Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Győr Special Purpose Machine Factory

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Related gallery |

| MEMORIAL SITE ADDRESS, ROUTE PLANNING |

| MIT LÁTHATUNK AZ EMLÉKHELYEN? |

Street view:

View of the Célgépgyár factory around 1990 (Rába photo gallery / János Szabó)

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

| BRIEF OVERVIEW |

|

The government established the Győr Machine Tool Factory, which specialized in the production of prototypes of machines and special purpose machines, on January 1, 1953. The factory was transferred from the Automobile and Tractor Industry Directorate to the supervision of the KGM Machine Tool Industry Directorate on July 1, 1957. Its name was then changed to the Győr Special Purpose Machine Factory. The supervisory authority selected the vacant building of the former Győr silk mill as the site for the factory. At first, simple structures were manufactured in the factory and gradually they progressed to the most modern aggregate special-purpose machines. The Győr factory operated as the Győr factory of the Tool Industry Works from 1963 until 1976, when it became the Special-Purpose Machine Factory of the Rába Hungarian Wagon and Machine Works. From then on, it worked for the large corporation. After the change of regime, Rába sold the factory to the German Hörmann holding in 1998. However, the owner's business hopes did not come true, so the factory was liquidated in 2003. |

| DETAILED COMPANY HISTORY |

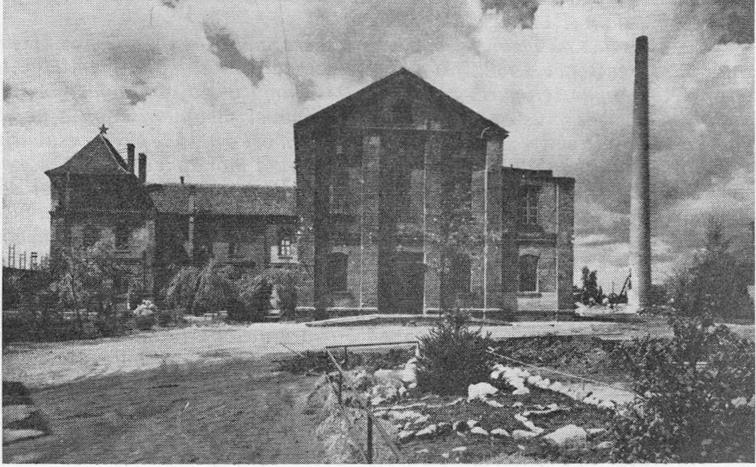

Silk mill in the 1920s

Image source: Free Royal City and County of Győr. Budapest, [1926]. Pallas Nyomda. Page 19.

The Győr Car Machine Tool Factory received the building of the former silk spinning mill in 1953.

After the nationalization of Hungarian industry, companies were reorganized, during which functions outside direct production were separated and a radical profile cleansing was carried out. The organizational measure created economic units specializing only in production and the production of a few products. During the profiling, a number of plant parts (the car department, the screw factory, the foundry on the site of the former Artillery Factory and the Industrial Estate Plants) were separated from the Győr Wagon Factory. The separated plants took with them 58% of the buildings, machinery and production equipment of the former main factory, and 42% of its production value.

The car department on the Wagon Factory premises first became an independent factory in 1951 under the name Győri Autógyár, and then on January 1, 1953, the Győri Célgépgyár separated from it. The Győri Autógyár operated as the Transmission Factory of the Csepel Autógyár between 1952 and 1956, and between 1957 and 1960 it became independent again under the name Transmission Factory Győr, and finally merged into the Győri Szerszámgépgyár, which was also separated from the Wagon Factory.

Old office building in the former silk spinning mill building. 1953.

The car department was unplannedly separated from the umbilical cord of the main factory, and all its connections with the wagon factory were suddenly severed, as no provision was made for service plants (energy supply, maintenance), suitable machines, or profiles. The best workforce remained in the main factory, while the detached units had to make do with unskilled labor, mostly from villages that had never even seen a factory from the inside. These problems – coupled with the well-known problems of the 1950s – led to the fact that the Car Factory was months behind schedule, thus hindering the work of the Csepel Car Factory. Therefore, the factory's gearbox and steering gear manufacturing department was relocated to the Csepel Car Factory in June 1952. From then on, the most complicated part of the drivetrain was manufactured in the youngest unit of the Szigetszentmiklós Car Factory, the Csepel Car Factory's Drivetrain Factory. The production of front and rear axles and transmission components remained in Győr.

