Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Hungarian Waggon and Machine Factory Ltd.

| Adress of the memorial, route planning | ||

| What can we see at the memorial? | ||

| Brief overview | ||

| Detailed Company History | ||

| Facts | ||

| Literature, references | ||

| Related gallery | ||

| Next station of the circle tour I |

| ADRESS OF THE MEMORIAL, ROUTE PLANNING |

Győr, Budai Street 1. (parked area next to the town centre building of Árkád)

| WHAT CAN WE SEE AT THE MEMORIAL? |

The memorial is located in a landscaped area next to the building of the former wagon factory (Budai út 1.), the park next to the building of the Árkád shopping centre.

Only the most significant industrial company of Győr is referred to the industrial history monument preserved in the vicinity of the memorial, the former “spurrant” and the cube-shaped shelter behind the back of the distillery, recognizable by the large Rába logo.

Street view:

-

Pictures from today:

The headquarters of the estate (2018)

In the foreground the buildings of the distillery, the residential buildings on the banks of the Danube were built in the background on the site of the former factory.

Aerial photo: Zsolt Andorka

Breakdown of the office buildings of Rába Hungarian Wagon and Machine Factory (February 2004)

Photo by Zsolt Andorka

The dust-smashed remains of the demolished buildings, in the background the concrete cube of the wagon factory shelter,

top with the air observation post. (November 2004)

Photo by Zsolt Andorka

A picture from the past:

| BRIEF OVERVIEW |

|

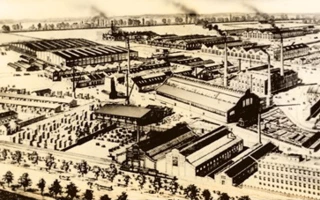

The most important manufacturing company of Győr in the 20th century, the Hungarian Waggon and Machine Factory Ltd. was founded by Austrian contractors on 28 December 1896. In addition to the production of iron structures, the main profile of the factory has become the production of railway and road vehicles. The Great Depression has brought the factory to the brink of bankruptcy. Due to the preparations for the war and then the entry into the war, the wagon factory became one of the largest military industrial plants in the country. Most of the production capacity was destroyed by the bombings of 1944. The factory was nationalized in 1946. In addition to the production of railway wagons, at the end of the 1950s they were engaged in the production of railway diesel engines, locomotives and trains. From the mid-1960s, road vehicle engines and rear bridges were converted to large-scale production. Their main outlets collapsed after the change of regime, so they gave up their central site and continue the production of road vehicle main units and vehicles at the airport. |

| DETAILED COMPANY HISTORY |

The most important mechanical engineering company in the history of Győr, the Hungarian Waggon and Machine Factory Ltd. was founded on 28 December 1896. 88% of the shares of the company, set up with a capital of HUF 500,000, were registered by the members of the Lederer family, which is the leading factor in the manufacturing companies of the Austro-Hungarian Monarchy.

