Contact details

Foundation for Industrial History of Győr

Szent István út 10/a

Phone:

+3696520274

Fax: +3696520291

E-mail:

ipartortenet@ipartortenet.hu

Map

Bakery Company

CERES BAKERY INDUSTRY CO., LTD. (GYŐR BAKERY FACTORY)

| Address of the memorial site, route planning | ||

| What can we see at the memorial site? | ||

| Brief overview | ||

| Detailed company history | ||

| Interesting facts | ||

| Literature, references | ||

| Next stop of the first round trip |

| MEMORIAL SITE ADDRESS, ROUTE PLANNING |

| WHAT CAN WE SEE AT THE MEMORIAL? |

Street View:

-

Photo from our days:

Photo: Zsolt Andorka, 2023

| BRIEF OVERVIEW |

|

The predecessor of the Győr bread factory, which has undergone numerous changes of ownership, was founded by the Ministry of Food Industry from the Győr-Sopron County Bread Factory on October 21, 1953. The colloquial language referred to the company at the time as the “Győr Bread Factory”, although at that time we could not yet speak of industrial production. Bread and baked goods were made in the traditional way – in paddle-fired ovens – in factories operating in various parts of the city. By the 1960s, it became obvious that the existing production capacities could not supply the population of the city and its surrounding area with quality baked goods. In 1964, a mechanized bread factory, built next to the cold store and the Industrial Canal, was put into trial operation, and at that time it was the largest in the country. Over the years, the company has continuously expanded and modernized the factory in accordance with changing market demands. In 2000, Ceres Sütőipari Kft. began construction of a new bread factory on the site, in the free space available in front of the existing building, with a “greenfield” investment of nearly 1 billion forints. The facility housed the company’s first Dutch toast line. Ceres Zrt. is today the largest domestic manufacturer of pre-packaged, sliced toast bread, with significant export activity.

|

| DETAILED COMPANY HISTORY |

THE DEVELOPMENT OF THE BAKERY INDUSTRY, ITS BEGINNINGS IN GYŐR

Győr plans for solving the problem of official bread production and establishing village bread factories

The city government of Győr considered the provision of public needs as an important task in the early 1910s, so it also wanted to provide the population with adequate quantity and quality of bread. The newspapers of the time reported on the city bread factory several times, and in 1912 the Városok Lapja published in detail the study compiled with the participation of Mayor Jenő Wennes, Councilor Géza Éberth and Chief Engineer Ferenc Erdély on the necessity of the Municipal Bread Factories and the plan for establishing the Győr bread factory.

The issue of establishing a bread factory in Győr was on the agenda until April 1916, when the Győr city council announced a tender for the construction of a city bread factory and a bread factory residential building, but no decision was made due to the wartime economic conditions.

Between the two world wars, the possibility of building a bread factory arose once again, but the city council removed the issue from the agenda, citing uncertain economic conditions.

History of the foundation

After World War II, the organized supply of bread to the city's residents was restarted on the ruins of the remaining private bakeries. These were called community bakeries.

The Győr County Newspaper, in its December 4, 1949 issue, reports optimistically on the successes of restoring the bread supply:

“Eight Municipal Bakeries recently opened in our city. Having overcome the initial difficulties, today we are at a point where the city’s bread supply is completely smooth and impeccable in terms of both quantity and quality. Initially, the difficulty was that there were disruptions in the flour supply to the bakeries, and the flour delivered did not reach the desired level. …

Of the Communal Bakery Plants , the one opened in Gorkij-telep is of particular importance, as it provides bread for the entire working-class neighborhood . Our Communal Enterprises were established in the interests of the workers. Our workers have become friends with them, because they see that the employees of the enterprises work for them.”

7 catering companies, 15 meat factories, 8 bakery village companies for the workers of Győr.

Győrmegyei Hírlap, 1949. Dec. 4. No. 282. p. 11.

The Executive Committee of the Győr City Council regularly kept the issue of bread supply for the city and its surroundings on the agenda at its meetings. At the council meeting held on September 8, 1950, it discussed issues related to the operation of the Municipal Bread Factory, which had been operating for a year.

Instead of the name "Community Bakery", the definition "Community Bread Factory" is included in the minutes, although we cannot actually talk about bread factories yet, only about baking factories.

According to director Antal Szabó, the company closed the second quarter with a profit after introducing performance-based wages and piecework wages. If they received more fine flour for the production of pastries, they could produce a higher profit, because this is the only product that benefits the company. According to one of the members of the World Trade Organization, the Municipal Company cannot ensure the bread supply of the city of Győr because the private bakers have been laid off and cannot take on overtime. He suggests that four baker's assistants be brought in from the Wagon Factory, with whom they can start the fourth bakery.

At its meeting on September 15, 1950, the Executive Committee of the Győr City Council – on the instructions of the Ministry of the Interior and the Executive Committee of the Győr-Sopron County Council – founded a bread factory in Győr.

"Name: Győri Bread Factory, seat : Győr.

The company's purpose: practicing the baking industry, performing all kinds of industrial and commercial activities within the scope of the baking industry.

The company's governing body: the City Council."

Despite the name of the bread factory, there was no industrial production. A handwritten note in the minutes reflects the labor situation in the profession at the time: 60% of the bakers were 60–70 years old, baking with their wives.