The relocation also affected the employees of the department. Due to the distance, daily commuting was out of the question, and the working conditions in Szigethalam for the workers from Győr, who were separated from their families, were very poor. Their accommodation and care were not properly taken care of, so they soon returned to Győr, which could not be prevented even by the administrative measures in force at the time.

Special purpose machine factory, old gate

Photo: János Szabó (Rába Photo Gallery)

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

The central management body of the sector, the Automobile and Tractor Industry Trust, wanted to avoid the dispersion of skilled workers with special qualifications among the various companies in Győr, so the government instead founded the Győr Automobile Machine Tool Factory on January 1, 1953. The name of the plant changed to Győr Special Purpose Machine Factory on July 1, 1957, when it was transferred from the Automobile and Tractor Industry Directorate to the supervision of the KGM Machine Tool Industry Directorate.

At the start, the Győr factory was the only special-purpose machine manufacturer in Hungary. Later, other companies joined the special-purpose machine manufacturing (in addition to the Győr Special-purpose Machine Factory, such work was carried out at the Machine Tool Development Institute and the Csepel Iron and Steel Works).

In the first few months after its formation, the company, which was still in its “infant phase” and did not have its own premises, operated in the Győr Gearbox Factory. Its own “machinery” consisted of three obsolete machine tools waiting to be scrapped and a welding dynamo in poor condition. They performed their work on the Gearbox Factory’s spare machines on a courtesy basis. The management and administration worked crammed together in the Gearbox Factory’s boardroom.

The central management trust chose the former silk spinning factory building on Csipkegyári Road as the site for the factory. The silk spinning factory, located near the Rába Bridge, was seriously damaged during the bombing of the city. The Car Machine Tool Factory received this completely neglected factory site, which was not originally built for the purpose of an iron industry plant. The factory, called “owl castle” by the residents of the area, was cleaned up in a few months and renovated to such an extent that it was able to accommodate its small number of machine tools and 120 employees on March 28, 1953. After moving in, renovation and expansion of the factory with new buildings continued for years. The machining workshop was arranged on the ground floor of the main building, and the assembly locksmith workshop was on the upper floor. The design and plant management were located in the wing building on the railway side, while payroll and accounting continued to operate in the area of the Gearbox Factory, several kilometers away, because there was no suitable building available at the new site. Families lived in the building in front of the gate and on the ground floor of the wing building, and they could only be moved out years later, because there was no empty apartment in the city that could be allocated to them. They assembled their machinery from discarded, transferred, and redundant equipment from other companies, which they usually brought into working order themselves. In the absence of suitable machinery, much work had to be done in cooperation, which had a very negative impact on quality and adherence to deadlines.

The Győr Car Machine Tool Factory received the building of the former silk spinning mill in 1953.

At the start, most of the employees of the Car Tool Factory were recruited from those who had relocated from Szigetszentmiklós or from those who worked in the car tool factory of the Győr Transmission Factory, as well as from those who worked in technology and construction. Its task was defined in the founding document as the preparation of prototypes of iron industry machines and the production of special purpose machines primarily for the car and tractor industry. In addition, the Car Tool Factory also produced car parts and assembly tools. For example, in 1955, tool sets for the repair of Ikarus buses intended for export to China were made here. Two prototypes of the first Hungarian rubber-wheeled universal row-cultivating tractor designed at the Vehicle Development Institute were also made in the Győr Car Tool Factory. From July 1, 1957, after the change of the direct supervisory body, the task of the Győr Special Purpose Machine Factory became to satisfy the special purpose machine needs not only of the car industry, but of Hungarian industry in general. In addition to the production of prototypes of its own special purpose aircraft, the production of prototypes was no longer part of the factory's profile as the production of special purpose aircraft increased.

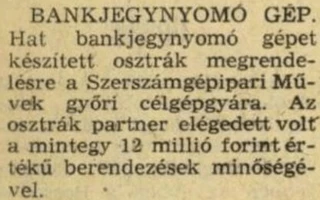

Pest County Newspaper, March 8, 1959, No. 57, p. 1.

