Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Grab M. Sons Leather, Waxed Canvas and Linoleum Flooring Factory

| ADRESS OF THE MEMORIAL SITE, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL SITE? |

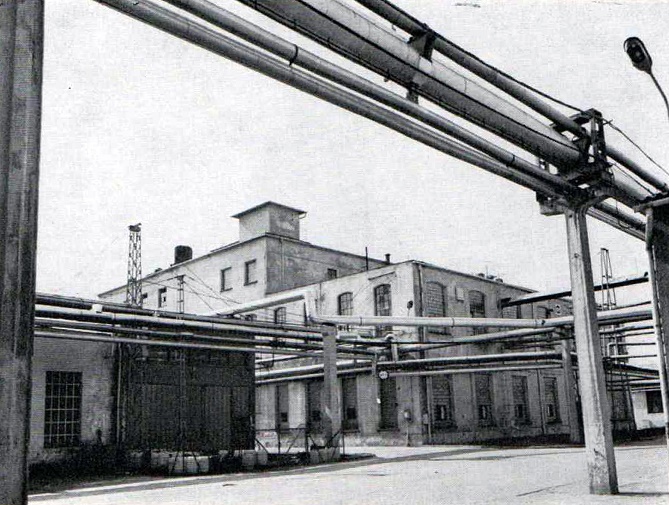

The memorial plaque is located in front of the Graboplast office building, in a green area surrounded by the sidewalk and the bicycle path. Several of the buildings on the site of the former Graab factory still survive today, although they are not clearly visible from the street front.

Graboplast today. Aerial photo: Zsolt Andorka (2018)

Looking through the gate next to the office building, we see the two-story former main building with its clock tower staircase. To the left of it, a brick factory chimney from the founding period rises.

Fotó: Andorka Zsolt (2018)

Photo: Zsolt Andorka (2018)

Heading towards Körkemence Street, the “board of directors’ residence” stands in a closed landscaped area directly in front of the SPAR parking lot . This area no longer belongs to Graboplast.

An old production facility can be viewed on the ground floor of the current office building.

The machine on display in the auditorium. Photo: Zsolt Andorka (2018)

With prior registration, groups can visit the factory history exhibition .

Street View:

Tudta-

| BRIEF OVERVIEW |

|

Dr. Hugó Graab and Emánuel Graab applied for permission to build an oilcloth and linoleum factory in Győr in the autumn of 1903. Production started in 1906 , and a year later they were also producing artificial leather in Győr. In 1923, they founded the Graab Textile Co. Ltd. with a co-entrepreneur. After nationalization, it continued its activities under the name of the First Hungarian Oilcloth and Artificial Leather Factory, and from 1950 onwards under the name of the Győri Cotton Weaving and Artificial Leather Factory. The name Graboplast Műbőrgyár was adopted in 1969, which also became a brand name. Under the leadership of Péter Jancsó, the director elected in 1986, the emphasis was placed on the production of wallpaper and artificial flooring; the main profile of Graboplast Textil és Műbőrgyártó Rt., founded in February 1990, became the production of interior covering and decorative materials. In 1995, they purchased the majority ownership of Keszta-Dunawall Kft., 90 percent of the Sopron Carpet Factory, and 100 percent of the Győr Uniontext Textilipari Kft. This made it possible to modernize the floor production and launch the new wallpaper project. They acquired 88% of the Kecskeméti Parkettagyártó Kft. On July 1, 1997, they merged the Kesztölc Tapetagyártó Kft. and the Győr Grabo Kft., and wallpaper production and sales began under the name Grabetta-Keszta Kft. Grabofloor Ltd. was founded in Tatabánya in November 1997 with production lines suitable for 4-meter floors. The company has been operating in a holding model since January 1, 1996 . The company employs 650 people in its four plants in Győr, Kecskemét and Tatabánya. Graboplast Flooring Manufacturing Co. Ltd. is the leading specialist flooring manufacturer in Central Europe, and the basic principle of its strategy is constant growth and increased competitiveness, meeting EU requirements and global market challenges. |

| DETAILED COMPANY HISTORY |

The factory is one of the few companies in Győr that has been operating continuously in the city since its founding. The company has undergone numerous transformations over its more than 110 years of existence, and the changes in its name reflect this.

