Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Hungarian Lace Factory Ltd.

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Related gallery |

| ADDRESS OF THE MEMORIAL SITE, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL |

The former Gardénia Lace Curtain Factory is now home to a shopping mall called Dunacenter. The 6,500 m² center, located next to Highway 1, near the Vienna-Budapest highway exit, was opened in October 2009.

Source: https://dunacenter.com/about us/

Street view:

| BRIEF OVERVIEW |

|

The first Venetian lace factory in Hungary was founded in Győr by the English lace manufacturer Frank Tatham in 1911. In 1913, the Hungarian Lace Factory Co. operated at full capacity: 7 weaving machines and 50 people. The range of its products was constantly expanding: after the initial production of Venetian lace and lace fabrics, in 1923 the First Hungarian Lace Curtain Factory Co. started making lace curtains, and later carpet production and tulle weaving. During the war years, they produced bandage materials, and after nationalization, onion and potato sacks were woven in the Gardénia Lace Curtain Factory. From the 1960s, they began producing synthetic curtains, and later expanded their range with jacquard products. The company is credited with developing the soil-absorbing finishing process (Soilreease). The leading company in the domestic lace and curtain manufacturing industry exported to more than thirty countries around the world, and its number of employees exceeded 800 in the 1990s. After successful years, the textile industry downturn also affected the factory. In 2008, its liquidation began. On the 100th anniversary of the lace curtain factory's founding, in 2011, the Gardénia brand name was purchased by Rovitex Homedeco Group. |

| DETAILED COMPANY HISTORY |

In his submission to the Hungarian Minister of Trade on 4 March 1910, Nottingham lace manufacturer Frank Tatham requested state benefits and state aid for the lace factory to be established in Győr, as provided for in the industrial support laws. The factory to be established was planned to have a weaving plant with 10 English-made lace looms, as well as a bleaching and finishing plant. The city of Győr – under certain conditions – provided the English entrepreneur with nearly 12 thousand m² of free land and a 15-year exemption from local taxes, but it was stipulated that after the permit was granted, Frank Tatham Limited Rt. was obliged to build and start up the factory within one year.

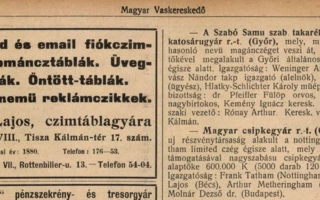

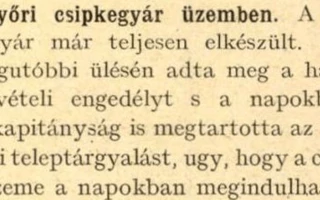

Hungarian Iron Merchant, June 18, 1911

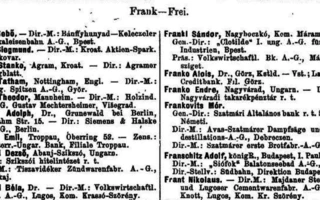

In the first volume of the Compass 1912 Finanzielles Jahrbuch, published in Vienna in 1911, Frank Tathem's name is already listed as the director of Győr.

Source: https://portal.zedhia.at/

The Hungarian Lace Factory Co. Ltd. plant was completed by the summer of 1912, and production reached full capacity in 1913. On the ground floor of the two-story building, the lace factory started with 7 second-hand weaving machines, contrary to the contract. The lace was adjusted, cut and darned on the first floor, and dried on the second. The dyeing and finishing plant, combined with the boiler house, formed the other facility of the factory.

Honi Ipar, June 1913. No. 11. p. 18.

The factory employed 50 workers, although the joint-stock company had agreed to employ 50-60 men and 60-80 women. After the outbreak of World War I, the first floor of the main building was used as military accommodation, and later the wounded were housed here. Production was hampered by a shortage of raw materials, and they only produced in one shift. Their products met wartime needs: they wove bandage materials and produced materials for face veils from caterpillar silk. The factory went bankrupt and the factory was closed in 1917. The English owners left in 1919 and sold the company.

