Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Győr Distillery and Refinery Co.

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Related gallery |

| ADDRESS OF THE MEMORIAL SITE, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

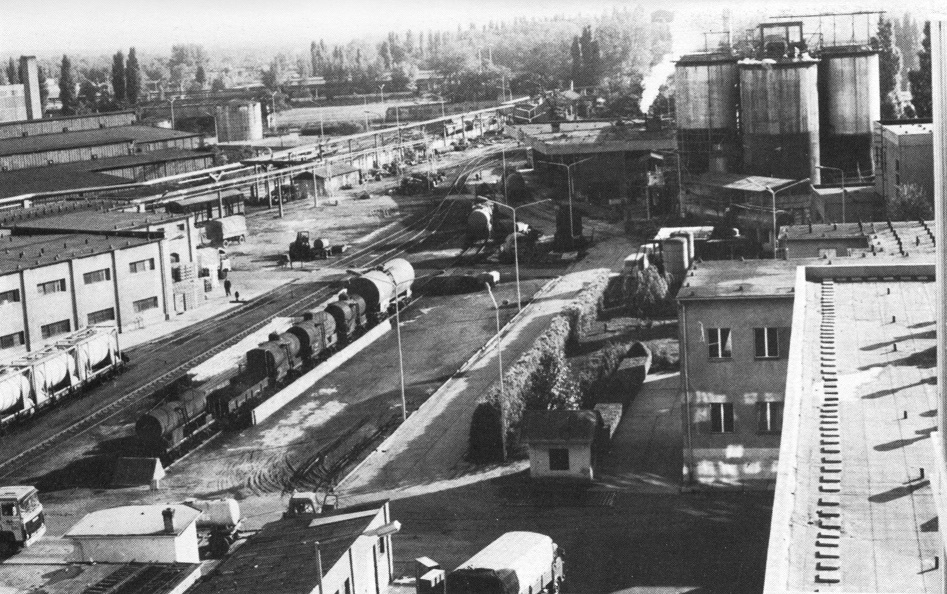

The distillery buildings are visible from every point on Budai Street . The memorial plaque is located on the wall of the red brick brewing and refining factory unit that remains from the time of its founding.

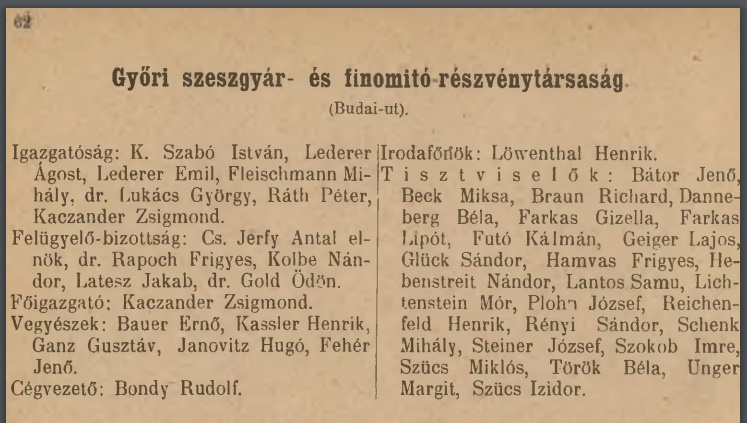

Across the street – in an area enclosed by a concrete fence opposite the factory – are the company's alcohol and molasses storage tanks.

A few industrial historical relics (e.g. old machinery, railway tank car) are preserved on the factory premises, which may be open to visitors in the future.

Street view :

Győr Distillery and Refinery Co. - Aerial photo 2018

Photo: Zsolt Andorka

Győr Distillery and Refinery Co. - Aerial photo 2018

Photo: Zsolt Andorka

Győr Distillery and Refinery Co. - Main Building 2018

Photo: Zsolt Andorka

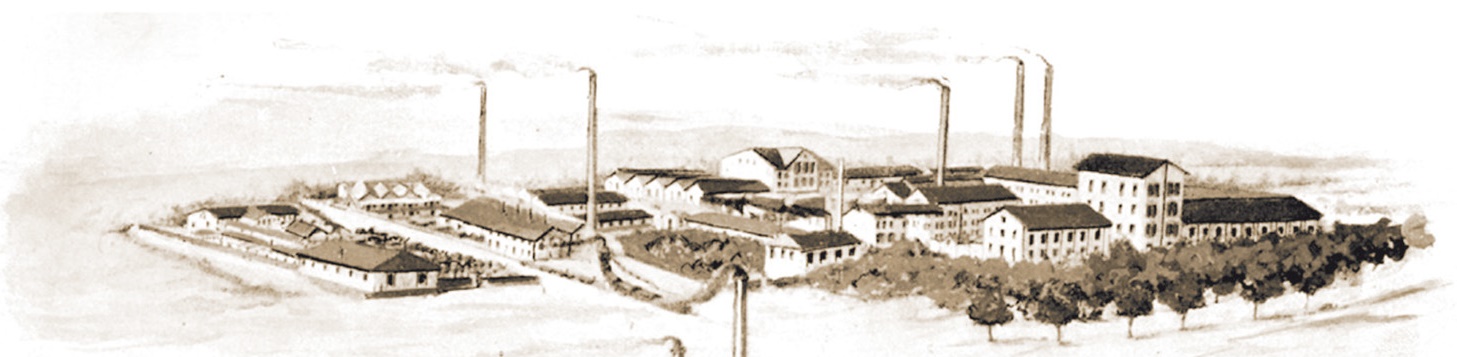

A picture from the past:

| BRIEF OVERVIEW |

|

The Győr Distillery and Refining Co. Ltd. was the first industrial enterprise in our city, originally established as a joint-stock company. The company was founded on May 28, 1884, by local entrepreneurs, mostly merchants. The majority of the company's shares were acquired by the Austrian Wiener Bankverein in the late 1880s, and then by the Lederer family in 1895. Ágoston Lederer, a major Viennese entrepreneur, ran the Győr Distillery from 1895 until his death in May 1936, when the state expropriated the company in 1938, with compensation for the owners. During World War II, 90% of the factory buildings were destroyed, but the brewing and refining unit that still exists today survived the bombings, so the factory was put back into operation after the war ruins were restored. The two most significant investments of the socialist era were the feed yeast plant established in the mid-1960s and the new cooking and refining building built in the 1970s. After the change of regime, the factory was privatized, and the controlling stake has been in the hands of György Folláth's family since then. |

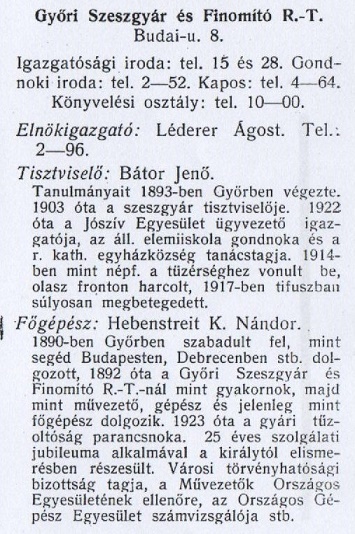

| DETAILED COMPANY HISTORY |

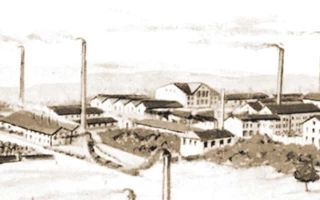

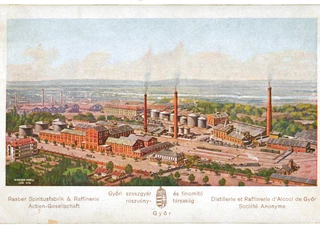

The first industrial enterprise of the city of Győr – already established as a joint-stock company – was established on May 28, 1884 with a share capital of 800,000 forints . The initiators of the enterprise were among the city's richest grain, crop and pork merchants and entrepreneurs, who, in addition to their commercial activities, participated in the management of local banks, infrastructure enterprises and factories as owners, chairman of the board, CEO, supervisory board member and official, and also sat on the city's municipal committee.

The factory was built on the same plot on Budai út where it has stood for more than 130 years. Two important aspects were taken into account when choosing the site: industrial water should be close by the Mosoni-Danube and the railway should be within reach. At that time, there was still free space behind the plot all the way to the Danube, the so-called city meadow, and opposite the distillery plot was the city model garden, so the factory had the opportunity to expand in both directions.

The construction of the distillery began on September 1, 1884, and its ceremonial inauguration took place on May 28, 1885, on the first anniversary of the founding general meeting. The “soul” of the factory, its most important equipment, the cooking and refining equipment, were purchased from Germany, and most of the other machinery from the Czech Republic. At first, the spirit was made from grain, mostly corn, and the distillery sludge that was produced as a by-product was used for cattle fattening.

The majority of the company's shares were acquired in the late 1880s by the Austrian Wiener Bankverein, which played a major role in the economic life of Győr, and then in 1895 by the Lederer family.