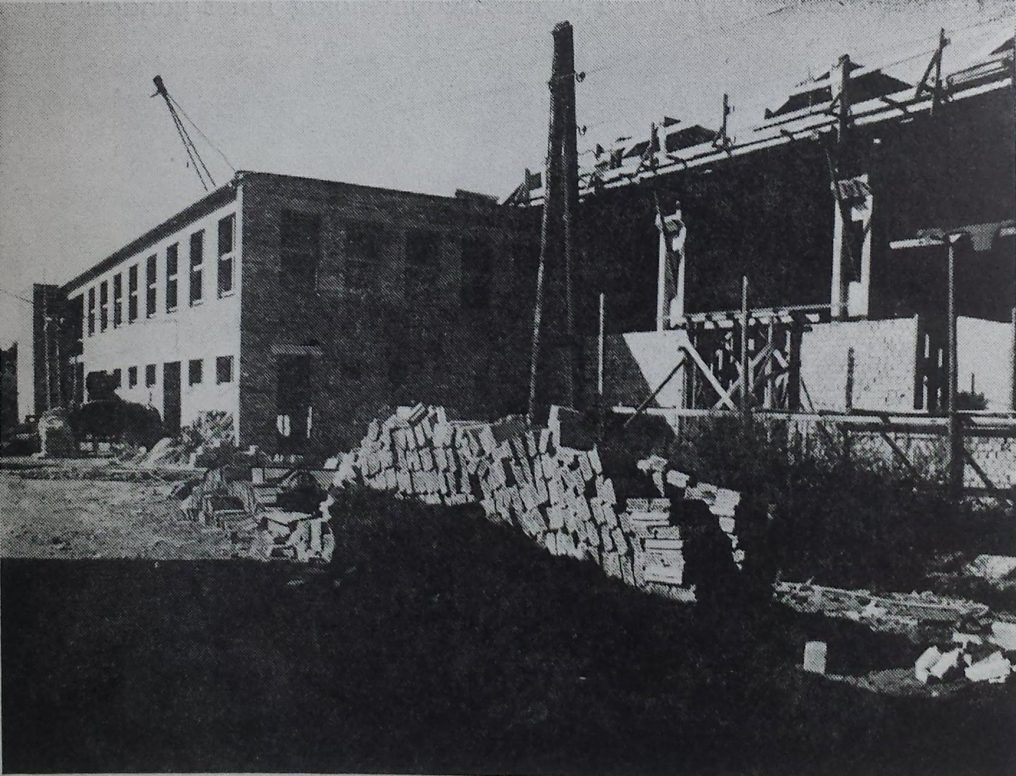

Working conditions improved greatly between 1953 and 1955, with a changing room and a washroom, the machine shop roof replaced and a crane runway built. The editors and technicians were able to move into a suitable, heated building in 1955. They also installed a dining room with a sideboard. However, the real change came in 1963 with the first new hall – and the associated offices and social facilities.

The new workshop hall is being built.

The new production hall was connected to the one-story building, where the 70-person editing, the company doctor's room, the restaurant and the social rooms were located. The workshop, which was built at a cost of 35 million HUF and originally built for mechanical engineering purposes, was equipped with a crane runway, compressed air and modern lifting equipment to make the hard physical work easier. The construction of the training workshop and the new machines arriving at the factory made it possible to reduce external cooperation to an acceptable level.

In the III. Five-Year Plan (1966-1970), new significant developments worth approximately 70 million HUF were launched, i.e. the production of hydraulic units for machine tools was concentrated in the Győr plant. During the II. Five-Year Plan, among the machine tool factories, in addition to Győr, the Esztergom Machine Tool Factory also received significant investment resources, the latter being primarily responsible for the production of high-precision machine tools. The development was carried out in such a way as not to hinder continuous production. A 4,400 square meter workshop with associated social facilities was built on the site of the old workshop building.

Workshop hall in the 1980s

Photo: János Szabó (Rába Photo Gallery)

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

The two-story residential building opposite the entrance (where the managers of the silk spinning mill lived before the war) was demolished and an 8-story office building was built in its place. The offices scattered throughout the factory area were concentrated here and the editing department was given a bright, modern space. The production hall, which was completed in 1963, was extended and the warehouse demolished during the development was moved there.