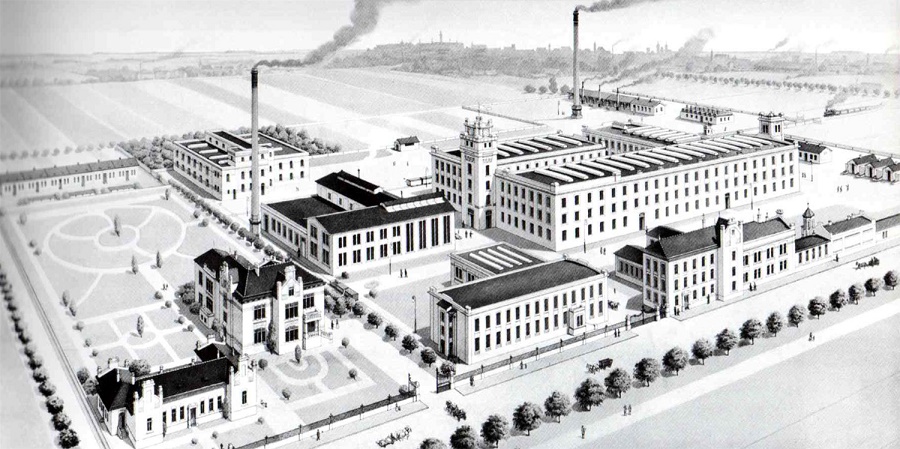

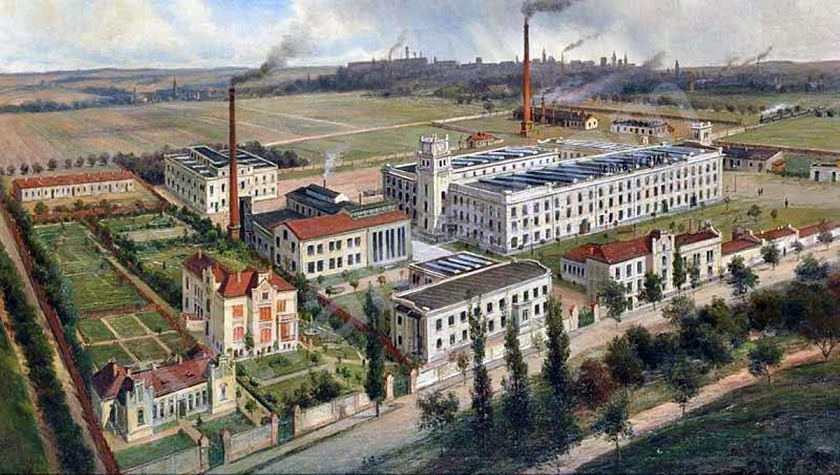

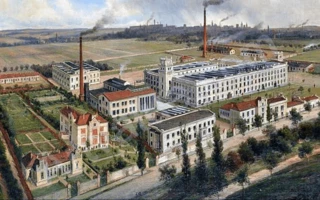

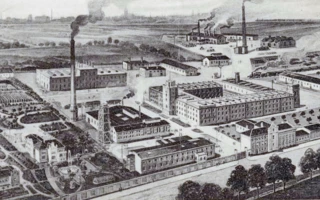

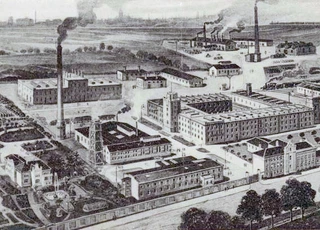

The factory around 1905

Source: Győr County. Edited by Borovszky Samu. Budapest, 1910

http://mek.oszk.hu/09500/09536/html/0009/9.html

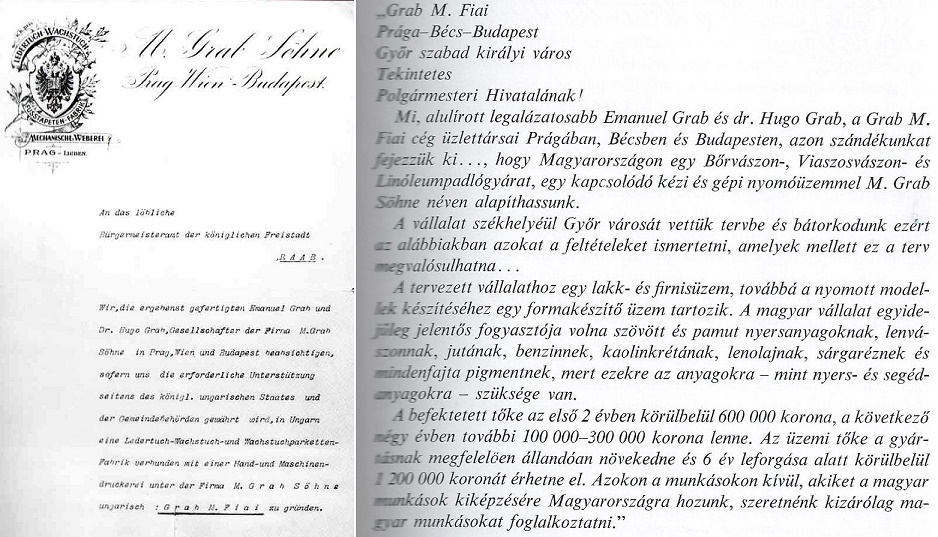

In the early 1900s, the Grab family had significant business interests in Prague, Lieben near Prague, Vienna and Budapest. Czech capitalists consider a letter from Károly Zechmeister to the mayor of Győr, dated November 30, 1903, to be the first written document of artificial leather production in Hungary.

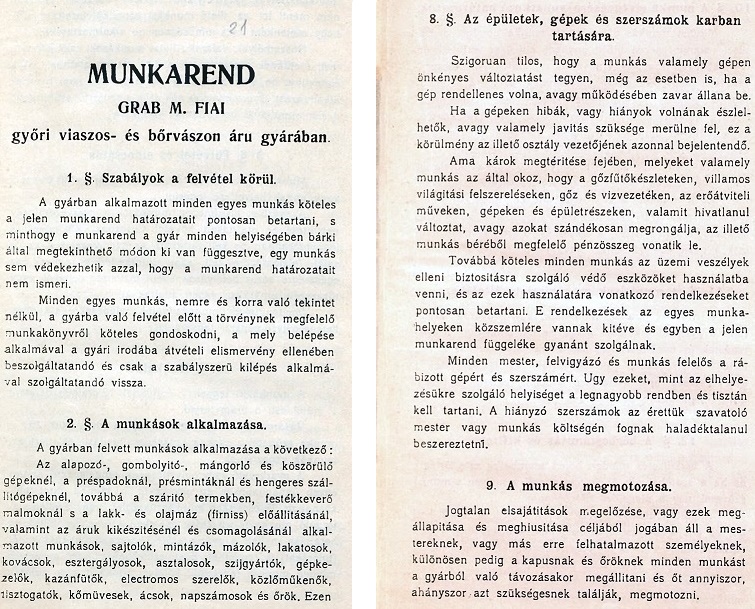

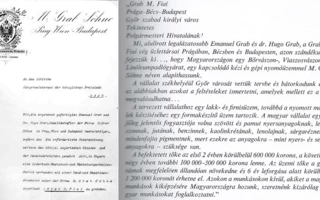

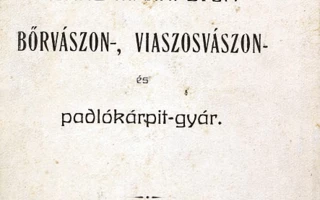

The first page of the founding document and the translation of the document

On January 21, 1904, the city of Győr gave its consent to the establishment of the factory, which was conditional, according to which the factory must be put into operation by the end of 1905 at the latest, which includes a factory producing leather canvas, wax canvas and wax canvas parquet, as well as a manual and mechanical printing plant; the owners must invest at least 600,000 crowns in the enterprise, and they can only produce wax products and their by-products for 15 years.