The statements of the World Cup members regarding the bread factory reflect the nationalization efforts of the national policy: “…there is a decree that the private sector must be liquidated in all professions by the end of the year. There are still 34 independent bakers in Győr, they should also be taken over by the bread factory.” Another comment: “We will review the equipment of the existing 34 private bakeries and set up the appropriate ones with 2-shift operation. We will take over the private bakers as employees of the bread factory.”

At the meeting of the City Council held on October 31, 1952, they urged the establishment of a new bakery, since the bakery taken over by the bread factory was not suitable for a larger operating load in its current condition. They proposed the purchase of a kneading machine and other equipment worth 35,000 forints, and the purchase of a used bread transport wagon, tarpaulin, horse and horse tools for 10,500 forints.

Renaming of the Győr Bread Factory to the Győr-Sopron County Bakery Company

At its meeting on December 17, 1952, the Executive Committee of the Győr-Sopron County Council passed a resolution on the establishment of the Győr-Sopron County Bakery Company, and at the same time, with effect from January 1, 1953, it abolished the name of the Győr Bread Factory Company as a state-owned company.

Personnel issues were also decided in connection with the reorganization: “…the reorganization will not result in any significant personnel changes, we intend to leave everyone in place.”

It was stated at the meeting that the company is struggling with serious technical difficulties, they are unable to meet the sudden demand of trade only if technological instructions are not followed, meaning that this is the only way they can increase capacity.

A suggestion was also made that the uneven demand could be met by storing pre-baked bread in the cold store. The cold store had to cope with the proper cooling of the meat products, so it did not have the capacity to store additional products.

The establishment of the Győr and Region Bakery Company – 1953

(Ceres Sütő Zrt. considers 1953 to be the year of its founding, and in 2023 they celebrated the 70th anniversary of the factory's existence)

The Ministry of Food Industry founded the Győr and Region Bakery Company from the Győr-Sopron County Bakery Company on October 21, 1953, under document number 207403/1953.

Although the company was placed under county control, this did not help solve the infrastructural problems. A contemporary article vividly describes the conditions prevailing in the city's bakeries in 1954, as there was no mention of a modern bread factory.

Géza Csizmadia: A Bread Factory for Győr. Győr-Sopron County Newspaper, June 6, 1956. No. 132. p. 3.

Source: https://adt.arcanum.com/hu/

There were 28 smaller and larger nationalized bakeries operating in the city, eleven of which were closed down due to inadequate operation. Despite all the difficulties, the workers in the Győr plants of the Győr-Sopron County Bakery Company performed well.

Kisalföld, 1958. Nov. 7. No. 263. p. 7.

Source: https://adt.arcanum.com/hu/

The construction of the bread factory in the city of Győr, which had a population of 80,000, was not included in the first (1950–1954) and second five-year plan, which was actually changed to the second three-year plan (1958–1960). The bread factory was finally built in the second five-year plan period (1961–1965).