The new office building. 1988.

Photo: János Szabó (Rába Photo Gallery)

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

At first, very simple products and dwarf aggregate units were manufactured, and the proportion of special purpose machines only increased from the mid-1950s. The first products were simple structures that could not really be called special machines, let alone machines. At the start, they produced welded sheet metal mold cabinets, gantry cranes, and factory transport carts for foundries. In 1954, the first machine of their own design, welded for milling truck brake shoes, was completed. This and the machines manufactured in 1955 were also completely mechanical. In 1956, the first 5-ton hydraulic press was completed, which was a sought-after product of the factory for a long time. The first serious mechanism that could be called a special machine was the piston ring mirroring machine, and then the fiber drawing machine.

From the beginning, the unique and purpose-built machines were designed by the company's designers, who tried to keep up with the latest international trends.

Among the products that brought fame, recognition and, last but not least, financial success to the Célgépgyár, the first to be mentioned is the drawstone grinder. The machine, which was also presented at the Leipzig International Fair, represented the world standard of its kind at the time. The drawstone (contrary to its name) is a tool made of hard metal, usually conical in shape, which is used to reduce the diameter of wires, rods and shapes. The material is drawn through this tool with a gradually narrowing cross-section (usually several times), which finally acquires the required size. This special machine was constructed in Győr for the grinding of this special, high-value tool.

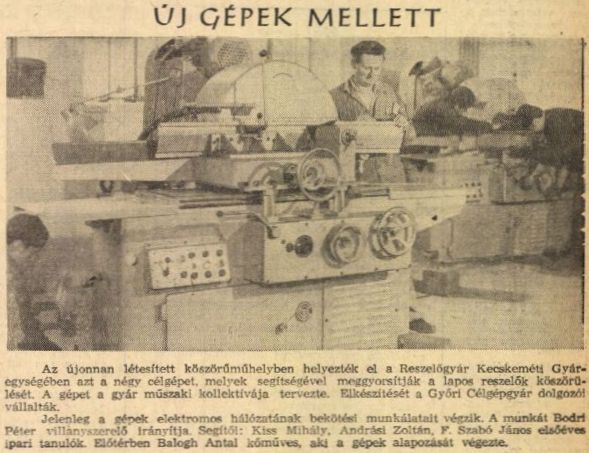

Petőfi Népe, April 24, 1963, No. 94, p. 3.

The orbital sander is a type of scissors used to cut out any shape from sheet metal, which has a stationary blade and a blade that vibrates at 1000 strokes per minute. When it was designed, pessimists said that the market was saturated. However, the design was so successful that after its release, the company's entire orbital sander production capacity was booked in Hungary for two years in advance. Its lasting success at home and abroad was due to the fact that the machine was constantly being improved.

Déli Hírlap, December 16, 1971, No. 296, p. 6.

They also made unusual machinery here, such as a cigarette-packing machine for the Lágymányos tobacco factory, and a pneumatic carousel for the Amusement Park, where a dozen two-seater airplanes were placed on rotating rods, the height of which could be raised or lowered by those sitting inside using joysticks.

The carousel that once operated in Kiskút was made at the Célgépgyár. 1960s

Photo: From the collection of Péter Békefi

Source: https://regigyor.hu/gyarvaros/a-majus-1-kulturpark/

The newspapers of the time wrote about “huge” machine lines and machine groups when they praised the semi-automatic cylinder head machining line made for the Csepel Automobile Factory and the machine made for the production of Heller-Farkas cooling elements. These were of course much larger than a drawstone grinder, but they were incomparably smaller than the machining lines of the 21st century. Their novelty lay in the fact that instead of the mechanical movement of the previous machines, they now operated on the basis of electropneumatic and electrohydraulic principles.

Their special purpose machine for machining faucets and other fittings, which performed metalworking from three directions at once, also served a great service in the Mosonmagyaróvár Metal Fittings Factory. We can truly understand the significance of this machine if we know that machining was the bottleneck of production in almost all domestic machine factories at that time. Together with the Institute of Mechanical Engineering Technology, they designed a gear grinding machine that reduced the operation time from 40-50 minutes to 2 minutes.