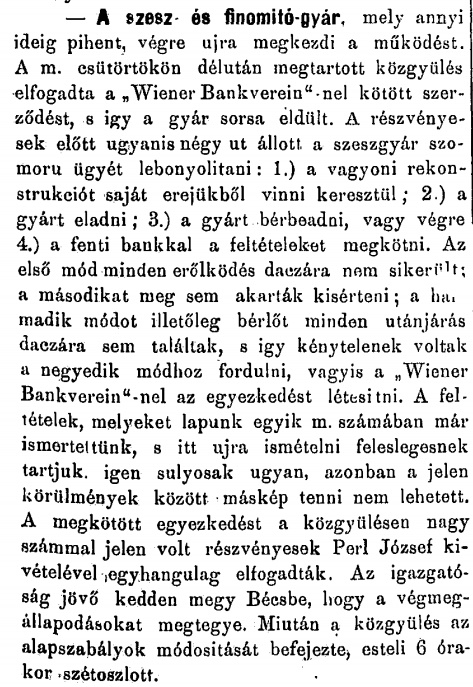

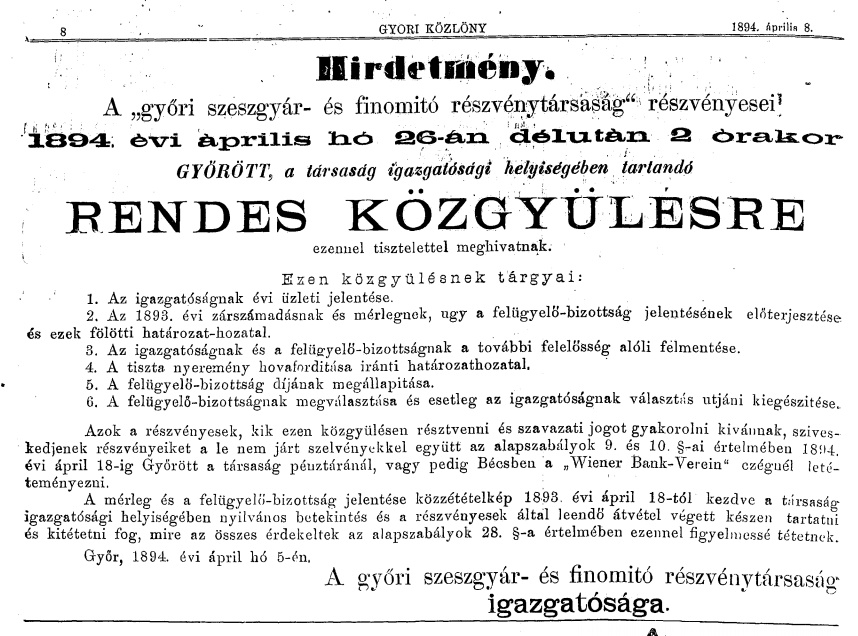

The Győri Közlöny reported on the agreement reached with the Wiener Bankverein on January 20, 1889.