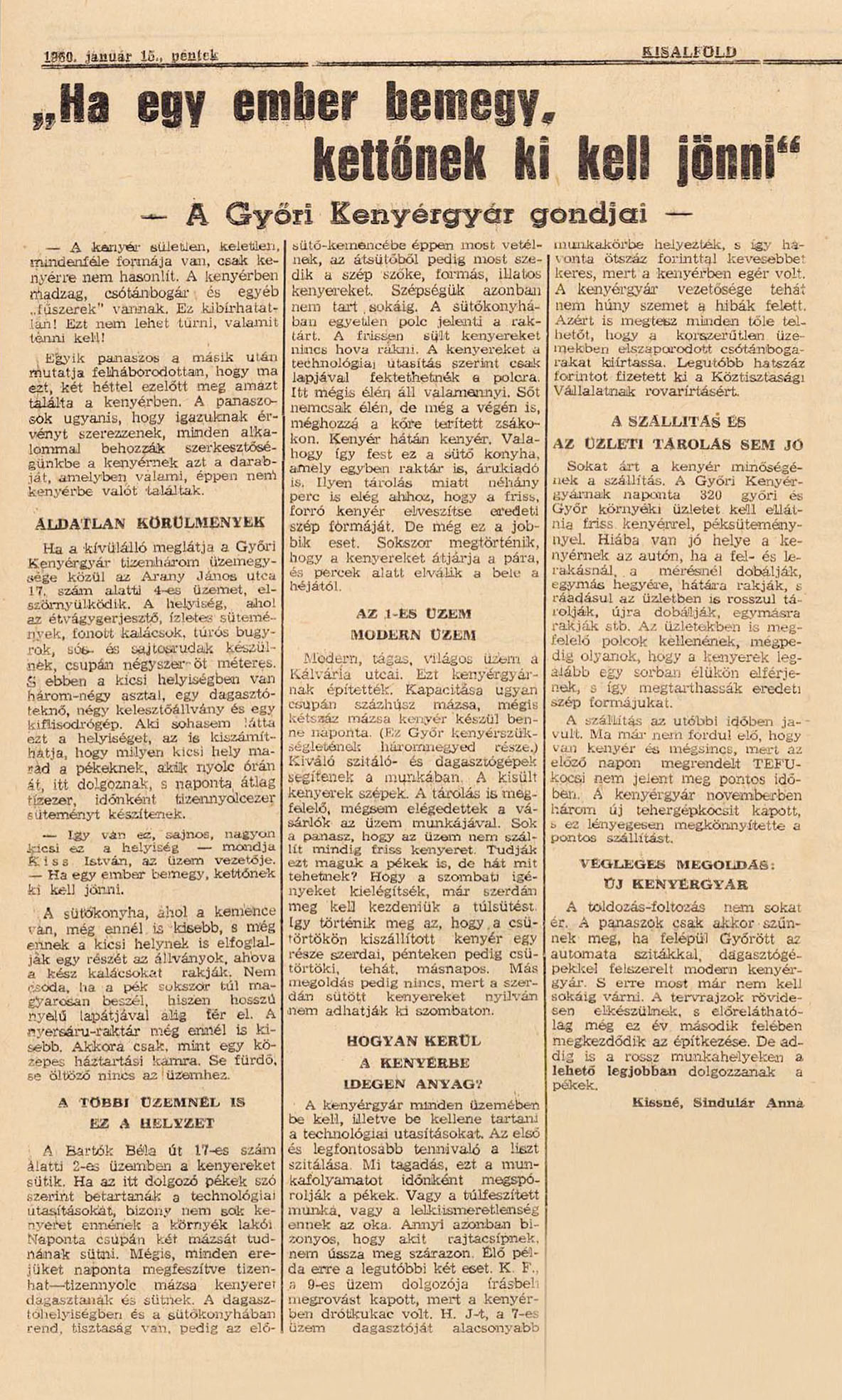

Articles about bread production appeared in the press from time to time. Győr's supply difficulties and quality complaints were constant at that time. Anna Kissné Sindulár, a journalist from Kisalföld, writes in detail about the conditions prevailing in some of the company's factories in her report published with the telling title "If one person goes in, two have to come out".

Anna Kissné Sindulár: "If one person goes in, two have to come out. The troubles of the Győr Bread Factory. Kisalföld, 15 Jan. 1960. No. 12. p. 5.

Source: https://adt.arcanum.com/hu/

A bread factory is being built

By the 1960s, it became obvious that the existing production capacities could not supply the population of the city and its surrounding area with quality baked goods.

Based on the plans of the ÉM Győri Tervező Vállalat (Győriterv), several bread factories were built in the country, the construction of the most mechanized and highest-performing of them began in Győr, in the vicinity of the cold store and the Industrial Canal, under the construction of the Győr County Construction Company. In the city's long-term development plan, this area was intended to be declared an industrial quarter. The design documentation was completed by the beginning of 1961, and the actual start of the works was scheduled for June of that year, i.e. it was implemented during the period of the second five-year plan (1961–1965).

Kisalföld regularly reported on the start of construction and the modern production equipment of the new factory.

The Győr Bread Factory under a roof. Kisalföld, 1962. Aug. 19. No. 194. p. 3.

Source: https://adt.arcanum.com/hu/

According to the plans, the factory, including the production line, the mailroom, offices, changing rooms, and restrooms, was to be completed by July 31, 1963.

Despite all prior announcements and plans, the factory was not completed by the specified time. The Construction Company requested a change in plan citing bad weather, but this did not affect the commissioning of the factory, according to them. On the other hand, the dismantling and excavation of the wall sections serving as the location of the machines and equipment could not be completed, and because of this, the Budapest Mill Assembly and Machine Manufacturing Company was unable to install the power transmission equipment.

The production of the new factory was planned for a fifty-year period in 1958, during the investment program, when the city's need was 2-2.4 wagons of bread. According to the plans, the factory would bake 3 wagons of bread in two shifts, and in three-shift operation it would be able to bake 4 wagons (400 tons) of bread. Even if the population's consumption doubled, they would still be able to supply the city with enough bread. At this time, it was decided in Győr that the city wanted to establish a university. It became questionable whether the bread factory would be able to satisfy the thus increasing consumption. The concerns proved to be unfounded, and the issue of establishing a university was dropped from the agenda.

Under the county authority of the Győr-Sopron County Council VB.

Győr and its Region Bakery Company

During the construction of the Győr bread factory, the companies were "incorporated", so by the time the factory started operating, it was already maintained by the county.

There was a lot of uncertainty and unclear issues surrounding the county-levelization of companies, both among the city and county leadership. Győr-Sopron County was the last to bring the bakery industry and the waterworks under its direct control.

The county's bread supply was essentially provided by 5 baking companies in Győr, Sopron, Mosonmagyaróvár, Csorna and Kapuvár, apart from an insignificant number of private artisans engaged in supplementary activities. They were managed by the industrial and technical department of the city council of their seat, despite the fact that their supply area did not extend only to the given city.

At its meeting on November 9, 1962, the Győr-Sopron County Council merged the Csorna company with the Győr company, and the Kapuvár company with the Sopron company.

