 12.

During the privatization following the change of regime, the Győr Vegetable Oil Factory (along with two other factories) became the property of the Italian Cereol in 1992, which stopped production in its Győr and Nyírbátor factories in 2000. Of the 6 factories of the Vegetable Oil Industry and Detergent Manufacturing Company, the new owner closed five (including the one in Győr) in the few years following privatization, meaning that just as in 1930, the foreign investor bought a market.

There were many complaints from the public against the operation of the plant, which pollutes the environment and has a slightly smelly smell. The relocation of the oil factory, which was surrounded by residential buildings, has been raised more or less frequently throughout its 150-year history. The privatization was followed by a 10-year lawsuit, which was initiated by the party that lost the privatization. The lawsuit did not change the 1992 decision. The foreign owner sold the land of the oil factory in Győr, where the factory building was demolished, two of its chimneys were blown up, and the area has since been built up with residential buildings.

The explosion of one of the chimneys of the destroyed factory. July 22, 2016.

Source: https://24.hu/belfold/2016/07/22/felrobbantotkat-a-gyori-olajgyar-kemenyet-video/

The compilation was based on the study of Dr. János Honvári.

Continue to the detailed study

See also: Éva Némáné Kovács: The history of the Adolf Kohn and Partners Oil Factory in Győr from its foundation to 1910. In. Győri Szalon, City History Puzzle, Part 103.

Source: https://www.gyoriszalon.hu/news/10874/61/

| INTERESTING FACTS |

|

Why have many foreign family businesses established factories in Győrsziget?

Map of the Free Royal City of Győr, 1939. Detail Source: https://maps.hungaricana.hu/hu/HTITerkeptar/35291/?list=eyJxdWVyeSI6ICJHeVx1MDE1MXIgdlx1MDBlMXJvcyJ9

The factories in Győr that mushroomed in the second half of the 19th century, processing agricultural raw products or satisfying direct consumer needs, were generally established as individual, family companies and only changed to the form of a joint-stock company at the turn of the century. The factory founders, who were typically foreigners (residents of Germany, Austria, Bohemia and Moravia), were mostly Jews, who were not allowed to move to cities due to the discriminatory measures imposed on them. Therefore, until their full equality following the Compromise, the Jewish founders settled in Győrsziget, which was still an independent village at the time, separated from Győr only by the narrow Rábca River, where, based on a charter obtained from the village landlord, the Bishop of Győr, they were relatively free to practice their language and religion, send their children to school and run their businesses. Most of the entrepreneurs who settled here found a home in Győr after a while, acquired citizenship, many of them became the most wealthy members of the local society, entered the county and city governments by virile right, became leading officials and managers of local financial, commercial and economic companies, and industrial enterprises. The ruler recognized their long and successful work with honorary titles (royal councilor, real inner and privy councilor). |

||

|

Did you know who first advocated for the relocation of the factory to the outskirts of the city? Between the two world wars, Dr. Lajos Petz, the chief physician, was the main proponent of relocating a factory that was detrimental to both health and urban development to somewhere on the outskirts of the city. According to the factory's historian, this solution would have been favorable in many ways, primarily mentioning the easy expansion opportunity. He also refers to the fact that the city would have supported the relocation with many discounts. However, there is no mention of who would have financed the huge cost of building the new factory site or the production value lost during the construction period. (Berecz Dezső 37.) The relocation of the Győri Szeszgyár és Finomító Rt., which was completely surrounded by residential buildings, was also raised several times, which the factory owners would have accepted if the city had taken on the associated costs, estimated at around 4 billion HUF.

Dr. Felpéczi Petz Lajos Aladár Petz: The past and present of the Holy Trinity Public Hospital of the Free Royal City of Győr, 1749-1928. Győr, 1929. p. 205. Source: https://edok.gyorikonyvtar.hu/book/-/record/33886;jsessionid=29E9E71B505874F875262101EDEDC575

Did you know that the oil factory had a “Raisin”?

All this is revealed in the article “Raisins” by Zsolt Takács of the Győr Oil Factory, issue 1007, on the website www.iho.hu. "Most of the time it could be observed under the silos of the Győr oil refinery, on the loading tracks, while other times the M28-1007 Mazsola would clatter up and down on the truncated track of Híd Street, and it currently spends its peaceful days on the storage tracks behind the Győr heating plant."

Zsolt Takács's recording "We could still see the 1007 moving a few years ago, mainly on the industrial tracks of the Újváros district. However, today most of the tracks have been taken away after the demolition of the oil refinery."

Zsolt Takács's recording

“The Hungarian Wagon and Machine Factory in Győr started producing the M28s in 1955” The article can be read in detail here: http://iho.hu/hir/az-gyori-olajgyar-1007-es-mazsolaja-120408 |

|

Name variations: Imperial Royal Decree Győrsziget Oil Factory 1851 – Adolf Kohn and Co. 1854 – Adolf Kohn's descendants m. royal charter Győrsziget Oil Factory 1874 – Adolf Kohn and Co. Oil Factory 1892 – Adolf Kohn and Co.'s Győrsziget Steam Oil Factory – Oil Works Co., Ltd. Adolf Kohn and Partners Győr industrial plant 1910 – Unilever 1928 – Hutter and Lever RT 1930 – 1949 independent company 1950 – Győr Vegetable Oil Factory of the Vegetable Oil Industry and Detergent Manufacturing (National) Company 1964 – Cereol Győr Vegetable Oil Factory 1992 – 2000 |

||

| LITERATURE |

- 1908? Győr County. Edited by Borovszky Samu. Budapest. 464 pages. Counties and cities of Hungary series.

- 1971. Győr factories and companies. Historical summaries. [SI], [ sn] Manuscript. 254 pages.

- 1975. Dezső Berecz: History of the Győr Vegetable Oil Factory of the Vegetable Oil Industry and Detergent Manufacturing Company. Budapest. 111 pages.

Related gallery

Back to the previous page!