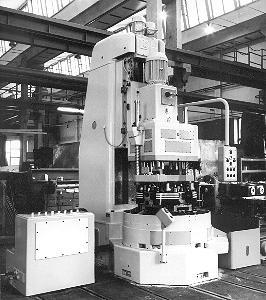

In 1957, the factory was commissioned to construct a special purpose machine for producing cylinder heads for truck engines. This six-unit special purpose machine with a rotary table was the first high-productivity complex machine group manufactured in Hungary. The special purpose machines performed all cutting work except for the flat side surface of the cylinder head. The rotary table was made in the factory, and the machining units arrived from the GDR at that time. The Special Purpose Machine Factory crossed the threshold of “adulthood” with this semi-automatic equipment. The future meant the production of standardized aggregate units, which began in Győr with this cylinder head machining unit. The continuation was so successful that the Ministry of Metallurgy and Mechanical Industry entrusted the Győr Special Purpose Machine Factory with the development and production of all standardized, uniform parameter aggregate units from 1963. Until then, the Csepel Machine Tool Factory and the Machine Tool Development Institute were responsible for the development of standardized construction units.

Pest Egei Hírlap, February 21, 1959, No. 44, p. 3.

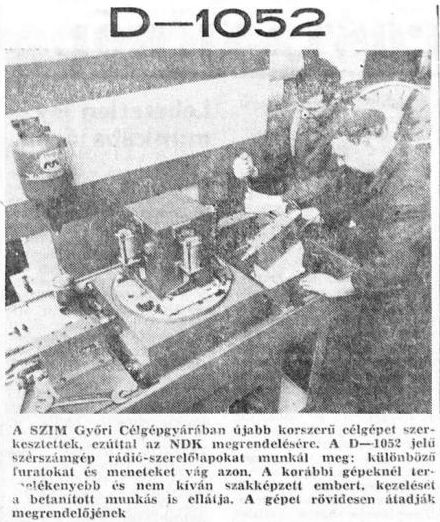

Southern Hungary, December 8, 1968, No. 288, p. 13.

The factory manufactured more than 300 types of special-purpose machines from 1953 until it was merged with the Győr wagon factory. The range ranged from the simplest mechanical structure to hydraulic and pneumatic movement, from simple custom-designed machines to the most modern aggregate machines, from manual control through electrical elements to pneumatic and electronic solutions, from rough machining to strict tolerances, from manual service to fully automatic.

When the factory was founded, special-purpose machines were virtually unknown in Hungarian industry, and the vast majority used universal machine tools that could solve almost any production task. The proportion of special-purpose machines did not exceed 2-3% even in the 1960s. Machine factories were wary of special-purpose machines, and hardly any orders were received for such machines, because due to the small series, special equipment was still expensive at that time, and their standardization was delayed, so producers stuck to the usual and even underestimated Hungarian special-purpose machine production a little.

Nógrád Népújság, November 17, 1962, No. 92, p. 1.

The demand for special production equipment increased when manufacturing companies began to produce larger and larger series of each product, and users realized that special purpose machines constructed based on the principle of modest construction were also suitable for performing multiple tasks.

Népújság, April 24, 1964, No. 95, p. 6.

The factory's production structure was completely transformed in a decade. From the second half of the 1950s, the plant began to produce an increasing proportion of special purpose machines, meaning that it began to perform the task for which it was originally established. In addition to technology, the fulfillment of the plans required a skilled workforce.

Due to the nature of the plant, it was not at all one of the large plants in Győr, the number of employees increased from the initial 120 to 225 by 1963. The atmosphere in the factory was almost family-like, everyone knew everyone, drinking and unexcused absences were rare within the plant. The workers here were proud of their highly qualified, creative work. They were aware that they had to produce “little but very good” here. A product jury consisting of their own experts qualified the new products, which made suggestions for correcting any possible errors, thus ensuring that even the first machine (which was possibly the last of its kind) would operate flawlessly.

Nógrád, June 6, 1967, No. 131, p. 6.

