Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Heller & Asconas Rt. Hosiery and Glove Factory

| ADRESS OF THE MEMORIAL SITE, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

The former Hungarian Cannon Factory operated in the area bounded by Ipar út – Kandó utca – Ipar-csatorna – Puskás Tivadar út . After the factory closed down, several companies began operating on the plot within the characteristic brick wall fence. One of these is the company known today as Glovita Gloves Co. Ltd.

The memorial plaque is located on the wall of the company's main building at 15 Kandó Street .

There is a reception service at the site, but with prior registration, you can view the old production equipment and the company's current products on display in their showroom on the ground floor.

Street View:

-Glovita Gloves Co., Ltd.

Source: https://commons.wikimedia.org

| BRIEF OVERVIEW |

|

The Győr factory was founded in 1929 by the Vienna-based Heller and Askonas hosiery and glove factory in a building of the Artillery Factory that was dismantled after World War I. Initially, they were engaged in hosiery production, and later they also started glove production on semi-automatic machines. After nationalization in 1952, the production of stockings was discontinued, the company was renamed the Győr Knitted Glove Factory, and significant development was carried out from the middle of the decade. The company's main profile became the production of fashion gloves, glove linings, and multi-purpose work gloves. From 1984, the company, which already had independent export rights, continued to operate under the name Glovita Győri Kötöttkysztyárgyár. Glovita Gloves Zrt., which was re-established as a joint-stock company in 1992 , is the largest glove factory in Central Europe, producing more than ten million pairs of gloves per year, half of which are exported abroad. Today, as one of the best-known glove factories in Europe, they produce high-quality safety gloves for almost all areas of occupational safety, from thin cotton gloves to thick cut- and abrasion-resistant types. On more than 300 modern, new-generation Japanese glove knitting machines, they are able to combine knitted and ready-made technology and produce combined (leather and Nomex, Kevlar fabrics) multifunctional protective gloves. Of the many textile factories in Győr, only a few managed to stay afloat after privatization, Glovita Gloves Co. Ltd. is one of such successful enterprises. |

| DETAILED COMPANY HISTORY |

The Győr plant was founded in 1929 by the Vienna-based Heller and Asconas hosiery and glove factory in one of the buildings of the Artillery Factory that was dismantled after World War I. The company's headquarters was in Chemnitz, Germany, and the machines were also transported to Győr from there. At the beginning, they knitted stockings and employed 40 workers. At the start, they received a ten-year tax break from the state and a fifteen-year tax break from the city. The only condition for this was that 90 out of 100 employees during the development were Hungarian workers. In 1931, the company's profile was expanded to include glove production , which marked the beginning of machine-knitted glove production in Hungary in 1932. After a change of ownership, Heller & Asconas Rt. Hosiery and Glove Factory was transformed into Hellas Rt. in 1940.

News column, Győri Hírlap, March 1, 1935. No. 50. p. 5.

Source: http://edok.gyorikonyvtar.hu/

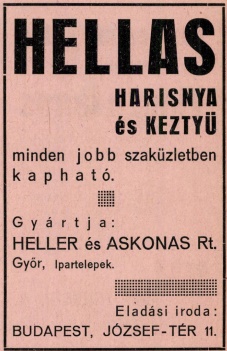

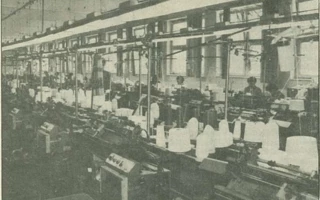

Source: Győri Szemle, 1938. No. 9. p. 196.

In 1941, the share capital was significantly increased. The mayor of Győr, Gyula Späth, called on the factory management to declare that the agreement had been violated, and that there were more foreign specialists in the management than the number allowed in the contract. The factory management quickly responded by informing the mayor that the technical managers in question had returned to their homeland.

After the war, the number of employees from 120 gradually reached 240 as the economy boomed. The joint-stock company was nationalized in 1948 , which meant that they lost the Hellas brand name, which had ensured the market recognition of their products. In 1952, the production of stockings was discontinued in the factory , the company was renamed the Győri Knitted Glove Factory, and serious development was carried out from the middle of the decade.

Their main profile, in addition to fashion gloves and glove linings for leather gloves, remained the production of multi-purpose work gloves.