From 1963, the new names of the companies were:

– Győr-Sopron County Council VB. Győr and its Region Bakery Company,

– Győr-Sopron County Council VB. Sopron and its Region Bakery Company,

– Győr-Sopron County Council VB. Mosonmagyaróvár and its Region Bakery Company

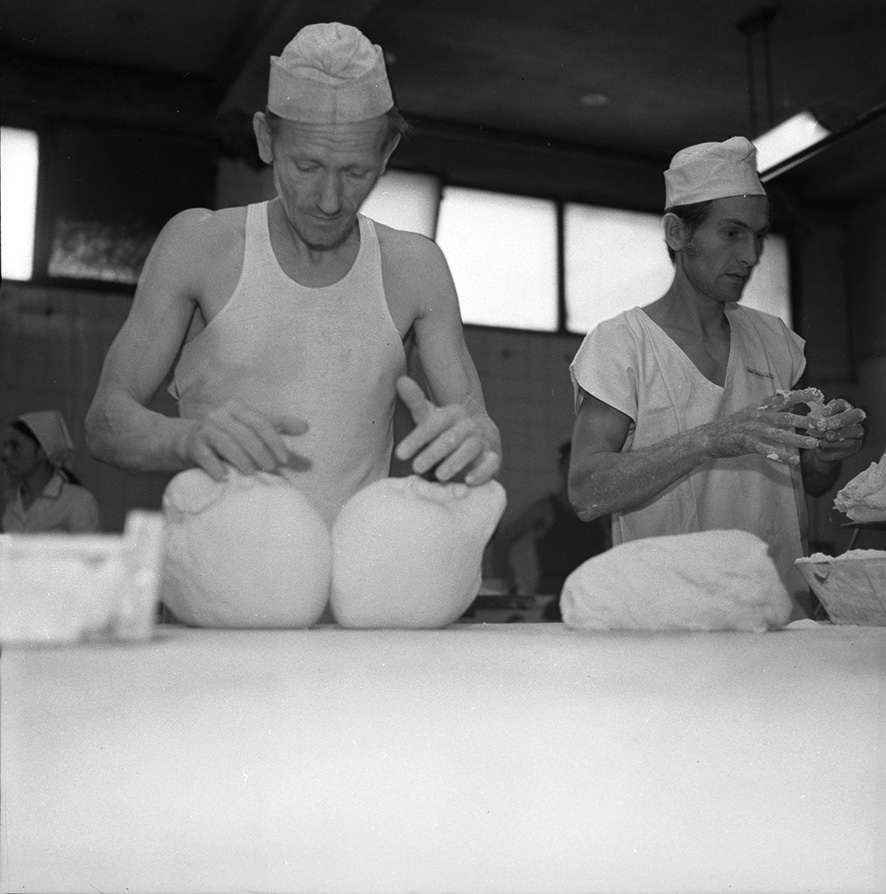

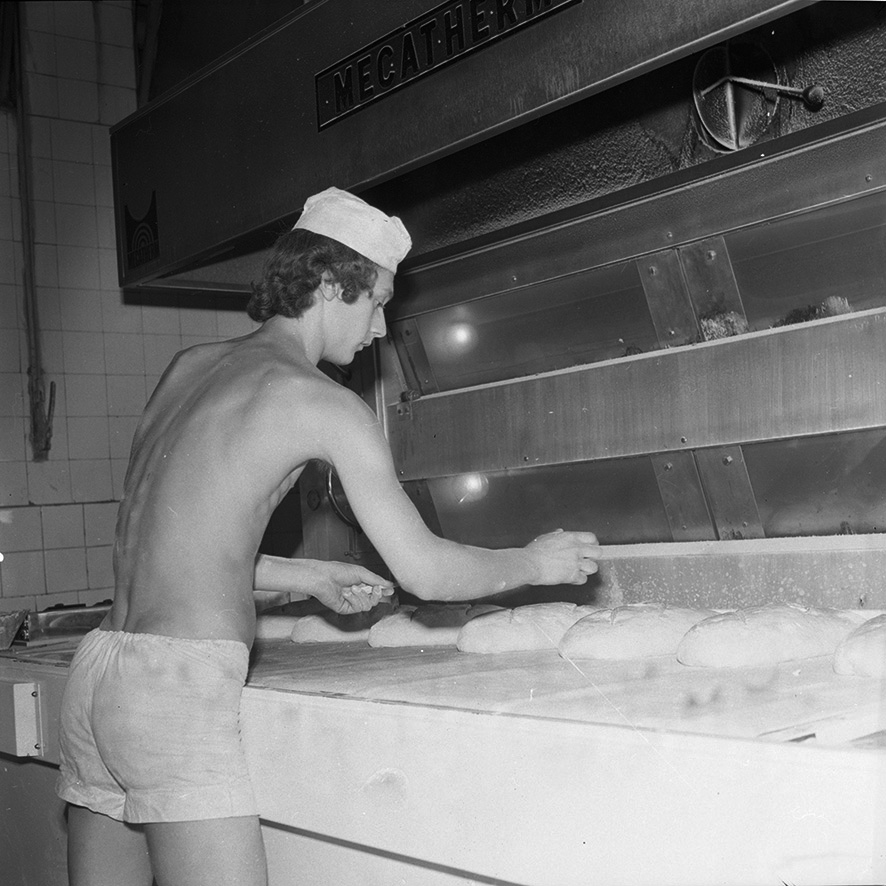

The bread factory produces

After some delay, on May 30, 1964, the test baking finally took place, which marked the start of production in the bread factory.