Only the Viennese textile manufacturer Gyula Leon filed an appeal against the intention to establish a factory. The owner of the Magyar Mechán Cotton and Woolen Goods Factory, which was already operating in Győr, feared that the new factory would create competition on the labor market. The Minister of Trade considered the petition unfounded, and the Czech capitalists also received a financial contribution from the Minister, worth about 250,000 crowns, to start their business. The industrial establishment program of the mayor of Győr was in line with the government's industrial development policy, thanks to which additional industrial companies could be established in the city after the turn of the century.

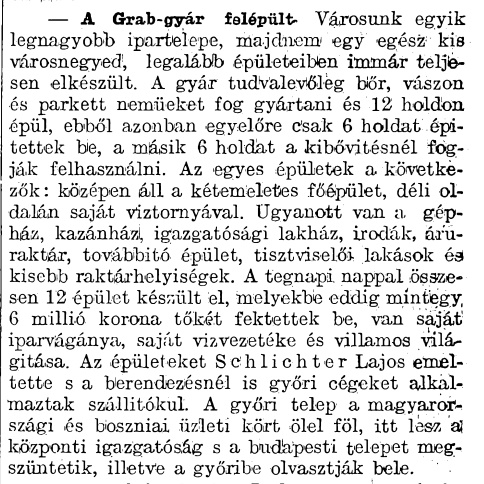

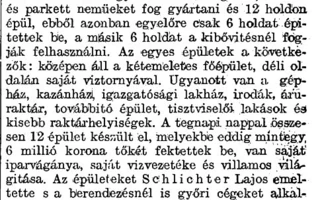

The owners entrusted the well-known Győr bricklayer, Lajos Schlichter, with the execution of the construction works, who at that time already had a construction company employing several hundred workers. A significant part of the machinery came from England. An enthusiastic article in the local press informed the city's public about the start of the works.