Source: http://edok.gyorikonyvtar.hu/

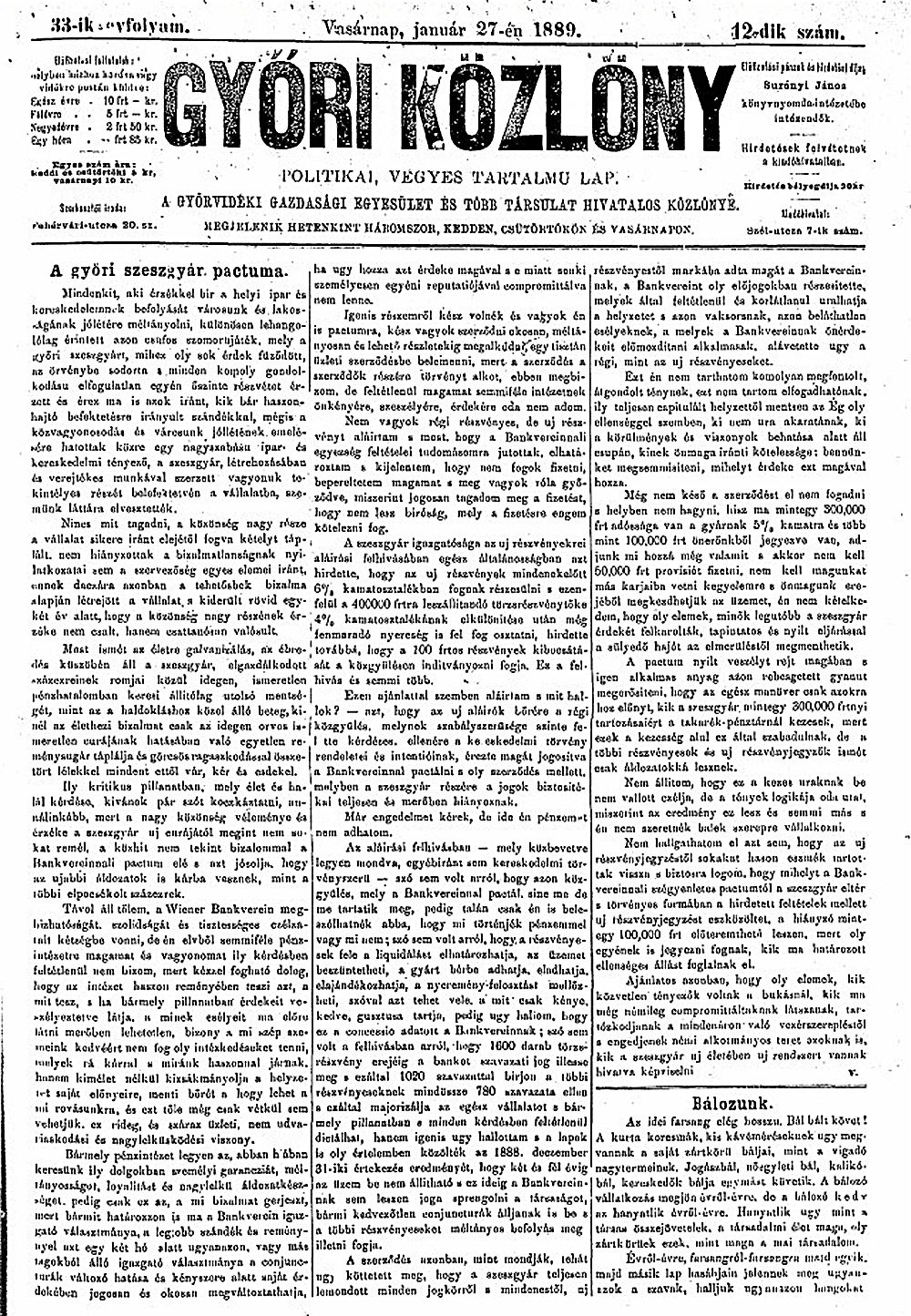

The Győri Közlöny, dated January 27, 1889, published a full-page article on its front page regarding the contract concluded with the Wiener Bankverein, which aroused mixed emotions.

Source: http://edok.gyorikonyvtar.hu/

In 1891, the factory stopped purchasing corn as raw material and switched to molasses. The cattle were sold, fattening was stopped, and potash was produced from the by-product of the alcohol production. The potash factory was set up in the largest cattle barn that remained empty, the product of which was used partly by glass factories and partly by chemical factories to produce potassium, soda and other chemicals. The molasses slurry, which contained nitrogen and mainly potassium (which was no longer suitable for direct animal feed), was also used for fertilizer on agricultural farms.

source: http://edok.gyorikonyvtar.hu/

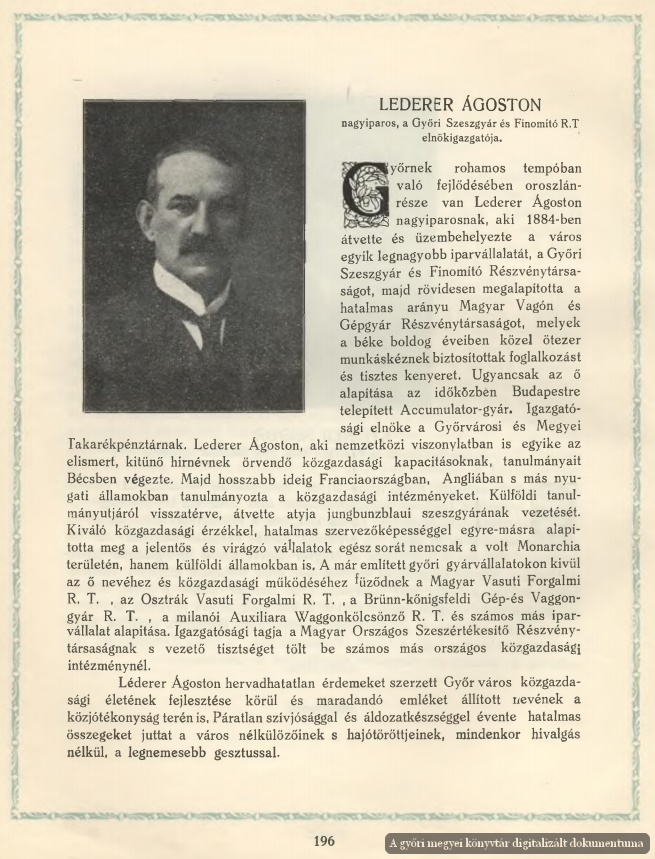

The factory was headed by Ágoston Lederer, a Viennese entrepreneur , for 41 years from 1895 until his death in May 1936. He is responsible for the renewal of the Győr Distillery, which had gone through many crises and setbacks since its founding.

The Győr Distillery and Refinery was the most significant enterprise in the manufacturing industry of Győr until the establishment of the wagon factory. According to the 1900 census, there were 23 factories in Győr that employed more than 20 employees. After the wagon factory (1,556 people), the distillery is the second largest factory in this respect (264 people).