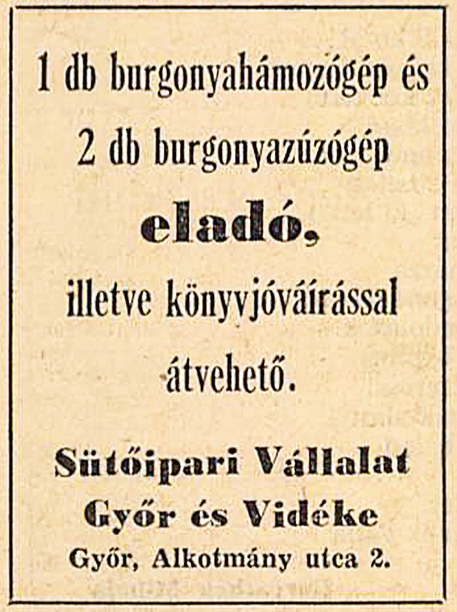

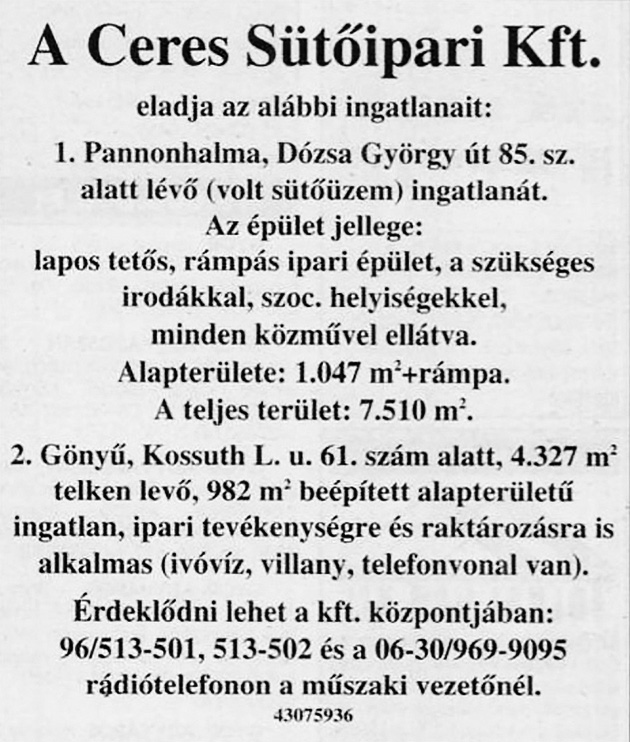

The company advertised the obsolete, unnecessary equipment for sale in the press.

Advertisement. Figyelő, 1963. Jun. 19. No. 25. p. 11.

Source: https://adt.arcanum.com/hu/

József Schaub, the company's director, has spoken several times about the reasons for the prolonged trial operation, the issues related to the quality of the bread and the delivery problems in the columns of the county daily. The technical problems that arose were primarily caused by the difficulties in commissioning the equipment installed as a prototype in Győr, since the technology was tested here by the experts. The procurement of raw materials - including the constantly changing quality of flour - also influenced the development of the exact technology.

Thanks to the rapid kneading, the fifteen-minute process was shortened to seconds. The dough produced in this way reached the feeder of the chamber dividing machine located one floor below through a sliding hatch, and then to the forming machines. The manufacturer of the experimental equipment patented by the Baking Industry Research Institute was ÉLGÉP, an internationally renowned large company in the industry. The research institute carried out the professional development and commissioning in close cooperation with the factory's laboratory.

The new factory also faced a logistical challenge: the delivery time was shorter than the factories operating in the city, but the new factory was built further away from the shops. The factory, which was eventually built with an investment of 30 million, was not provided with modern bread delivery trucks.

From the mid-1960s, there was an increasing demand for white goods, so it seemed justified to increase production capacity. The new plant was established by the company with its own resources, with an investment of two million forints, on the site of the bread factory, in the former bread warehouse. The plant, which was opened in 1968, baked 90,000 pastries per shift in modern oil-fired ovens, and flour storage was also modernized. A flour silo with a capacity of 120 tons was also set up on the factory premises.