The factory buildings were completed by November 11, 1905 , and partial trial production could begin that year, but the complete equipment did not arrive until the middle of the following year, and all production equipment was operational from the second half of 1906.

Győri Hírlap, November 12, 1905, No. 265, p. 5.

Source: http://edok.gyorikonyvtar.hu/

The owners wanted to further develop the production that had started under favorable market conditions in 1907, and in their application to the mayor of Győr they requested an investment permit for the production of nitrocellulose-based artificial leather. In order to establish a grabiol plant with a high fire and explosion hazard, the approval of the city administration and the permission of the police chief were required, which required the establishment of a strict fire safety system.

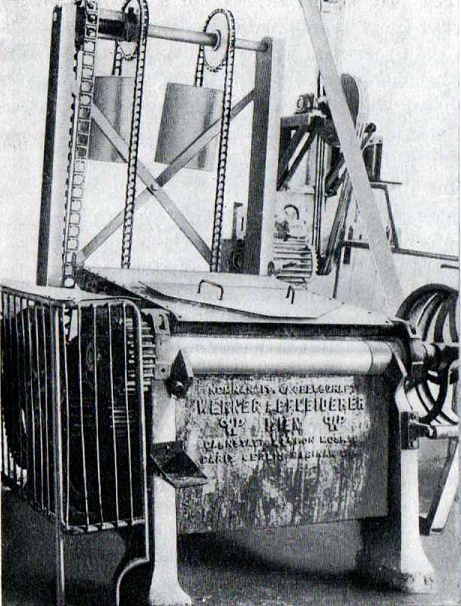

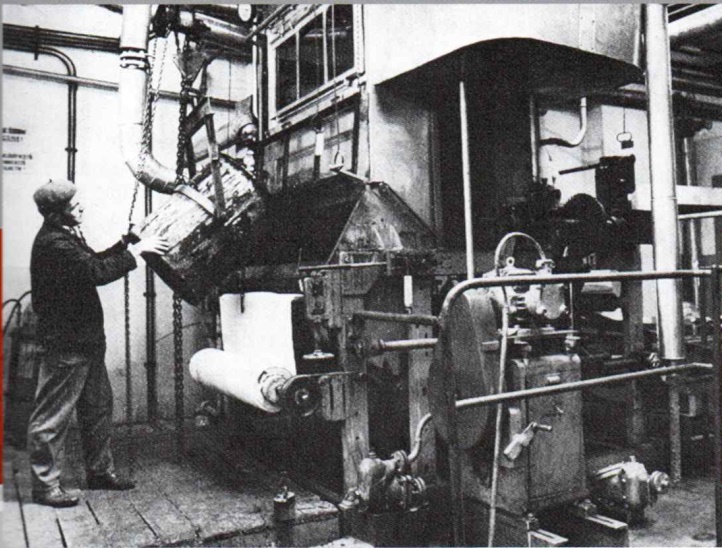

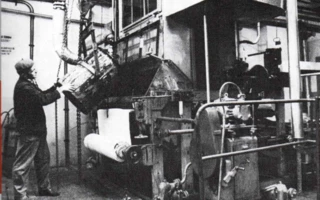

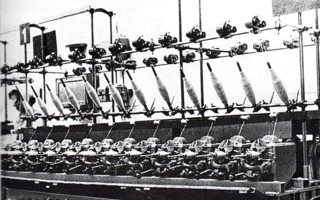

Grabio plant mixer

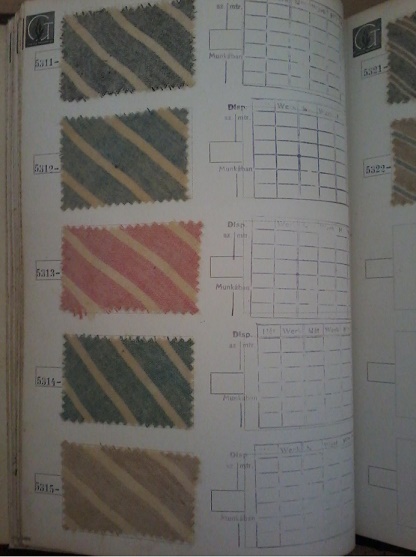

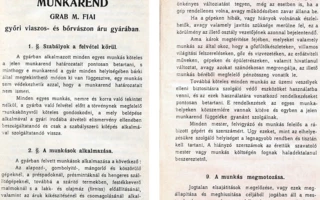

Excerpt from the work schedule of the Grab. M. Fiai Győr Leather, Waxed Canvas and Upholstery Factory published in Győr in 1907