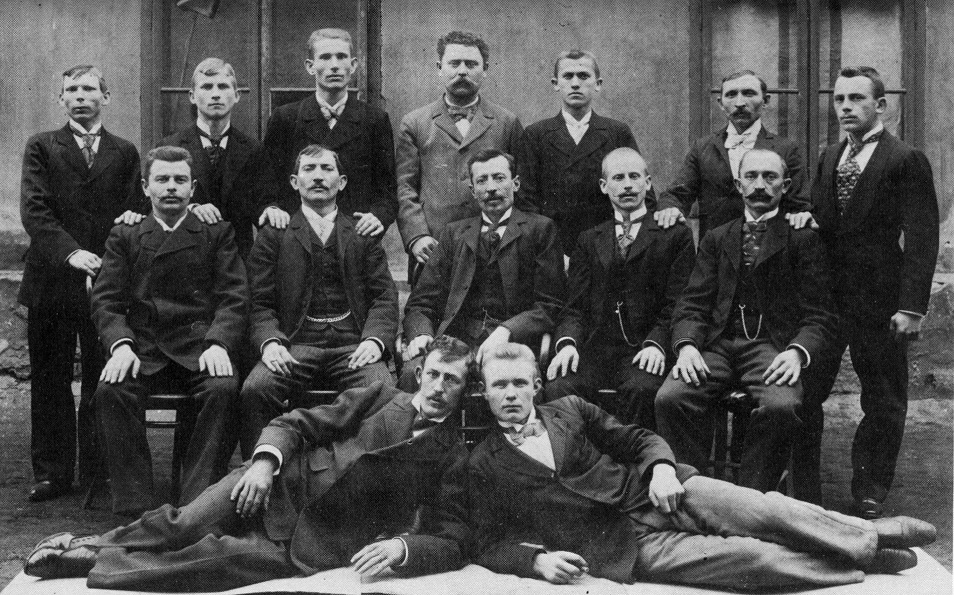

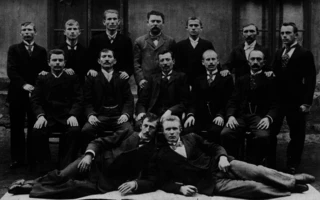

Group photo of the factory's foremen and skilled workers from 1902

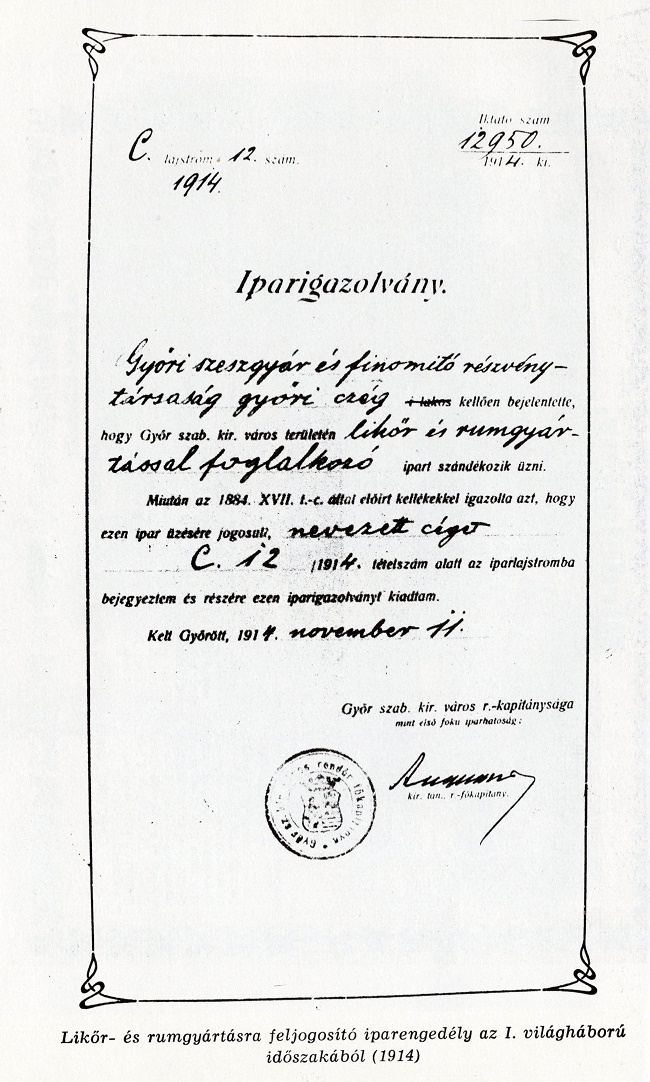

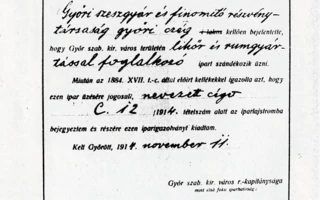

Industrial license for the production of liqueur and rum (1914)

Due to the territorial annexations following World War I, the amount of molasses, the basic raw material of the Győr distillery, decreased significantly, so from 1920 onwards, in Győr, in addition to molasses, spirit was also produced from sugar beets, and the equipment was also suitable for producing spirit from corn and potatoes. After the war, demand for refined spirit fell among both industrial consumers and beverage manufacturers. From the mid-1920s, the factories managed to increase production primarily through the growing export of spirit.

View of the factory after World War I from the direction of Budai Road

The booming economy of the spirits industry was interrupted by the Great Depression of 1929–33. Not only domestic consumption, but also exports fell significantly in these years. The Győr distillery could not even utilize a quarter of its capacity during the years of the crisis. It was a real blessing, a gift for industrial distilleries, that the government ordered the mixing of gasoline with dehydrated alcohol at this time. From then on, in Hungary until the end of World War II, motor spirit, i.e. gasoline mixed with 99.9% dehydrated alcohol in a ratio of 1:5, was used to power engines. In the 1936/37 production season, more than half of the alcohol sold on the domestic market was already used in this way.