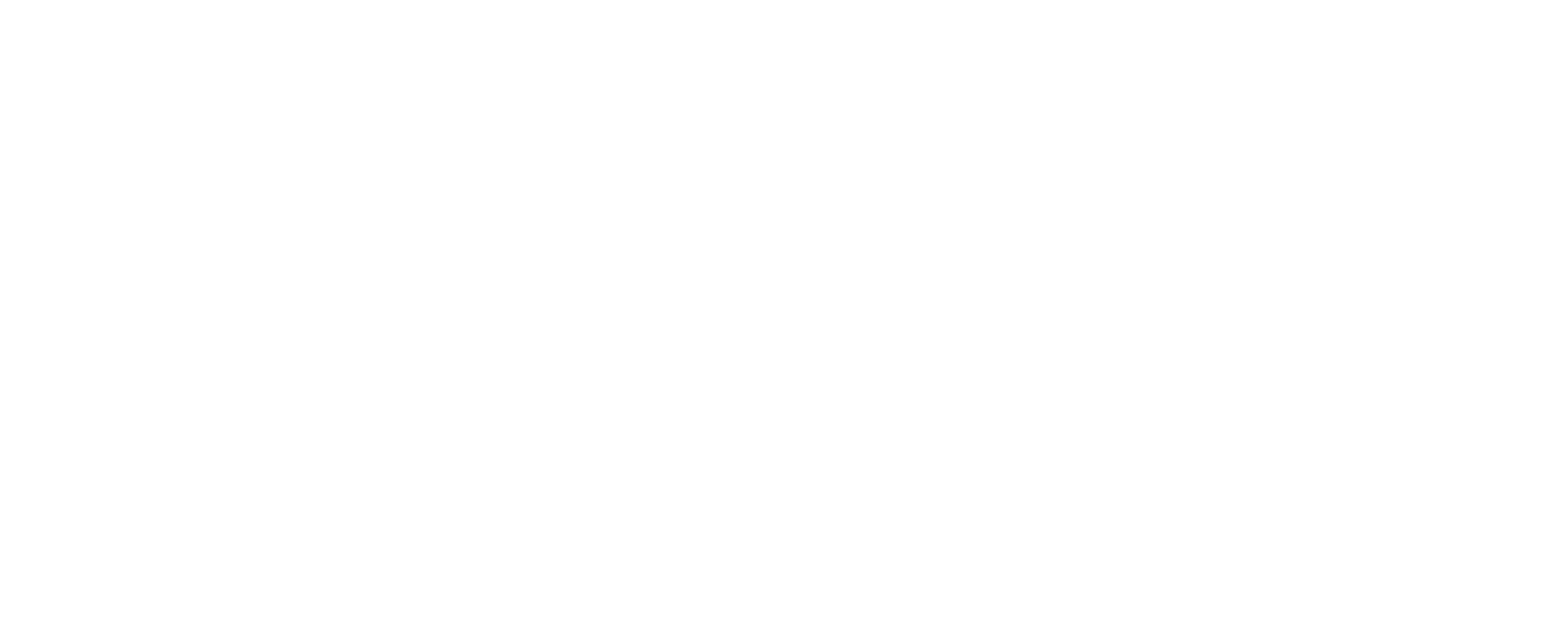

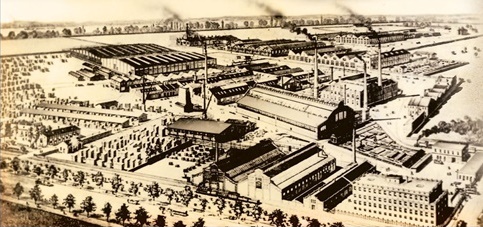

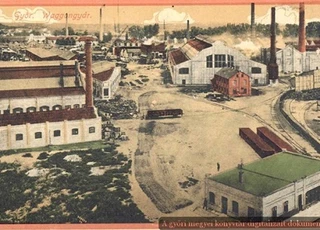

Category: 1910s

Source: http://edok.gyorikonyvtar.hu

For a few years after the establishment of the factory, only rail freight wagons, tankers, flatbed wagons and transport wagons with a simpler structure were produced in Győr. Within a short time, the two main production profiles of the wagon factory, the railway rolling stock and the production of road vehicles were developed. The two basic production profiles have developed in parallel, albeit not at the same pace, since the factory was established, until the end of the wagon production. Just three years after the formation of the company, the idea of the car production was raised at the meeting of the board of directors, and in the early 1900s the first small – essentially custom-manufactured chassis for the Austrian Spitz cars were completed, then postal parcel carriers using János Csonka’s patent, and from 1907 onwards, passenger and vans were licensed under an Austro-Daimler license.

The types of contemporary products can be read in the advertising text

Source: http://edok.gyorikonyvtar.hu/? docId?29616

Before the outbreak of World War I, the license of the Praha car factory was purchased, and 500 trucks and 250 Rába Grand cars were built in Győr until 1928. Buses and engines were also manufactured on the basis of a Praha license. Thus, there is a long tradition in the Wagon Factory to introduce new products by purchasing and adapting the production process.