In 1922, an Austrian entrepreneur bought the factory and restarted it under the name Győri Csipkegyár Rt. At that time, Venetian lace and lace fabric were produced. In 1923, curtain production began with the purchase of two curtain machines, which also appeared in the company's name: Első Magyar Csipkefüggönygyár Rt. Further developments brought new results. The main site of the Első Magyar Egyesült Csipkefüggöny, Csipke és Hímzőgyár Rt. was in Budapest, with a branch office in Győr. Carpet and towel production also began in Győr. After a successful period, the company went bankrupt again during the Great Depression, and only in 1935 did the new owner manage to restart the business under a new name – Gardénia Csipkefüggöny és Szövőgyár Rt. In the meantime, in accordance with market demands, the embroidery machines were shut down and tulle production took precedence. In the second half of the 1930s, production in the factory was running at full capacity, with the number of employees reaching 120.

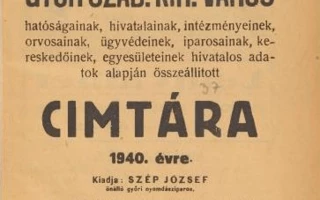

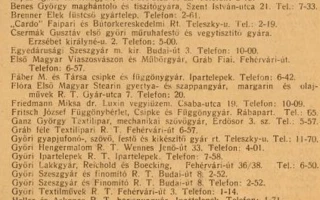

In the 1940 directory, the Győr factory of Gardénia Lace Curtain and Weaving Factory Rt., registered in Budapest,

Fritsch József is listed as Curtain Rental, Lace and Curtain Factory.

Source: http://edok.gyorikonyvtar.hu/?docId=52525

The rapid growth was ended by the outbreak of World War II. Lace and curtains were considered luxury products, and the procurement of raw materials was very difficult at that time. In 1944, only bandages were produced. During the war, the factory chimney was hit, the buildings were damaged, and some of the machines burned down.

Recording: László Mönich-János Csák: Gardénia Lace Curtain Factory. 1955.

Source: https://filmhiradokonline.hu/watch.php?id=11922

After nationalization, the company operated under the name Gardénia Lace Curtain Factory, where for years they wove onion and potato sacks, which were exported. Curtain production was restarted in 1950. In 1951, the Gardénia plant and machinery were expanded by merging several companies. It was only in the 1960s that the factory began to slowly develop. Market interest increasingly turned towards synthetic products.

While the lace was made from cotton in the Győr factory, the Budapest company had already started producing synthetic products.

Bácskiskum County People's Newspaper, November 9, 1955, No. 263.

Southern Hungary, November 11, 1960, No. 266, p. 1.

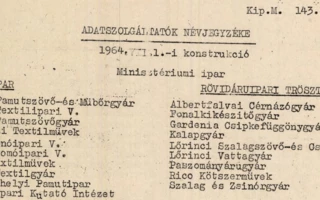

National Economy Plan for 1965. Ministry of Light Industry Plan for 1965. MNL-OL-XIX-A-83-b 3470/1964.

The year 1968 brought significant changes in the life of the Győr factory. The Short-Term Goods Industry Trust, to which Gardénia belonged, ceased to exist in December of the previous year. After initial difficulties, the independent company began the reconstruction process. Thanks to the investments, synthetic curtain production began.

Imréné Földes took over the factory in 1976, and under her leadership the reconstruction of the plant began, as a result of which the production value, profit and capital exports increased dramatically. Taking into account market demands and modernizing the production structure, the production of jacquard curtains began. From 1978, the company began selling its curtains on the capital market, and domestic customers also had access to products that satisfied Western European demands. The factory's specialists also appeared on the market with their own designed and developed products. The Soilrelease finishing process was developed and first applied to curtains by the factory's technologists. The curtains retain their white color for years and are easy to wash.