The first major fire in the factory's history occurred in 1917, when the potash factory burned down completely. The other major fire broke out in the main building on November 12, 1926, during which the roof of the cooking and refining building and a significant part of the equipment located there were destroyed by fire. The restoration took several months. The factory was insured, so the damage was reimbursed in both fires.

Between the two world wars, the distillery also began producing new products. They produced grape sugar, potato starch syrup, car coolant antifreeze, and pesticides. The profit potential of the sugar business and the growing shortage of molasses prompted Lederer to establish a sugar factory on the distillery site with an investment of 12 million pengő, with the involvement of a Swiss investment group also interested in distillery production. The Transdanubia Sugar Factory Co., Ltd. was formally established on June 14, 1931. After several appeals, the company received a site permit, but the factory was ultimately not built, partly due to the tightening of legal conditions and mainly due to the worsening profit prospects.

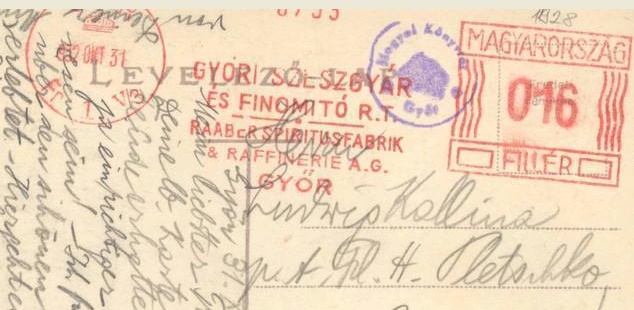

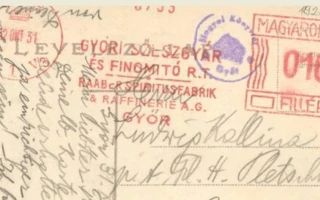

Title page of a postcard with the seal of the Győr Distillery and Refinery RT, sent in Győr on October 31, 1932.

Source: http://edok.gyorikonyvtar.hu/

Detailed description and monograph of the administratively united counties of Győr-Moson-Pozsony and the city of Győr with legal force and royal title for the years 1929-1930. Editor-in-chief Sámuel Kerekes, editor Barnabás Enyedy. 1930. p. 509.

With the 1938 Act XXX on the sale of spirits, the state monopolized the production of spirits and on September 1st expropriated the three industrial distilleries, including the one in Győr, whose standard production exceeded 10,000 hl in the 1937/38 production season. The owners were compensated. The nationalization only concerned the distillery and refining plants and their related facilities; the potash factory, the grape sugar factory and the plant protection products factory, as well as the arable land and house belonging to the factory site, remained in the hands of the Lederer family.

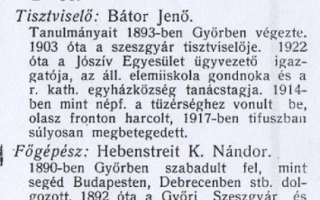

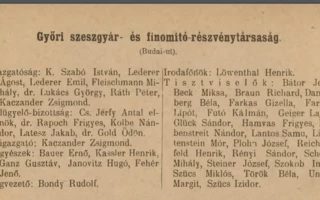

Győr city administrative directory for the year 1940

source: http://edok.gyorikonyvtar.hu/?docId=52525

During World War II, the distillery was not considered a primary military target, but since the wagon factory was its immediate neighbor, almost 90% of the distillery buildings were destroyed in multiple air raids.

The engine room after the bombings of 1944

Thanks to a miraculous coincidence, the largest building of the factory, the still-standing brewing and refining unit, was spared by bombs and thus the factory was put back into operation after the war ruins were restored. In parallel with the slow restoration, the production of the distillery increased. The molasses sludge was released into the Danube for years due to the destruction of the potash factory. In the autumn of 1947, the Distillery Directorate leased the chemical plant, which was still privately owned, for 10 years, but only the sludge thickener and the sludge coal burner were put into operation in Győr; after the war, potash production was no longer carried out here. The restoration of the war damage – even if it could be called only partial in many respects – was roughly completed by 1949, and production reached half of the last peace year before the war.

In 1948, all industrial and larger agricultural distilleries were nationalized. The Distillery Directorate was abolished and on January 1, 1949, the distilleries, which had been organized into independent national companies, were transferred from the Ministry of Finance to the Ministry of Light Industry and then to the Ministry of Food Industry. In the early 1960s, companies with similar profiles were merged into a large corporation. Thus, in 1963, the Győr Distillery became the Győr factory unit of the National Distillery Company. In the 1970s, numerous companies in the region dealing with the production of spirits, beverage preparation and distribution were annexed to Győr, which from then on continued to operate as members of the large national corporation, which had in the meantime been organized into a trust under the name of Győr Distillery Company. From then on, in addition to fine spirits, they also produced alcoholic and non-alcoholic beverages.