Bus made according to Praha-license, Rába Museum Győr.

Photo by Zsolt Andorka

During World War I, the Wagon Factory (as a first-class military plant) was forced to cease civilian production, the cars already produced were used for military purposes, and the factory was working on military orders from then on.

After the fall of the Hungarian Soviet Republic, the Romanian army, which occupied Győr for nearly a month, also took furnishings from the Wagon Factory.

In 1927, the Krupp bought the right to manufacture trucks and buses from Austro-Fiat. The former unique, workshop-system production was replaced by the industrial, modern car production. Gray and steel foundry, forging and cutting plants, heat treatment and material testing laboratories were established to meet the technical standards of the age.

The first Rába-Krupp truck was ordered by the Telephone Factory, which was completed in the spring of 1929. Special vehicles were also manufactured to order, e.g. sprinklers and asphalt washers, snow sweepers and excavators, ladder fire trucks, tank cars, etc.

Rába-Krupp truck 1934. It was the property of the Győr Textile Works

Source: http://www.fortepan.hu/? img?71044

Due to the nature of its products, the State and among you were the number one customers of the Wagon Factory. The vast majority of freight, passenger and special wagons were sold domestically and abroad to state railway companies, but the situation was similar in the field of road vehicles, as the vast majority of road transport vehicles (buses, trucks) were also owned by public utility plants and factories between the two world wars. With the exception of the United States of America, the passenger car was considered to be the cause of a dwarf minority, and not only Hungary, but also the majority of Western European countries that are much more developed than us, were far from becoming an everyday usage object for the car. Certainly, insignificant domestic demand was the reason why the Wagon Factory, which produced passenger cars manufactured at the dawn of road vehicle production, never again started producing them since the 1920s.

Alpha "sport car" 1913

Source: http://www.kisalfold.hu/blog/kisalfoldi_historiak/a_raba_vagon_es_gepgyar_legendas_gyartmanyai_i/146/2786/

In the years of the economic crisis of 1929-33, 22 to 72 units of cars per year, and none of their main products, rail passenger and freight wagons, were produced in 1933, and 60 to 312 wagons per year. During World War I, the Wagon Factory employed between 3 and 4,000 people. In contrast, the average number of workers fell to 465 in 1932 and 224 in 1933.

Source: http://edok.gyorikonyvtar.hu

In 1935-36, based on Rába Austro-Fiat, the most well-known civilian types of vehicles of the Wagon Factory, the Rába Super and Rába Specál trucks and buses, were constructed on the basis of the Rába Austro-Fiat, of which the company produced some 2500 units until 1951.

Until the mid-1930s, the Wagon Factory had installed only petrol engines in its road vehicles, which had been licensed for decades to its own equipment. In 1937, the right to manufacture the four and six-cylinder crude oil engines of the German Maschinenfabrik Augsburg-Nurenberg (MAN) were purchased.

As a result of the war economic activity, the number of employees of the Wagon Factory increased by nearly ten times compared to 1936, by 1944, the value of its properties and assets increased by more than five times, according to the public balance sheet data, almost eight times its production value, and more than 40 times its order volume.

The wagon repülőgépgyártásfactory’s youngest – and if it had had a sufficient run-out – was certainly the automotive industry’s sector, which became the most dynamically developing and sales business of the factory during the war. In Győr, aircraft were first repaired, and then the production of the Sólyom and Focke-Wulf two-engine training fighter aircraft began. The first Messerschmitt Bf-109 fighter jet produced in Győr was released into the air in the spring of 1943. The largest German fighter aircraft, produced in the largest number of aircraft produced in the Wagon Factory, was manufactured in Gőr, the fuselage of the aircraft, the so-called dragon, and the assembly and testing took place here.