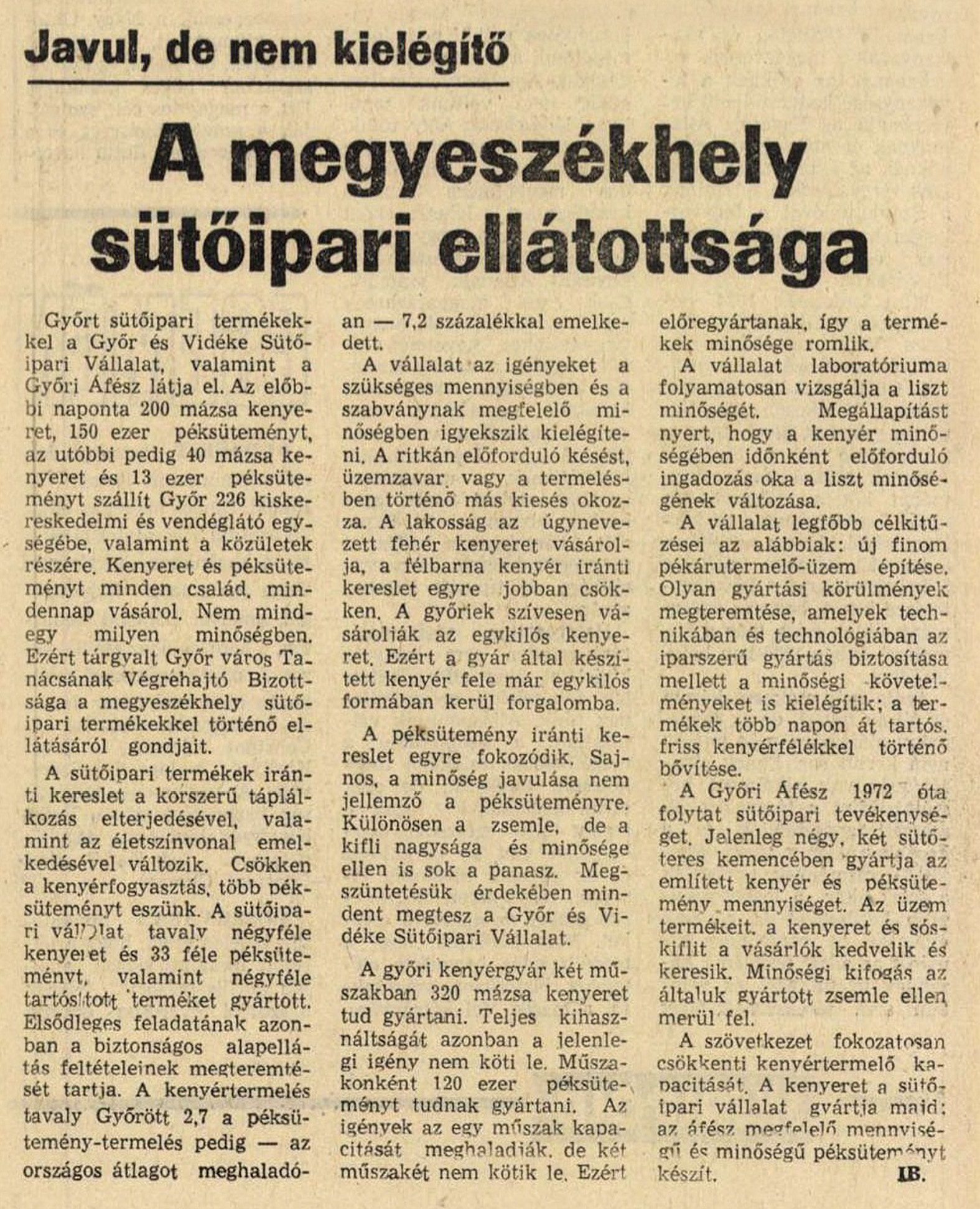

In the early 1970s, Győri Áfész established its own bakery in Győr next to the former Fehérvár customs. The first bakery with a significant production capacity created a new market situation. In 1978, the city was supplied by the Győr és Vidéke Sütőipari Vállalat and Győri Áfész, delivering 200 mazzas of bread and 150 thousand pastries daily, as well as 40 mazzas of bread and 13 thousand pastries to 226 retail and catering units, as well as to public institutions.

In March 1977, the company's director Pál Szalami told Kisalföld:

Bread is a state-subsidized product, and there is no profit in its production. Renovations are possible only if the company receives state support. In the IV. five-year plan period, 25 million forints were spent on development.

“The production of bakery equipment does not have a long tradition in our country, or even in socialist countries. Most of the new equipment was prototypes, which necessarily had to be modernized during bread production. The renovation was ultimately successful. The bread factory proved that good bread can be baked using large-scale methods.”

"The domestic baking industry has only reached a large-scale level worthy of the word industry in just a few years, and the entire sector still has plenty to develop."

Béla Imre: The bakery industry supply of the county seat. It is improving, but not satisfactory.

Kisalföld, 1978. Apr. 8. No. 82. p. 1.

Source: https://adt.arcanum.com/hu/

Sample shops

The company operated several sample stores from the very beginning. Of course, the latest products could be bought here, so it is no wonder that customers lined up in front of these stores. In Győr, there were initially sample stores on Baross út, Kossuth, Arany János and Kálvária utca, but these popular products could also be found next to the Győr bread factory and the factories in the countryside. The novelty “snack bar” (hot-dog croissant) and hamburger buns were very popular. The entrepreneurs obtained these hit products directly from the sample store on Kálvária utca.

The contemporary advertisement lists specialty stores and presents the latest products.

Kisalföld, 1992. Aug. 19. No. 196. p. 8.

Source: https://adt.arcanum.com/hu/

Privatization of the company

Already on October 28, 1992 – as a preparation for privatization – a significant change took place: the company's management form changed from "managed by the assembly of delegates" to "under state administrative supervision".

The title of an article published in the local newspaper in August 1993 reveals a lot about the tasks facing the company:

The two-kilo bread is barely sold anymore. The Győr “bread factory” before transformation.