On November 1, 1963 , based on the state's rural industrialization concept , the company's factory for the production of tailored gloves and sanitary rubber textile products was built and put into operation in Celldömölk . Judo and karate uniforms were also produced here.

Celldömölk factory, 1989

Source: Béla Soós: GLOVITA – living glove. In: Új Kemenesalja, 1989. 1-2. sz. 12. p.

http://cellbibl-digit.cellkabel.hu/ujkem/ujk89.02.pdf

To alleviate employment problems, dynamic development was implemented in the 1970s , which enabled the large-scale production of sophisticated products, allowing them to join the international division of labor in a new way.

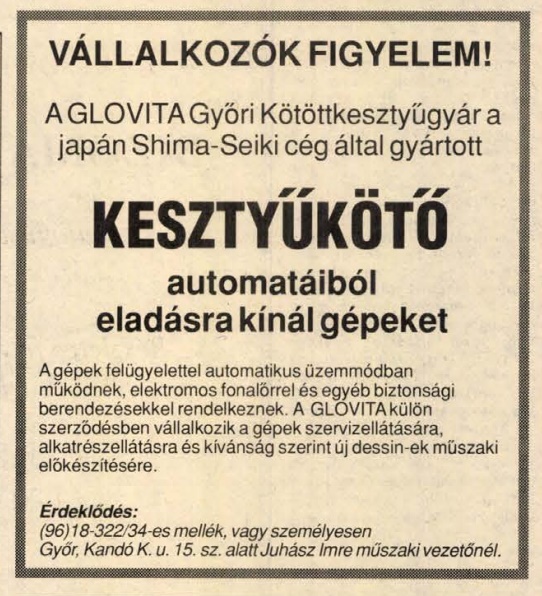

The energy crisis that broke out in 1973 and the rapid increase in the price of raw materials created a new situation in the glove market. The price of leather increased several times, so demand decreased, but at the same time the interest in cheaper knitted gloves increased. Therefore, in 1978, the people of Győr purchased modern, programmable automatic glove-knitting machines from the Japanese manufacturer Shima Seiki . The cheap fashion gloves produced on the new, automatic, cut-to-size knitting machines without cutting or sewing quickly pushed leather gloves, which were less popular due to the increase in the price of raw materials, into the background. The modern machines achieved a 40 percent material saving, and output was tripled in a short time, while the number of employees decreased by nearly four hundred. This created the most modern factory of its kind in Europe. During the change of regime, the old director, József Marton, a certified mechanical engineer, was re-elected.

Card calendar advertising karate clothing for the year 1984

Source: http://f1hungary.fw.hu/kartyanaptar/katalogus.php

Since 1984, the company has had independent export rights under the name Glovita Győri Knitted Glove Factory. As the largest glove factory in Central Europe, it already produced ten million pairs of gloves per year, and exported half of this abroad, primarily to the Scandinavian countries, as well as to France, Germany and the Soviet Union.

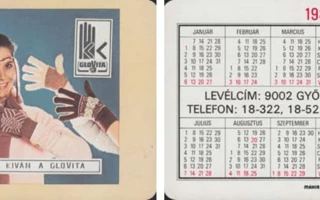

Card calendar advertising products for the year 1985

Source: http://f1hungary.fw.hu/kartyanaptar/katalogus.php

In 1989, the factory celebrated its 60th anniversary with the purchase of 90 new computer-controlled glove knitting machines and various auxiliary machines and the opening of a new 2,700 m2 knitting factory.

The market collapse after the change of regime : the loss of Soviet exports and the bankruptcy of large domestic companies manufacturing for Soviet exports, as well as the overwhelming flood of Chinese dumped goods destroyed a significant part of their foreign and domestic markets.

In the spring of 1991, they sold their new factory and moved their machines back to their old hall in the former artillery depot. The proceeds were used to pay off their debt.

The Celldömölk plant was transformed into an Italian-Hungarian joint venture under the name Glovitalia, and the number of employees here also shrank to a fraction of its previous size.

New Transdanubian Diary, 19. 02.19. 1991. No. 49.

Source: https://library.hungaricana.hu/hu/

On January 1, 1992, the Knitted Glove Factory was transformed into a joint-stock company with a share capital of 248 million forints, with the participation of the Hungarian Foreign Trade Bank, the French Riby SA, the German Seiz GmbH and the City Government of Győr.