WM-21 Sólyom aircraft manufactured in Győr

Source: http://www.gyor-per.hu/ii-vilaghaboru.html? Starting with 20

During the war, 18 major and 17 minor bombings hit the city. The first and most destructive was the 13th of April 1944, when the 163 British and American B-17 bombers attacking Győr were tasked with destroying the Győri Vagon and Machine Factory, the airport beyond the Industrial Canal and the planes with a multitude of destructive and incendiary bombs.

The Anglo-Saxon Air Bombing of the factory on 13 April 1944 put an end to the production of military combat vehicles, destroying about 60-70% of the Wagonwork buildings and equipment and severely damaging airport equipment.

2 July 1944 Wagon factory after bombing

Source: http://kony.network.hu/kepek/regi_gyori_kepek/vagongyar_bombazasa_1944_jul_2-001

Like the other military plants of the country – with the agreement of the Germans – some of the production equipment of the Győr Wagon Factory was relocated to the surrounding villages. The planes taken from the steel casting were returned from Sárvár and put into operation, because the Győr-based factory, which was placed under the Soviet military headquarters, repaired the vehicles of the occupying army. The goods deported to the West were never returned to the factory.

Despite the heavy losses, the work started quickly, the factory played a significant role in the restoration of the city, and later the detonated bridges of the area, in which it was supported by the occupying army, as the movement of the Soviet army without road and rail bridges were difficult.

On 1 December 1946, the Hungarian Wagon and Machine Factory of Győr was also managed by the state. In the summer of 1947, the Győr-based plant of MÁVAG was merged with the Wagon Factory.

Győr, July 1945. Repairers repair a truck at the service of the Győr Wagon Factory Rába.

The exact date of recording is unknown.

MTI Photo/MAFIRT

Owner: MTI Zrt. Photo archive

Source: https://archivum.mtva.hu/photobank/item/MTI-FOTO-eUxmTdrUhHhEcUFLOXR0bXN1aJJJZz09

From 1949 to 1950 in Győr, the end of the 1960s, completed vehicles were not produced, instead the production of main units (lifting and rear axles, steering gears, gearboxes) was used for the assembly factories in units separated from the parent factory, separated, and attached to other large companies. Győr’s most important task was to produce rail freight and passenger wagons, the vast majority of which were exported to reparation until January 1953, and subsequently to Romania, Yugoslavia and later to some developing countries within the framework of bilateral exchange agreements. He has many decades of experience in the production of the factory, bridge and steel structures.

The modernization of the obsolete structure of the Hungarian industry was on the agenda in the second half of the 1950s. Within the automotive industry, there was high hope for dieselation of the railways. The Győr Wagon Factory was commissioned to produce smaller engines, small locomotives and light motor cars.

Győr, 4 October 1957 The Bmot type train in the courtyard of the Hungarian Wagon and Machine Factory.

Photo by Róbert Horling

Owner: MTI Zrt. Photo archive

Source: https://archivum.mtva.hu/photobank/item/MTI-FOTO-ZlRjbTBVa3dpOXRCcU9zTmN1Tk1Ddz09

Eda Horváth was appointed CEO of the wagon factory in the spring of 1963, while at the same time retaining the position of director of the Győr Machine Tool Machinery Factory. On January 1, 1964, Wilhelm Pieck Combined the Győr Machine Tool Factory and the wagon factory under the name of Wilhelm Pieck Automotive Works.

Ede Horváth thoroughly reorganized the wagon factory, centralized the control, merge departments and organized new departments, and did not hesitate to release people in the socialist system in an unusual way if necessary.

G

Győr, 3 November 1969. The prototypes of the special trucks equipped with the Rába-Mann Diesel engine have been completed at the Győr Wagon Factory.

Photo by János Hadas

Owner: MTI Zrt. Photo archive

Source: https://archivum.mtva.hu/photobank/item/MTI-FOTO-K3dxZEl3VGtVGtVhYVhNNkp3QXZTdz09

In the mid-1960s, the factory giant switched to the production of high-performance road diesel engines and the production of self-designed large-scale chassis as part of the VCO automotive industry program of the COMECON in the framework of the VPP plant in the middle of the 1960s, and gradually abandoned the production of conventional railway wagons. Various trucks, tractors and agricultural machinery were also produced.