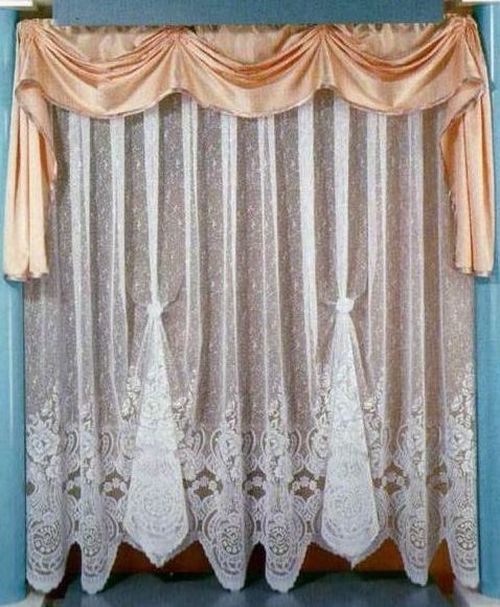

Detail of a jacquard curtain. It creates the effect of a hand-crocheted curtain, and delicate and detailed patterns can be created using the technology.

In addition to the triumph of jacquard curtains, the production of traditional curtains was also modernized, with the appearance of rustic-looking structured (grid-weave) curtains, which were characterized by simple lines. Another type of traditional product - in addition to warp-knit curtains - was the patterned fabric base.

In 1984, Gardénia served 109 customers from 22 countries.

View of the factory from the Peace Bridge, 1982.

Source: Old Győr https://www.facebook.com/regigyor/photos/a.221891967824414/2333275566686033/?type=1&theater

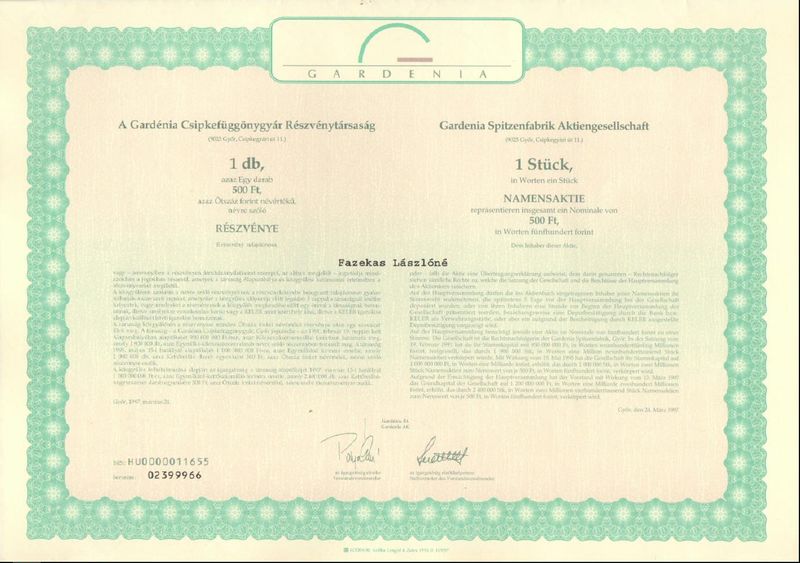

By the 1980s, Gardénia had become the leading company in Hungarian curtain and lace production, and its production profile was expanded to include embroidered products based on a cooperation agreement with a Jerusalem company. In 1990, Dr. Zoltánné Polyák, Gardénia's chief accountant and then deputy economic director, was appointed as acting director, succeeding Imréné Földes, who was retiring, at the helm of the factory. Gardénia was re-formed into a joint-stock company on February 19, 1991. Based on the authorization of the owners, Zoltánné Polyák served as the president and CEO of the joint-stock company from February 15, 1991 to October 1, 1999.

Machine for producing structured curtains. A structured curtain is a simple, unpatterned curtain made with mesh weaving.

The factory came under majority foreign ownership in 1991, with 91% of the shares being purchased by Austrian stockbroker Peter Zelnik. The joint-stock company achieved significant economic and professional success in the first years following the transformation and privatization. 65-70% of their products were exported to 35 countries. They opened a three-story store on Baross Street in Győr. Their world-class products were recognized with numerous domestic and international honors and prizes.

Petőfi Népe, June 11, 1992, No. 137.