The actual privatization was completed in December 1994, when ÁVÜ sold its 75 percent stake to a consortium consisting of the company management and the founding foreign companies. The employees also participated as owners in the company.

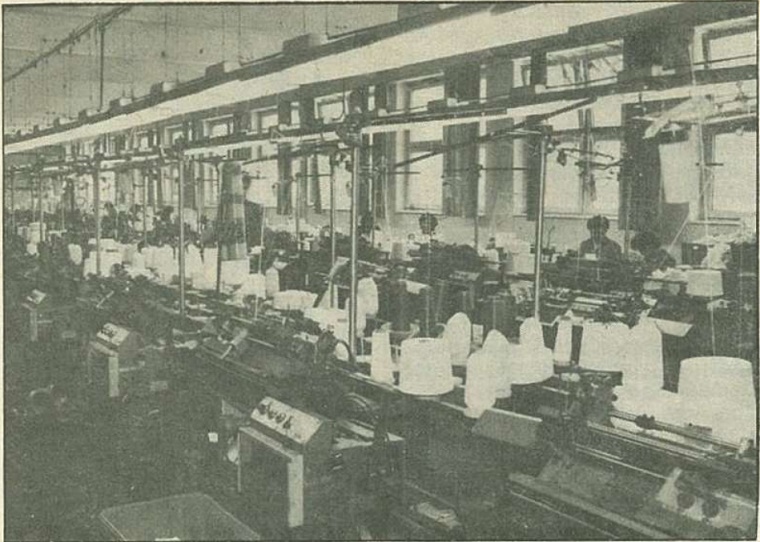

New generation Japanese glove knitting machines

After the difficulties of the transition , new machines were purchased, so output increased by 30%. Due to competition from the Far East and changes in consumer habits (the establishment of shopping malls), Glovita stopped producing fashion gloves, and the focus of production was on the production and distribution of knitted work gloves.

From the second half of the 1990s, capacity-increasing investments were made.

Work glove models

In 2002, they practically only produced work gloves , nearly 11 million pairs per year. In 2004, the ownership structure was such that 54% of the shares were owned by the four-member management, 38% by the two largest customers (Riby SA and Seiz GmbH), and the remaining less than 10% of the ownership was in the hands of the municipality and small shareholders.

Glovita's production hall

Glovita Zrt. operates as a capital-rich company, selling 80% of its production as exports. The registered capital is 308,950 thousand HUF, and the equity exceeds 600 million HUF. In addition to satisfying domestic needs, its main markets continue to be Germany and France. The number of employees is around 130 people.

One of the best-known glove factories in Europe . They produce European-quality safety gloves for almost all areas of occupational safety, from thin cotton gloves to thick cut- and abrasion-resistant gloves. They also work to order and in contract work.

Japanese glove knitting machines work in fully automatic mode

The compilation was based on the study of Mrs. Orbánné Dr. Márta Horváth.

| INTERESTING FACTS |

|

They produce European-quality safety gloves for almost all areas of occupational safety, from thin cotton gloves to thick cut- and abrasion-resistant gloves. The materials used range from cotton, polyamide, polyester, to heat-resistant Nomex, heat and cut-resistant Kevlar, and other state-of-the-art yarn types. Some types of safety gloves |

|

Name variations: Heller & Asconas Rt. Hosiery and Glove Factory 1929– Hellas Ltd. 1940– Győr Knitted Glove Factory 1952– Glovita Győr Knitted Glove Factory 1984– GLOVITA Gloves Co. Ltd. 1992– Glovita Gloves Co., Ltd.2009– |

| LITERATURE, REFERENCES |

- 2003. Károly Lázár: The knitted glove . In: CÉLíránytű. No. 264. pp. 16-18.

- 2014. Orbánné Márta Horváth: The transformation of the textile industry in Győr from 1985 to the present day (in: GLOVITA Gloves Co., Ltd. p. 171-172. In: Driving forces of Győr's development. Monographs of the research on the Győr automotive industry district as a new direction and tool for regional development 1. Editor: János Honvári. Published by: Universitas-Győr Nonprofit Kft. Győr. p. 158-178.

Additional source:

The source of the color images without source is:

Related gallery

Back to the previous page!