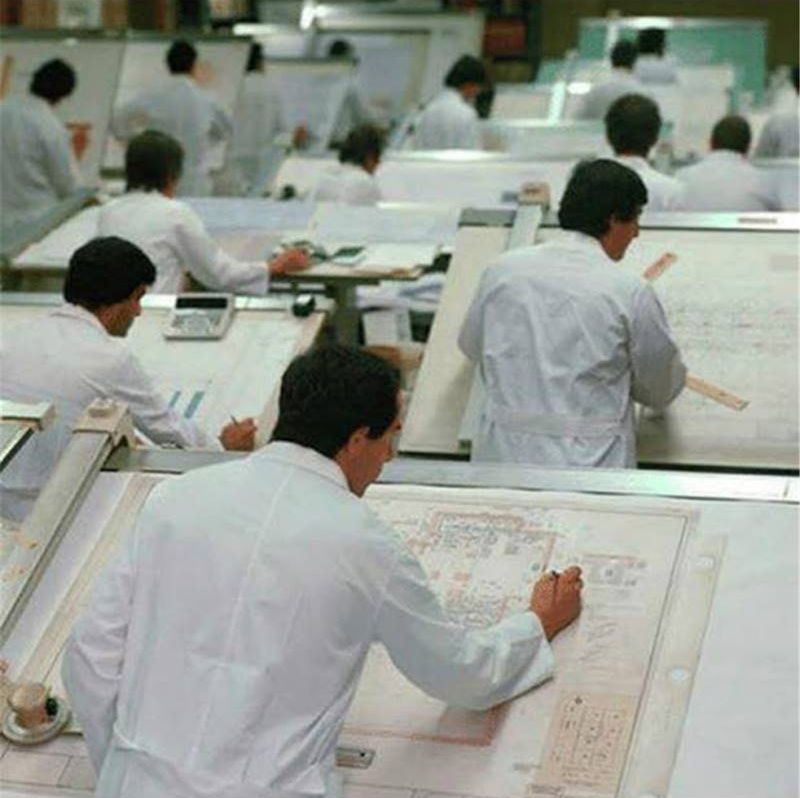

The composition of the employees was quite peculiar. Nowhere, in any production plant in Győr, was the ratio of engineers and technicians as high as in this plant, where every function was filled by an engineer. In 1962, 14 engineers and 52 technicians worked at the Célgépgyár, which employed 260 people. The production of special-purpose machines was essentially prototype production, and usually only 1-2 of the complex machine lines capable of performing a variety of operations were made. Here, almost every machine was a unique creation that had to be constructed separately. Serial production was unknown here, and often the prototype was also the copy that was sold.

Drawing boards with drawing machines. From the collection of György Magyar.

Pest County Newspaper, November 7, 1965, No. 263, p. 4.

In the first three decades of the socialist Hungarian economy, there was little difference in wages within the same profession, but the wage differential was also quite small between different occupational categories (technical, administrative, manual), and within these, between skilled, trained and unskilled workers. Among the factories in Győr, the average wages were generally higher in the Célgépgyár, which resulted from the higher level of professional qualifications, more precise work, and higher quality requirements.

Northern Hungary, March 4, 1971, No. 53, No. 71, p. 5.

Exports began in 1955 with technically simple equipment, and then became permanent from 1960 with a special-purpose injection needle making machine delivered to the Egyptian medical instrument factory. Pipe-making and pipe-sharpening machines, hydraulic controllers were delivered to the Soviet Union, the GDR and Czechoslovakia. However, despite exports, the Special-Purpose Machine Factory primarily manufactured special-purpose machines for the Hungarian metallurgical and mechanical industry ministry companies that produced large domestic series.

Logo and product label

On July 1, 1963, the Machine Tool Works was established, which merged the Budapest, Kőbánya, and Esztergom Machine Tool Factories, the Metal and Machine Tool Factory, the Győr Special Purpose Machine Factory, the Light Industry Machine Tool Factory, the Nagymaros Machine Factory, the Machine Tool Accessories Factory, and the Machine Tool Development Institute into a large national corporation. From then on, the Győr factory continued its previously started activities as the Special Purpose Machine Factory of the Machine Tool Works until 1976. Within the framework of the large corporation, the Győr Special Purpose Machine Factory operated relatively independently, concluding its own business transactions, but its contracts bore the signature and account number of SZIM.