The former monopoly of the bakery company is now a thing of the past. In addition to the exclusive large-scale production, smaller bakeries have reappeared, and the supply market has become saturated. Despite all this, the company still has a market share of about 40% in the county seat and its surroundings in 1993. Nearly 400 employees produce 200 tons of bread and 200 thousand pieces of pastries every day, in the five remaining production plants after the forced closure of the Tet bakery. The company will close the year with a profit despite the fact that they offer their products to commercial companies at a discount.

The article also reports that a plan to transform into a joint-stock company has been completed.

This plan became a reality that same year, and the Győr and Region Bakery Company was transformed into a joint-stock company on December 31, 1993. The owner is the ÁVÜ (State Property Agency).

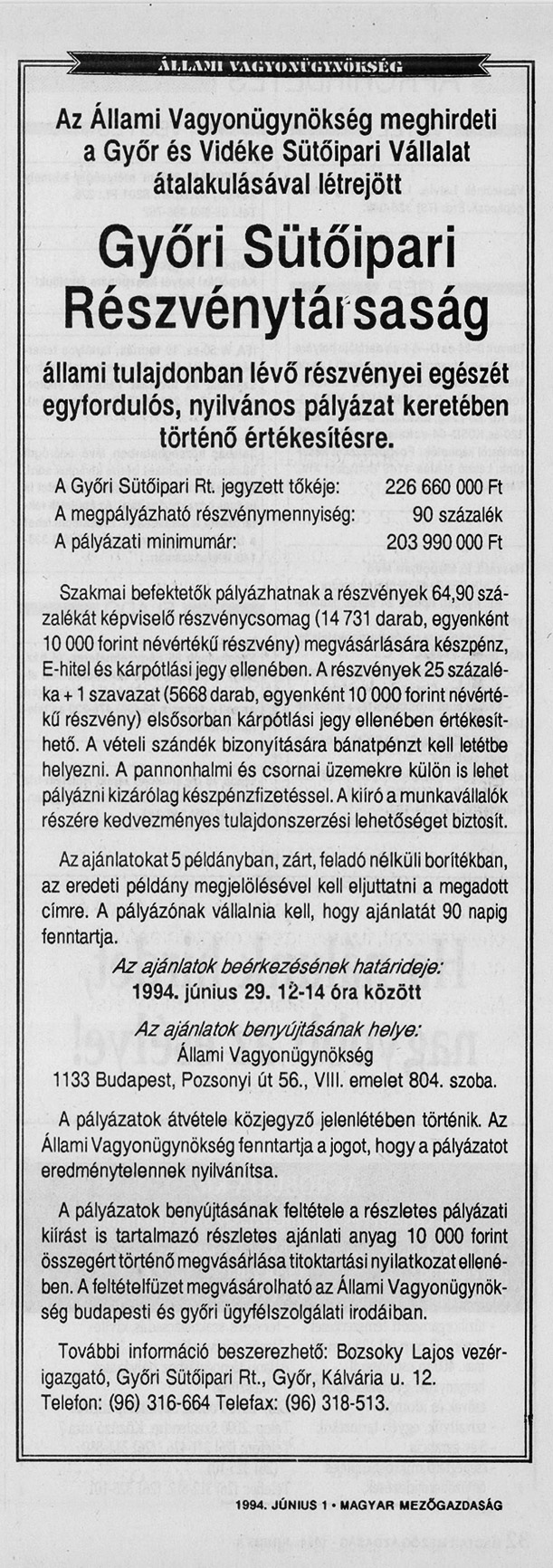

The entire state-owned shares of Győri Sütőipari Rt. were floated on the market in June 1994. Magyar Mezőgazdaság, 1 June 1994, No. 22, p. 31.

Source: https://adt.arcanum.com/hu/

The joint-stock company began operations on January 1, 1994. At that time, the company's net sales revenue was 512 million forints, its subscribed capital was 226.660 million forints, of which 10% were employee shares. The remaining 90% of the share package was advertised for sale.

The company had 387 employees.

Győri Sütőipari Rt. was privatized in 1994 by Csopak Szövetkezeti Rt., which represented four companies. Seven applications were received for the tender for privatization, and the winning company, Csopak Szövetkezeti Rt., made an offer at a rate of 151 percent. The purchase price was paid in cash and partly in compensation notes.

The change of ownership took place on November 4, 1994. 90% of the shares were purchased by four companies.

The shareholders:

– Csopak Cooperative Limited Liability Company (Nemesvámos) – as the main shareholder

– Balatonfüred-Csopak Landscape Cooperative (Nemesvámos)

– Herendvidéke Agricultural Cooperative (Márkó)

– Balatonfő Agricultural Producers' Cooperative (Balatonfőkajár)

Ancillary industries

In addition to bakery products, the factory also produced breadcrumbs from the very beginning, which it sold in ¼ and ½ kg packages, in accordance with the practice of the time.

In order to expand the market, a dry pasta factory was established on the site of the bakery canteen. The company received the manufacturing license in June 1994. Two types of products were produced, 6-egg vermicelli and 6-egg wide pasta.

Multi Pékség Bt. was founded by Multi-Land Kft., a subsidiary of Csopak Szövetkezeti Rt., on December 15, 1992, together with the Petz Aladár County Hospital in Győr, in order to serve the hospital's special bread and pastry needs. Petz Aladár County Hospital owned 43.8% of the shares. The plant was established by renovating a building in the Vasvári Pál Street barracks, where high-quality hygienic conditions were provided, creating conditions for product production, as a result of which the company could become a supplier to schools, kindergartens, and the hospital.