Source: http://edok.gyorikonyvtar.hu/?docId=58250

Colored postcard, depiction before 1910

Source: https://regigyor.hu/vegyes/gyor-gyaripara-1905/

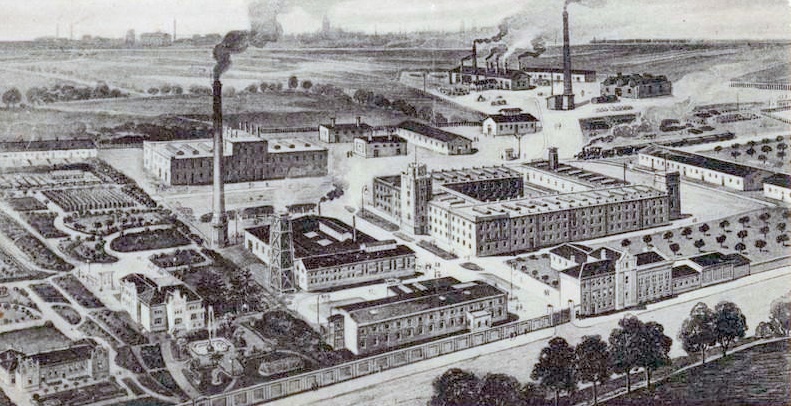

Győr. Postcard with the inscription Grab M. Fiai from the 1910s

Source: http://pctrs.network.hu/clubpicture/1/1/1/_/gyor_1910_grab_gyar_1011051_3321.jpg

By 1912, the company's main profile had become the production of nitro artificial leather, so the owners sold the linseed oil-based production technology with exclusive production rights to Ede Keffel, an entrepreneur from Leipzig and operating in Győr, who based his production on this technology and established his factory next to the Grab factory.

The war preparations provided the factory with significant state orders and increasing profits. The production of traditional products was increasingly replaced by the production of tent sheets, chemical and raincoats, car covers, and military backpacks. In the summer of 1914, the company was declared a war plant.

Győri Hírlap, August 3, 1916. 176. az. p. 3.

Source: http://edok.gyorikonyvtar.hu/

Toe dipping machine, used to make shoe toe stiffeners during the nitro leather production period

In 1920, the factory aimed to satisfy the needs of the citizens with its products. In order to ensure a smooth supply of textile raw materials, the Grab M. and Sons company founded the Grab Textile Industry Co. Ltd. in 1923 with the wholesalers Teltsch Arnold and Rudó István from Győr - the Teltsch A. and Co. company also had a hand loom . The new textile factory was built on the premises of the Grab factory.

During this period, they also tried to make faux leather products for the fashion industry. The fashion show promoting Grab faux leather was a great success, but faux leather had not yet become a staple in the clothing industry.

Grab collection made of artificial leather, press photo from the 1925 fashion show

Source: Free Royal City and County of Győr. Budapest, 1926. p. 20.

In 1936 , Grab Emanuel died, and in the same year the Grab family left the joint-stock company, so the factories founded by Grab M. and Sons continued to operate as the property of the Grab Textile Company , under the management of Teltsch Arnold. As a result of the new war preparations, the factory began to switch back to the production of military and military equipment.

Product sample production catalog from the 1930s

In the 1940s, the company's factories produced raw, dyed and finished variegated cotton goods and nitro artificial leather. The cotton weaving factory's product range included molino, poplin, mull, various flannel materials, and handkerchief materials. The vertical was complete from yarn production to finished goods. The other factory's Grabiol factories produced various artificial leathers, handicraft materials, shoe linings, shoe toe stiffeners, hemming tapes, and bookbinding canvas. They also produced artificial leathers for the roof of car bodies and baby carriage canvases.

The factory's grab operation

During World War II, the company operated as a war factory. The bombings caused relatively little damage, so production began in the spring of 1945. The factory exported flannel and regularly supplied it to the domestic market.