Pest County Newspaper, February 18, 1971, No. 41, p. 3.

The Célgépgyár had been working for the Győr wagon factory since the 1960s. This activity became particularly significant after the Célgépgyár became capable of producing medium and large purpose-built machines. In the wagon factory, the production of 10-ton truck and bus rear axles began in the mid-1960s. The transfer line required for the production line, the device required for clamping and transferring the workpieces, was manufactured by the Célgépgyár based on a cooperation agreement with an English company.

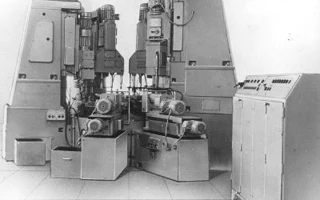

Connecting rod machining machine

Source: http://www.szerszamgepgyartas.hu/hun/factory/szim/szim_08.htm

When the production of large-scale 10-ton rear axles and Rába-MAN licensed engines began, a large number of special-purpose machines and automatic machines appeared in the wagon factory. The engine factory was supplied by the Renault-MAN-Ferrostaal consortium. 17% of the machines installed were special-purpose machines, 32% were automated, and 51% were high-end universal machines. The situation was similar when developing the chassis production. In the latter, 35% of the initial program cost of more than 2 billion HUF was spent on the purchase of special-purpose machines, automatic and semi-automatic program-controlled machine lines. At that time, a large number of special-purpose machines appeared in the wagon factory, most of which were initially purchased from Western suppliers. During further developments, highly qualified specialists were needed for the domestic production of the special-purpose machines and for the renovation and development of existing machine lines, whose profession it was and who had already gained sufficient experience in this.

SZIM's Győr General Purpose Machine Factory was purchased by CEO Ede Horváth on April 1, 1976 for 100 million HUF, which then worked for the giant company as the Rába General Purpose Machine Factory.

Product label with logo

The Ministry of Metallurgy and Machine Tools – as the supreme authority embodying the state owner – simply attached SZIM’s Győr Special Purpose Machine Factory to MVG. The move was justified by the fact that the demand for Rába’s products on the world market had increased significantly. The large factory in Győr was now supplying chassis not only to socialist countries, but also to the USA. This led to an increase in Rába’s demand for special purpose machines, which it had previously imported primarily from capitalist countries.

After Rába merged with the Célgépgyára, they did not undertake any external work, they only worked for the Wagongyára.

Shortly after the accession, they were faced with a serious task. The demand for engines manufactured in Rába became so great both at home and in the socialist countries of Eastern Europe that the engine factory, originally equipped to produce 13,500 engines and spare parts per year, had to be expanded. In the early 1970s, MAN stopped producing the engine type for which Rába had purchased the license in 1967. From the machines dismantled in the Nuremberg factory, they bought the machinery lines that were a bottleneck in engine production in Győr, with which they were able to double engine production in a short time. They were able to rely on the experience of the specialists of the special-purpose machine factory when adjusting the cylinder head and crankshaft machining lines.

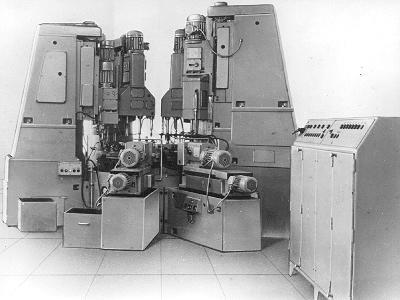

Crankshaft machining machine

Source: http://www.szerszamgepgyartas.hu/hun/factory/szim/szim_08.htm

The engine license purchased from MAN in 1967 was for the production of an engine with a design that was more than twenty years old (and had been improved several times in the meantime). This power unit was so much better than any of its competitors manufactured in Eastern Europe that there was no need for further development for decades. The Austrian List Institute was commissioned to design the engine with higher performance, fuel economy, and lower emissions, and by the end of 1983 it had constructed the zero series of new engines based on the old engine.

The additional equipment that allowed the new engines to be produced on the existing production line was manufactured at the Rába Célgépgyára. However, the customers (primarily the Soviet Union and other former socialist countries) did not assume the additional cost of the new engine, so only very few of the developed engines were produced, and the original Rába-MAN engines continued to be installed in Hungarian road vehicles.