The distillery around 1955

source: https://moderngyor.com/2014/07/27/a-gyori-szeszgyar-bovitese/#jp-carousel-4000

In the 1950s and the first half of the 1960s, production was carried out under great difficulties. Due to the post-war supply difficulties, the use of grain or sugar beets as raw materials was out of the question for more than a decade. Molasses became the exclusive raw material for industrial alcohol production, so alcohol production became a function of sugar production.

In 1958, the third post-war reconstruction plan of the distillery was completed, the main objectives of which – the elimination of bottlenecks and the implementation of safe production – had already been realized. The boilers were modernized, the factory’s own electricity generation equipment was restarted, outdated tanks and fermentation vats were replaced, and a new artesian well was drilled. The reconstruction ensured adequate steam and water supply for decades, drinking water for fermentation, and the necessary industrial water for cooling, as a result of which all specific indicators of production improved dramatically.

The spread of intensive, industrial animal husbandry systems in Hungary created an increasing demand for proteins used in compound feeds. In the 1960s, various experiments were carried out to replace the protein from capital imports with domestic production. One promising way was to utilize the yeast (torula yeast) produced during the production of alcohol. The country's first industrial-scale torula yeast factory was built in Győr in the mid-1960s. Protein-producing microbes were propagated in huge tanks on molasses liquor, which were selected by centrifugation and then dried, thus obtaining dried feed yeast with a 50% protein content that was easy to store and handle.

After the start-up of the torula plant, the burning of slag coal in Győr ceased, but the molasses slag still contained a lot of organic matter after torula treatment, which was then released into the Danube untreated.

Spirit and molasses storage tanks

The aim of the new large-scale reconstruction carried out in the 1970s was to create a production capacity that would allow the full processing of the increased amount of sugar factory by-products, and thus not only could they stop importing refined alcohol from capitalist countries, but they could also export alcohol for convertible currency. The old coal-fired boilers were replaced with hydrocarbon-fired boilers and a new distillery was purchased. Finally, they stopped producing feed yeast and switched to producing vinasse, a by-product that is easily utilized by ruminants and is still liquid, obtained by thickening molasses, which was successful in eliminating the severe pollution of the Danube.

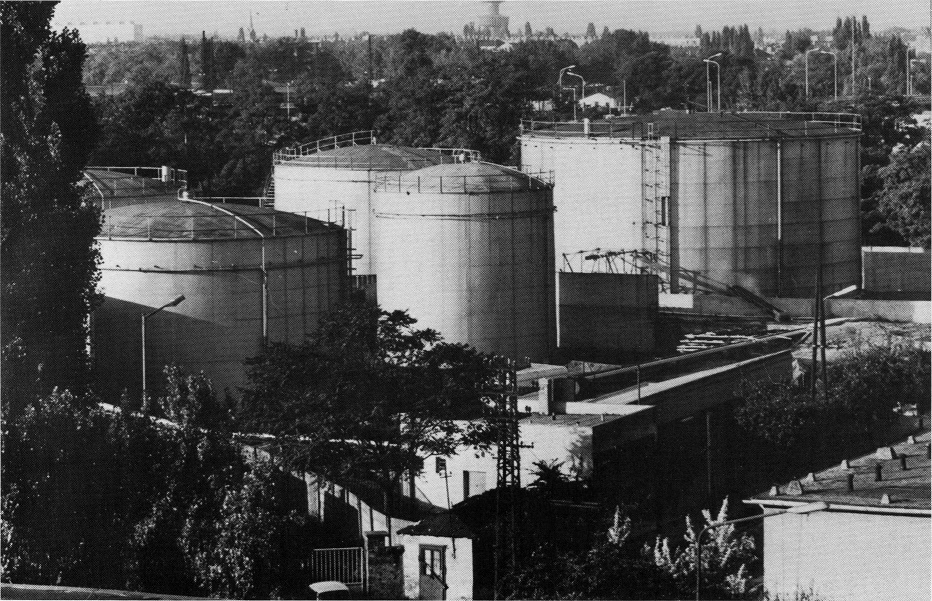

Factory view 1976

The sleek, modern, all-glass new brewing and refining building, slightly taller than the old one, was built in the immediate vicinity of the old building, housing the energy-saving equipment capable of distilling 32,000 tons of spirits per year.

The new cooking and refining building completed in 1971

Photo: Zsolt Andorka

The large-scale corporate organizational framework that had developed in the early 1960s disintegrated in the mid-1980s. In 1984, the Distillery Companies Trust was dissolved and the Győr factory regained its independence.

The factory yard, with the feed yeast plant in the background

Today, there is only one sugar factory operating in Hungary, so the Győr distillery imports the molasses it needs for production from increasingly distant sources, including Austria and Slovakia, as well as Ukraine and Poland. The by-product of distilling, vinasse, is hardly used for animal feed anymore. More recently, it has been used in neighboring countries to produce biogas, and some of it is used to fertilize the soil.