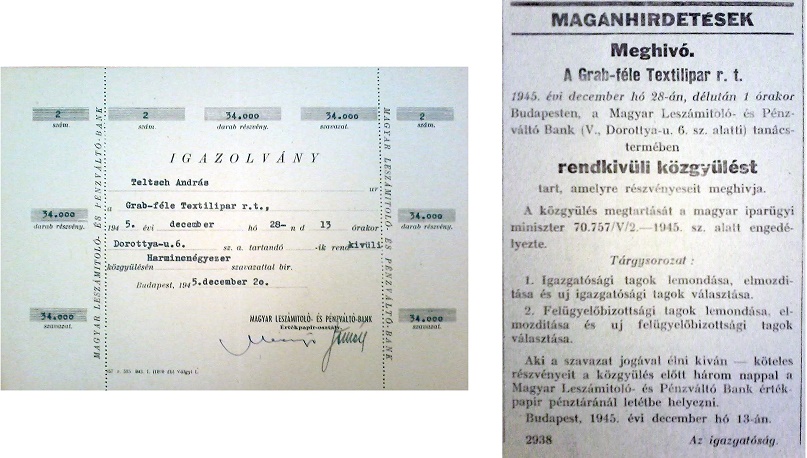

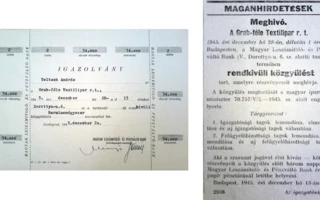

Invitation and share certificate for the general meeting of Grab's Textile Industry Co., Ltd. to be held on December 28, 1945

After nationalization, the company continued its activities under the name of the First Hungarian Waxed Canvas and Faux Leather Factory, and after the reunification of the former Grab factories, from 1950 onwards it continued its activities under the name of the Győri Cotton Weaving and Faux Leather Factory. Nándor Jankovich took over the factory in 1957, and he placed the main emphasis on the production of faux leather. He had his own research laboratory set up so that new products could be introduced to the market as soon as possible.

The first major investment began in 1958, when they purchased a synthetic leather production line that performed the lubrication, pressing and heat treatment operations alone. This marked the beginning of PVC-based synthetic leather production.

Source: http://edok.gyorikonyvtar.hu/

The company expanded its product range with foam-structured artificial leather, breathable artificial leather and a family of automotive floor coverings. These developments led to a large and continuous order from the Fiat car manufacturer for products used in car seats.

The Grabona brand name has been used since 1966, the name referring to the founder. The name Graboplast was adopted in 1969 , which also became a brand name.

The Sopron indoor swimming pool

The plastic tent developed at Graboplast was maintained by the air pressure created in the pool area.

Source: http://egykor.hu/sopron/fedett-uszoda/1103

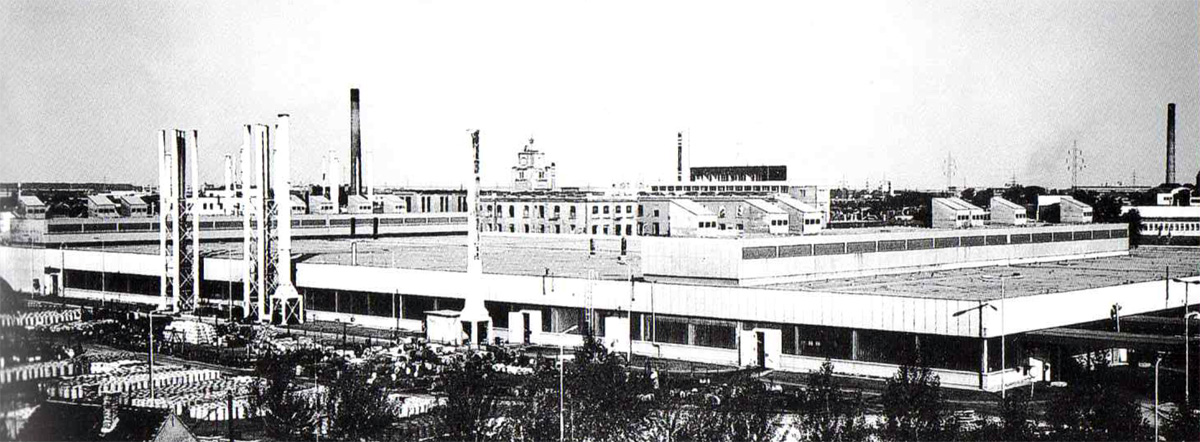

During the years of major investment , between 1969 and 1972, the new artificial leather factory and finishing plant were established.

Graboplast's main hall

The company's own research and development department also received significant support. One of the company's own developments is a non-woven fabric, the non-woven artificial leather substrate, the vlies (artificial felt).