Aerial photo of the factory. 1984.

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

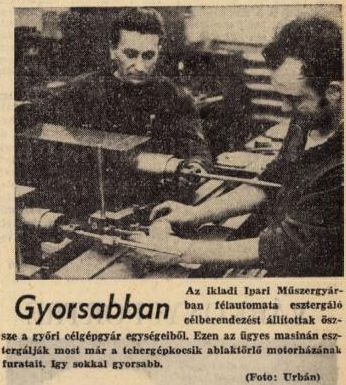

Some of the machines delivered to the Rába engine factory in the late 1960s were inevitably outdated by the 1980s. The specialists of the special-purpose machine factory designed and manufactured better, more modern ones instead. Ones in which the workpiece was clamped automatically and the machining took place from several sides at the same time. Manual physical work was eliminated with mechanical structures that made the workers' work easier. Later, they also worked in the chassis factory.

Rába survived the 1989 regime change only through great difficulties and significant self-mutilation. All of its key markets collapsed at once, including the main buyer of the engines and chassis manufactured here, the Soviet (and Eastern) market, Ikarus, and the large agricultural companies that purchased the high-performance power plants and the work equipment manufactured for them.

After Ede Horváth's retirement, the new management's main concern was to divide the giant company into smaller units and divisions so that the factory could be more easily privatized.

This fate also befell the Rába Special Purpose Machine Factory, which was purchased by Hörmann and Bárdi Autó after the change of regime. Hörmann's business plan – which wanted to produce special purpose machines for Audi – did not materialize, so the special purpose machine factory was liquidated in 2003.

The compilation was based on the study of Dr. János Honvári.

Continue to the detailed study

| INTERESTING FACTS |

|

On the 60th anniversary of the factory's founding and the 10th anniversary of its closure, former employees of the special purpose machine factory placed a commemorative plaque on the wall of the office building that stood on the factory's site.

Győr Plusz public weekly, 2013. Nov. 22. p. 11.

|

||

|

Did you know what conditions the workers in the special machinery factory started working under? The initial abnormal conditions are well illustrated by the following cases. There was only one two-ton crane available in the ground-floor workshop hall, and not even that many in the assembly shop upstairs. In the absence of factory transport and lifting equipment, heavy workpieces had to be moved by hand around the factory. Everyone on hand, from the assistant worker to the engineer, took part in the hauling. You can imagine how cumbersome and, not least, dangerous it was to lower the multi-ton machines assembled in the assembly shop upstairs to the ground floor with a single one-ton window lift. To do this, they cut a large opening in the ceiling, which was reinforced before moving the workpiece so that it would not fall off, then rolled the monster to the hole, through which the equipment was lowered to the ground with the help of two pulleys and a few trestles and the strained muscles of many people. The opening was boarded up until the next action. Sometimes the 8-10 ton machine monsters were first dismantled, a wall was knocked down to move them, and this was the only way they could be lowered. In the absence of a suitable door in the machine shop, they were forced to open the wall and bring in the raw materials by hand through it. The opened wall was covered with a tarpaulin. The roof of the blacksmith shop was soaked, rain and sleet dripped down the necks of the workers there. It was impossible to heat the offices, and the poorly sealed windows made the room cold and drafty. The technicians and administrators worked in gloves with cut-off sleeves in winter. The workers ate their food standing next to the kettle in the shed called the dining room, from the pots they had brought with them, which they then washed at the yard tap. |

|

Name variations: Győr Car Tool Machine Factory January 1, 1953 – Győr Special Purpose Machine Factory July 1, 1957 – SZIM Győr Special Purpose Machine Factory 1963 – Rába Célgép Ltd. 1976 – Hörmann Célgépgyár Ltd. 1999 – 2003

|

||

| LITERATURE |

- [1963.] 10 years in the service of the development of the mechanical industry. The history of the development of the Győr Célgépgyár. Compiled by: the “Célgép” committee of the GTE Győr group. Győr, Győr-Sopron county printing house. 36 pages.

- Old Győr website, historical summary titled Győri Célgépgyar

Source: https://regigyor.hu/ujvaros-sziget/gyori-celgepgyar/

Related gallery

Back to the previous page!