A multi-billion-dollar investment program has been launched, under which the MAN-Renault-Ferrostatal consortium in the core factory has been equipped with a 13,000 200-leith Avenue diesel engine production plant by 1969. The engine factory of Rába started to produce a globally modern-standard engine with a high production technology standard, one whose parameters far exceeded the technical parameters of the Csepel engines produced so far, but also the technical parameters of the engines produced in the whole eastern camp.

At the former airport, the 28,000, 67,000 square meters of engines were built, and the vacant 114,000-square-metre halls for the period of the regime change were built. In addition to the halls, additional facilities (caste, forging and tooling plant, office buildings, etc.) were also built at the airport. The local production of the main units of the trucks (engine, front and rear bridges) made it possible for Rába to start producing heavy tractors from 1968, and a few years later, co-operating with the American Steiger tractor company Steiger, and a few years later, co-operating heavy tractors (Rába-Steiger, Rába 180).

Rába 180

Source: https://images.search.yahoo.com

In the whole socialist era, the main market for RÁBA’s products was the former socialist countries. However, in the field of chassis production, Rába reached such a technical-technical level that from the second half of the 1970s this product managed to break into the market of the Western (or overseas) countries as well.

The last major development of the Wagon Factory before the change of regime was the establishment of a test track called the Rába-ring in Ecs. The former is ready, the latter is no longer.

Rába ring detail, Écs

Source: http://ecs.network.hu/kepek_falunkrol/raba_ring_egy_kis_resze

In 1990, the collapse of the Eastern markets was the most important factor that almost buried the factory giant. The accumulated loss approached the HUF 9 billion by 1991, so this year it was placed under the supervision of the state administration and Barnabas Zalán was appointed as the head of the Rába. The state crisis management project proved to be successful, and the company closed the year 1992 with a modest profit – at the cost of severe self-mutilation and the transformation of individual businesses into self-accounting units. Rába was transformed from a state-owned company to a public limited company in 1992, which was listed on the stock exchange in 1997.

Since 1999, the company has organized its main activities in external companies and has been operating as a holding company (Rába Automotive Holding Plc.) since then. The 114,000-square-metre giant hall, which remained at the airport, was purchased by Audi in 1993 and the Szentgotthárd site by General Motors, and the other rural factories were separated from the parent factory.

In 2000, they decided to sell the central site and move to the former airport. They abandoned the loss-making bus production and then sold the engine factory that has been bankrupt since then. Most of the old buildings were demolished, and the Engel Group planned to build 6,000 apartments as a brownfield investment, but the international financial crisis of 2008 intervened, the company abandoned the construction after the construction of the few hundred apartments started. Today, in the former area of the central factory unit of the Rába, the Árkád shopping centre is in operation, the residents moved into the completed apartments, the remaining residential buildings were completed. Some of the area of the mother factory is still owned by the holding company, and its fate is still unknown.

The compilation is Dr. It was based on the study of János Honvári.