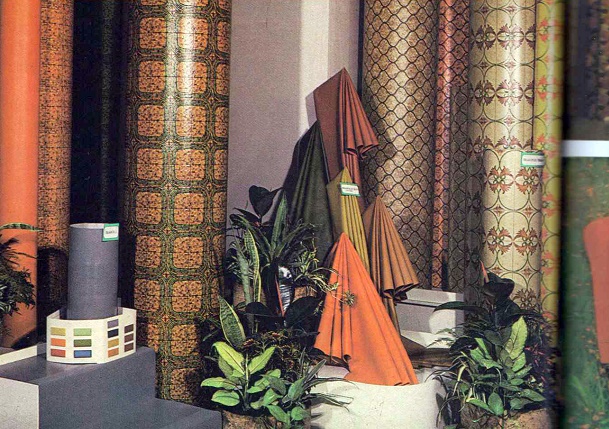

Floor coverings with smooth and patterned surfaces at an exhibition in the late 1970s

The Company Council elected Péter Jancsó as director in 1986, after the retirement of Nándor Jankovich.

In 1988, companies were founded, creating the Grabo Group of Companies . In 1989, independent foreign trade began. During the transformation into a joint-stock company, the company's financial partner was Bank Austria Creditanstalt. Graboplast Textil és Műbőrgyártó Reszvénytársaság was founded on February 20, 1990 with a 30% foreign share. From 1990, the company's main profile became the production of interior covering and decoration materials.

Artificial leather production

At the end of 1993, the State Property Agency sold the shares it owned, 58 percent of Graboplast's shares, to investors. In 1994, the company was listed on the stock exchange. Graboplast's share capital was 2 billion 332.5 million HUF. Foreign financial investors acquired a 30% ownership stake. The price of Graboplast's shares fluctuated around 1000 HUF in February 1995, in June the shares were sold at a price of around 1300–1400 HUF, and in September at a price between 1700–1800 HUF. The dynamic growth was supported by corporate acquisitions : in April 1995, the general meeting approved the purchase of 90 percent of the Sopron Carpet Factory, 100 percent of the Győr Uniontext Textilipari Kft., and the majority ownership of Keszta-Dunawall Kft. This made it possible to modernize the floor production and launch the new wallpaper project. They also acquired 88% of Kecskeméti Parkettagyártó Kft., which has a share capital of 240 million forints.

The company has been operating in a holding model since January 1, 1996. Grabo Kft. was founded. In the new structure, Graboplast Rt., with a share capital of 3.2 billion HUF, became the controlling company, with Péter Jancsó as the CEO. The joint-stock company produced 55 percent of the wallpaper production in the country.

On July 1, 1997, Kesztölc Tapetagyártó Kft. and Győri Grabo Kft. merged, and wallpaper production and sales began under the name Grabetta-Keszta Kft.

Komárom-Esztergom County 24 Hours, 1997. Mar. 20. No. 66. p. 7.

Source: https://library.hungaricana.hu/hu/

In Slovenia, Savainvest Business Consulting, Investment and Management Ltd. was established with a share capital of 1.5 million tolars. In 1977, Graboplast shares were listed on the Luxembourg Stock Exchange. Global Depositary Receipt (GDR) trading was launched.

In Tatabánya, in November 1997, Grabofloor Kft . was founded with a share capital of 350 million HUF to create a plant suitable for the production of 4-meter floors.

Tatabánya, Grabofloor Ltd. 2000

In addition to Graboplast's world-class PVC flooring factory in Tatabánya, built in 1998, the company also built a new Grabo Design Flooring Factory in 2016.

Grabo Design Floor Factory 2016

In addition to traditional PVC flooring production, LVT (Luxury Vinyl Tile) and non-directional homogeneous floor coverings produced with completely new technology are manufactured in Tatabánya.

They adapted to the changes in the world market by further restructuring the product structure. In September 2000, the new strip parquet plant was completed in Kecskemét with a greenfield investment of 1.5 billion HUF.

Petőfi's People, Bács-Kiskun and South Pest County Edition, May 25, 2001, No. 121, p. 5.

Source: https://library.hungaricana.hu/hu/

Wallis Investment Co. acquired 25.1% of Graboplast's shares in December 2000. The majority owner reappointed Péter Jancsó as CEO for another six years. Uniontex Textilipari Kft. was sold that same year.

Graboplast went public in 2001. The company, which sells 93% of its production on foreign markets, owes its recent successes to the growing demand for floor covering products.