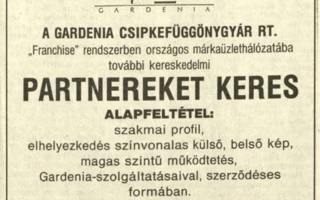

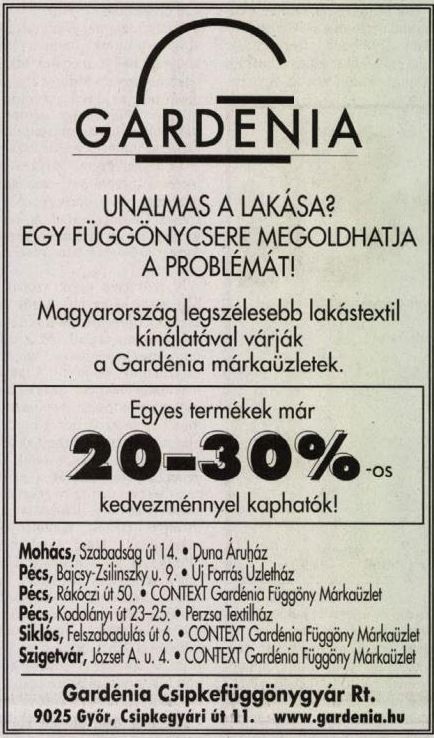

The mid-1990s were still marked by prosperity. They built up the Gardénia brand store network operating in a franchise system, which already had 80 members in 1995. With a 70% market share in Hungary, their leading position in the field of curtain production and sales was unquestionable. The company was listed on the stock exchange in 1997.

Window-ready, ready-made curtainsSource: Success Calendar, page 40.

The first signs of the crisis appeared in 1997. The demand for knitted curtains in the domestic market fell significantly, while raw material prices rose. The parent company founded nearly a dozen subsidiaries at home and abroad to sell its products. Gardénia Rt. and Gardénia Textilhandels GmbH. In 1997, it employed 831 people. The company paid great attention to retaining its customers and exploring new ones. But they could not prepare for the fastest change, the change in customer needs, and the emergence of new fashion waves.

New Word, September 9, 1997, p. 6.

In 1998, they opened their C+C store and established a self-service shop on the premises of the factory. Years of losses followed. In 1999, Dr. Zoltánné Polyák was replaced as CEO by Péter Naményi, a mechanical engineer and textile technician. The new management developed a reorganization program to reduce the losses of the group.

Advertisement in the Dunántúli Napló, December 9, 1999 issue, page 8.

The economic difficulties, which were considered temporary, were attempted to be alleviated by partially shutting down production in July 2001. In 2002, the company laid off 250 of its 322 employees. In December 2004, the company's managers purchased the nearly two thousand square meter plot of land in its neighborhood from MÁV. However, this transaction was no longer about expanding or even preserving the original profile, but about expanding the factory site and utilizing it for other purposes. At the company's request, the city reclassified the property, which was listed as an industrial area in the urban planning plan, as a prime shopping center area and provided a 60% development opportunity instead of the average 40% development opportunity. A shopping center called Dunacenter was established at the Győr site.

Floral Jacquard Curtain

http://www.gardenia.hu/hun/Termekek/31113-viragmintas-jacquard-vitrazs-2

After the sale of the premises, the company, whose staff was becoming increasingly slim, moved to a rented building in the Győr International Industrial Park. The nearly 100 remaining employees no longer produced, but were engaged in the packaging of ready-made products in stock. In the summer of 2008, the company began its liquidation without a legal successor. Of the 800 employees employed in the early 1990s, 20 employees remained at the start of the liquidation. In 2011, Norbert Romeisz, owner of Rovitex Homedeco Group, purchased the Gardénia Csipkefüggönygyár brand name and the rights attached to it from the company's liquidator for a few tens of million forints. The new owner needed brand recognition and an extensive, partly live partner store network. He opened five stores in Budapest and more than thirty stores from Celldömölk to Zalaegerszeg.

Source: http://www.gardenia.hu/hun/

The two huge factory halls from the Gardénia buildings were demolished in their old location and erected a few kilometers away, which are being operated by entrepreneurs from Győr as a logistics center. The Dunacenter shopping center was handed over to customers in October 2009.

In the compilation, we also used the study of Mrs. Orbán's Dr. Márta Horváth.