| FACTS |

|

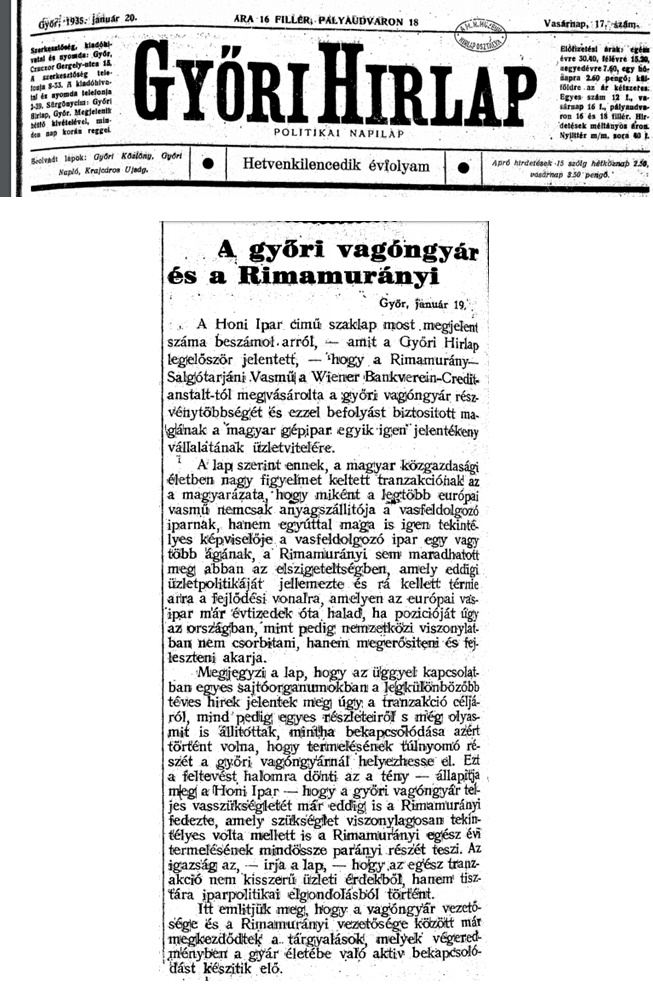

According to the daily newspapers, the first passenger car in Győr is dr. Lajos Petz was the head of the hospital, who appeared on the roads of the city on 3 July 1910 with a composition of 5.5 hp, which caused a great deal of attention. At the beginning of the 1920s, the number of motor vehicles in the city increased very slowly. Győri Hírlap, 4 April 1926. (p. 20) |

|

The most famous military vehicle of the factory, the Botond swarming off-road vehicle was designed under the direction of Dezső Winkler, the factory’s chief structural guard, and it was produced in large series until the factory’s bombing on 13 April 1944. In 1939/40, the production of the Botons made up of about 11 million pengos from the car class’s turnover. Botond swarm vehicle, Rába Museum Győr |

|

Name variations: Hungarian Waggon and Machine Factory Ltd. Hungarian Wagon and Machine Factory Wilhelm Pieck Wagon and Machine Factory Rába Hungarian Wagon and Machine Factory Rába Automotive Holding Plc. |

| LITERATURE, REFERENCES |

- 2014. Germuska Pál, Honvári János: The History of Road Vehicle Manufacturing in Győr from 1945 to 1990. Yeah. The drivers of Győr’s development. Monographs of the research of the automotive industry district of Győr as the new direction and tool of regional development 1. Győr, Palatia Printing House. 11-111.

- 2014. István Áldozó: The Rába Hungarian Wagon and Machine Factory in the decade after the regime change. Yeah. The drivers of Győr’s development. Monographs of the research of the automotive industry district of Győr as the new direction and tool of regional development 1. Győr, Palatia Printing House. 112-139.old.

- 1996. Rába 1896-1996. 5 db. He is published by the Information Organization of the Rába Hungarian Wagon and Machine Factory, Győr. Publications of the Rába Centenary Demonstration Centre.

- 1996. Rába 1896-1996. He is published by the Information Organization of the Rába Hungarian Wagon and Machine Factory, Győr.

- 1972. Tabiczky Zoltánné: The History of the Hungarian Wagon and Machine Factory in 1896-1945. One or two. knitting. Hungarian Wagon and Machine Factory, Győr.

- 1956. Géza Gárdonyi, Jr.: The history of the Győri Wilhelm Pieck Wagon and Machine Factory, 1896-1956. Győr-Sopron county Printing House, Győr.

- Rába Automotive Holding Nyrt. http://www.raba.hu/cegtortenet.html

- Győr-Pér airport http://www.gyor-per.hu/a-vagongyar-repulotere-gyor-hecsepusztan.html? Starting with 20

- 120 years of Rába http://www.raba.hu/www.raba.hu/doctar/120/Raba_tortenet.pdf

Related gallery

Back to the previous page!