In 2004, the Sopron Carpet Factory was sold, and non-woven production was stopped. The company practically ceased textile production, and from the fall of 2004 its profile became flooring production, which is also reflected in the new name: Graboplast Flooring Manufacturer Ltd. In 2006, the group of companies was merged; the subsidiaries - Grabo Kft, Grabofloor Kft, Graboparkett Kft, Gif Kft - merged into Graboplast Zrt.

In 2014–15, Graboplast received a new, unique image. In twenty years, the company has transformed from an artificial leather factory into a flooring manufacturer. The company's activities include the production and sale of residential, public, sports, automotive and show flooring, as well as wall coverings, artificial leather and parquet. In 2018, Graboplast is working on the development of self-disinfecting and self-cleaning, wear-resistant, flexible surface flooring. The company employs 650 people in its plants in Győr, Kecskemét and Tatabánya. The basic principle of Graboplast Flooring Manufacturing Co. Ltd.'s corporate strategy is constant growth and increasing competitiveness, continuous compliance with EU requirements and global market challenges.

The compilation is based on the study of Mrs. Orbánné Dr. Márta Horváth and the books N. Magyar Tibor: Artificial Leather Production in Hungary (1905–1980) and 100 Years in Motion. Graboplast.

| INTERESTING FACTS |

|

Why did entrepreneurs want to switch to the production of nitrocellulose-based artificial leather? Artificial leather was developed to replace the much more expensive real (animal) leather, it is an industrially produced product that is designed to look similar to natural leather. It can be made partially or completely of plastic. We distinguish between artificial leather with or without a carrier. The base of artificial leather with a carrier can be textile (fabric, knitted fabric, felt, etc.) or paper, the task of which is to ensure dimensional stability and strength. The plastic layer is applied to this base. In artificial leather without a carrier, the artificial leather layer is not applied to a base, but is formed independently as a flexible plastic sheet. These are foil artificial leathers. |

|

Linoleum was first produced in England in 1863. After drying, the fabric was impregnated with a mixture of linseed oil and pine resin enriched with cork flour, and became a hard-surfaced but flexible sheet, which was sold in large rolls. Waxed cloth is a fabric coated with linseed oil. Linseed oil coating was later replaced by nitrocellulose, which opened up the possibility of producing products of various colors and patterns. It is still used as a kitchen tablecloth today due to its waterproof properties and easy cleaning.

|

|

The history of today's manufactured artificial leather began with the use of polyvinyl chloride (PVC) as a lubricant. The development of large-scale production of PVC, invented in 1838, and the production of soft PVC that could be used for artificial leather production occurred much later, in 1934, thanks to the developers at the BASF chemical factory. More information: https://mubor.hu/a-muborgyartas-kezdetei/ |

|

Name variations: Grab M. and sons 1905– Grab M. and Sons Leather, Waxed Canvas and Floor Upholstery Factory 1906– Grab's Textile Industry Co. Ltd. 1923– First Hungarian Waxed Canvas and Artificial Leather Factory 1948– Győr Cotton Weaving and Artificial Leather Factory 1950– Graboplast Artificial Leather Factory 1969– Graboplast Textile and Artificial Leather Manufacturing Co. 1990– Graboplast Rt. Holding 1996– Graboplast Flooring Manufacturer Ltd. November 2004– Graboplast Flooring Manufacturing Co., Ltd. 2009– |

| LITERATURE, REFERENCES |

- 1980. N. Magyar Tibor: Artificial Leather Production in Hungary (1905-1980). Budapest, Academic Publishing House. 201 pages.

- 2005. 100 years in motion. Graboplast. Edited by Ferenc Hajba, Zsuzsa Maróti, Ágnes Mónus. Photo: Miklós Katona, Károly Matusz. Győr, AdArt Studio. 65 pages.

- 2014. Orbánné Márta Horváth: The transformation of the textile industry in Győr from 1985 to the present day (in: From Grábgyártól to Grabolast Zrt. p. 165-168. In: Driving forces of Győr's development. Monographs of the research on the Győr automotive industry district as a new direction and tool for regional development 1. Editor: János Honvári. Published by: Universitas-Győr Nonprofit Kft. Győr. p. 158-178.

Image source:

- N. Magyar Tibor: Artificial Leather Manufacturing in Hungary. 1905-1980. Archive photos from the book, as well as photos by Miklós Katona and Béla Soproni Jr.

- Archive photos from the book "100 years in motion. Graboplast.", as well as photos by Miklós Katona and Károly Matusz.

- MNL Győr-Moson-Sopron County Győr Letter Grab's Textile Industry Co. (1905-1946) Co.'s documents (XI.9.)

Additional source:

https://www.graboplast.com/index.php?lang=hu

Related gallery

Back to the previous page!