The half a decade after the change of regime – unlike many other Hungarian industrial companies – saw the Győr distillery in good condition, and it was one of the best periods of the Győr Distillery. The transition to a market economy brought great prosperity to the Hungarian distillery, with the output of spirits tripling. The factory, equipped with modern Finnish and American equipment, was in working order, and the new owners inherited a well-equipped and well-run company.

The factory sold more than 80% of its refined spirit to Switzerland, Poland, Italy, Austria, Slovenia and Slovakia during this period. The production of feed yeast was completely stopped, thus eliminating the noise and odor pollution that was most disturbing to the surrounding population. The old cooking and refining plant is no longer in operation, although some of the equipment remains in the building. Spirit is produced exclusively with the new energy-saving Finnish equipment. The dehydration of the spirit has also been stopped, because they cannot compete with the huge capacity bio-standard factories built in the region.

In recent years, the relocation of the factory has been discussed. Today, the large neighbor, the wagon factory, no longer exists, and the factory, which sometimes emits unpleasant odors during operation, is slowly being surrounded by residential buildings. It is therefore not in a good location, and on the other hand, the raw materials have to be transported from a distance. The relocation and relocation of the factory is not on the agenda today, it will remain in its original location for the time being. At the same time, the company is committed to minimizing noise and odor pollution, even at the cost of considerable costs.

In 1993, Győri Szesz és Italgyártó Rt. was established with 543,801 million forints, which after a short operation split into two independent companies on January 1, 1994, namely Győri Szeszgyár és Finomító Rt. , which deals with alcohol production, and Győri Likőrgyár Rt., which deals with beverage production.

The buildings of the Győr Liquor Distillery Co. on Budai Street

Photo: Zsolt Andorka

In 1992, after the change of regime, the new CEO of the Győr Distillery was György Folláth, who – together with several family members and other Hungarian investors – owned the controlling stake in the factory. After his death, his wife and two sons inherited the company.

The compilation was based on the study of Dr. János Honvári.

Continue to the detailed study

The images with unmarked sources come from the book János Honvári: A History of Small Hungarian Industry, the History of the Győr Distillery.

| INTERESTING FACTS |

|

Ágoston Lederer graduated from a chemical vocational school in his youth and gained theoretical and practical experience in organizing and managing large modern capitalist companies in many foreign countries. Blessed with an excellent economic sense and great organizational skills, he founded a number of significant companies in the Austro-Hungarian Monarchy and beyond. In addition to wagon and machine manufacturing, he was involved in a number of distilleries, refineries and starch factories. He is also credited with founding the Hungarian Wagon and Machine Factory, the largest factory in Győr for more than a century. Lederer's new factory foundations in Győr were aimed at smoothing out the difficult-to-predict conjunctures of the distillery business to some extent. His most significant undertaking – which had a far-reaching impact on the further economic life of Győr – was the establishment of the Győr wagon factory in 1896. At the start, the wagon factory's direct connection with the Győr Distillery – and its owners – was quite tangible. The application to the city council announcing the foundation of the wagon factory was signed "Győr Distillery and Refining Co.". The first buildings for the wagon factory were the empty stables of the distillery, which had been unused for years. The wagon factory used the electricity from the distillery's electric power plant, and the distillery was also one of the wagon factory's very first customers, when it ordered 9 railway tank cars from the wagon factory. Distillery tanker (Győr, Rába Company Museum) Additional information for the biography: Győr szab. kir. vilasi és Győr-Moson-Pozsony kee köyei köjek. Ed. Palatinus József, Henrik Lőwenthal was the managing director of the factory from 1912. Győr szab. kir. vilasi és Győr-Moson-Pozsony kee köyei köjek. Ed. Palatinus József, |

|

The noisy and smelly feed yeast plant caused a lot of inconvenience to the people living nearby in Győr and its operation was not smooth either. The yeast often caught fire in the dryer, and feed dust was released into the air, which could not be completely eliminated even by installing a wet dust collector. The biggest problem, however, was that from then on, the Győr Distillery, located next to the city's sewer system - Győr did not yet have a sewage treatment plant, so 70,000 cubic meters of sewage flowed untreated into the Mosoni-Danube every day - became one of the biggest polluters of the Mosoni-Danube. As long as they produced slag coal, the by-product of the distillery production did not enter the river in the Great Plain. |

| LITERATURE |

- 1997. Győr Distillery and Refinery Limited Liability Company. Founded in 1884. Photo: László Klausz, Zoltán Alexay. Description. 16 pages.

- 1995. János Honvári: A short history of Hungarian industry, the history of the Győr distillery. 2nd ed. Glória Publishing House, 315 pages.

- Győr Distillery and Refinery Co. Ltd. website: http://www.gyoriszesz.hu/company_history_hu.html

- Győri Liquor Distillery Ltd. website: https://www.gyorilikor.hu/rolunk_4

The images published without source come from János Honvári's volume: A Short History of Hungarian Industry, the History of the Győr Distillery, published in 1995.

Related gallery

Back to the previous page!