Continue to the detailed study

| INTERESTING FACTS |

|

The Csipkegyári út was named after the factory, which was opened in 1913. It started from Kossuth Lajos út and extended southeast to the embankment of the Budapest-Vienna railway line. On the left side were family houses and the Gardénia Csipkefüggönygyár, and on the right side was the special purpose machine factory. The Gardénia Lace Curtain Factory was listed on the stock exchange in 1997.

Registered share with a nominal value of HUF 500

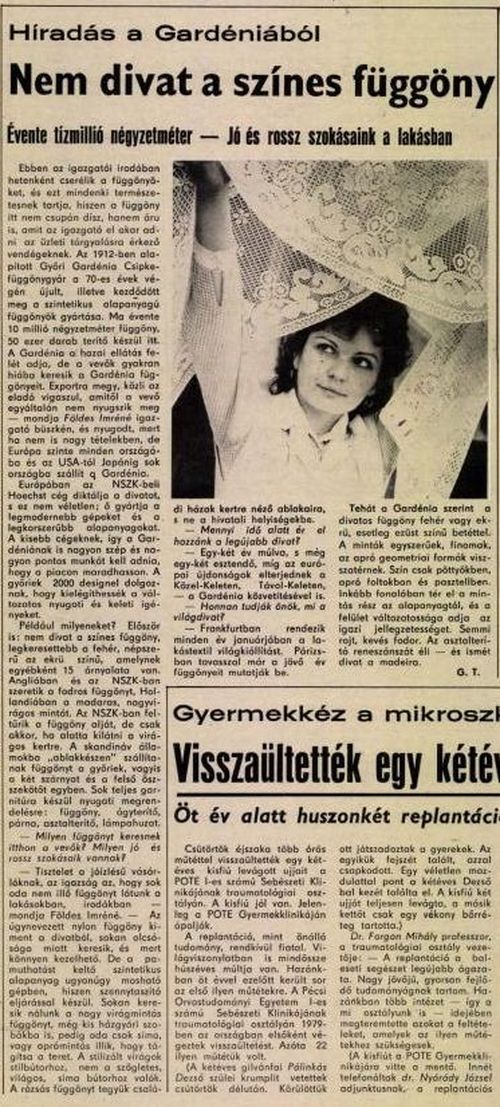

Did you know how quickly curtain manufacturing in Gardenia followed fashion? Read the article published in Dunántúli Napló, issue 112, April 24, 1984.

|

||

|

Name variations: Hungarian Lace Factory Co. Ltd. 1911– Győr Lace Factory Co., Ltd. 1922– First Hungarian Lace Curtain Factory Co., Ltd. 1923– First Hungarian United Lace Curtain, Lace and Embroidery Factory Co. Ltd. 1924– Fritsch József Curtain rental, Lace and Curtain Factory (Győr factory) 1931– Gardénia Lace Curtain and Weaving Factory (registered in Budapest) 1935– Gardenia Curtain Factory 1950– Gardenia Lace Curtain Factory Ltd. 1991– Gardenia Plc. 2006.

|

||

| LITERATURE |

- 1962. István Sajka: 50-year history of the Gardenia Lace Curtain Factory. Budapest. 16 pages.

- 1980. Gardénia Lace Curtain Factory. In. Light industry of Hungary. [Ed. Bárkányi Imre et al.][Bp.], INTERPRESS. 130-134. pp.

- 1987. N. Magyar Tibor, Koloszár Tamás: Gardenia. Győr, 71 pages.

- 1996. Gardénia. In. Győr-Moson-Sopron county success calendar 1996. [Edited and published by Sándor Egri]; [photos by Károly Matusz and the photo archives of the companies]. Szolnok. 34-41. pp.

- 2014. Orbánné Márta Horváth: The transformation of the textile industry in Győr from 1985 to the present. In: From the Hungarian Mechanical Cotton and Woolen Fabric Factory to the Győri Textilművek Részvénytársaság. In. The driving forces of Győr's development. The Győr automotive industry district as a new direction and tool for regional development. Monographs of the research 1. Győr, Palatia Nyomda. 162-165. pp.

Source: http://www.gardenia.hu

Related gallery

Back to the previous page!