The subsidiary merged into Ceres Zrt. on June 5, 2012.

The new name of the company: Győr Bakery Limited Liability Company

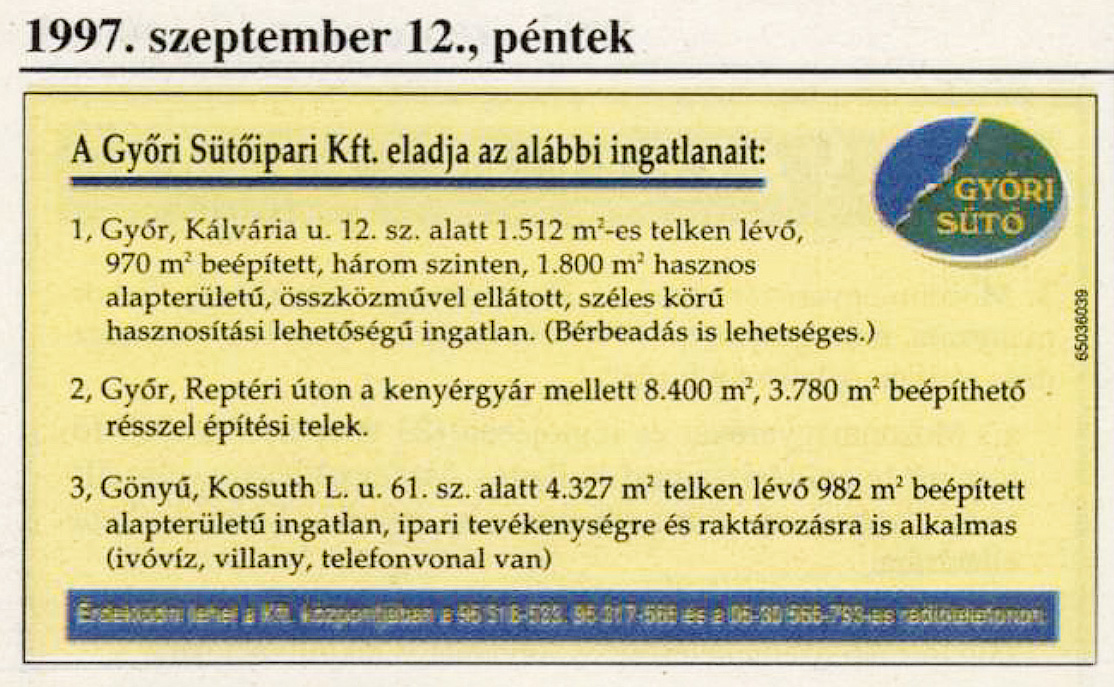

As a prelude to the change of name and corporate form, Csopak Rt. purchased the shares from the cooperatives, thus becoming the sole owner, excluding the employee shares. From January 1, 1997, the company changed to a simpler corporate form in accordance with the expectations of the owners, and continued its activities as a limited liability company under the name Győri Sütőipari Korlátolt Felełősségű Társaság.

This year, the vehicle fleet was replaced, and 12 Mazda trucks were purchased for 41 million forints.

The brand new white fleet of vehicles, with the company logo on them, was impressive in appearance. This also meant a kind of national advertising space, which was still a novelty at the time. These cars traveled the country, displaying the company logo everywhere. Coming from Miskolc and Budapest towards Győr, it happened that 3-4 company Mazdas could be seen on the highway in the afternoon.

The modernization of the transport fleet continued in the following years, and in 1998 Győr received 2 more Renault trucks, worth a total of 8 million forints.

The company reduced the number of its properties in the spirit of rationalization. In the interest of increasing efficiency and economy, it continuously consolidated its entire production into the Győr bread factory from 1996, and sold the properties thus freed up.

In 1998, the company installed new outdoor silos and a Spiromatic automatic flour system instead of the previous concrete silos. The previous bagged flour collection was replaced by a modern, computer-controlled system, which delivered the flour to the kneading site in quantities determined by the recipes. In addition to the more accurate flour dosing and significant cost savings, it also replaced the bagged movement of the most used raw material, flour, between floors.

With the nationwide delivery, the demand for packaged products increased. Therefore, the company began the technical development of packaging. One of the first steps was the purchase of a FALCON packaging machine in 1998.

On September 30, 1999, Győri Sütőipari Kft., together with the main owner Csopak Szövetkezeti Részvénytársaság, purchased the Miskolc-based Miskolc Sütőipari Korlátolt Felelfösségű Társaság. The company now had production sites in two different parts of the country. The Miskolc site still plays a significant role in the national supply chain. Győri Sütőipari Kft. owns 49% of the shares, Csopak Szövetkezeti Rt. owns 51% of the shares, but due to the same industry, it is under the operational control of Győri Sütőipari Kft.

New name: Ceres Bakery Ltd.

When the subsidiary Miskolci Sütőipari Kft., which had a similar professional history, merged with Győri Sütőipari Kft. on September 30, 2002, the company changed its name because it did not want to appear with the regional name of Győri in other parts of the country. Therefore, it looked for a name free of geographical designations.

To choose the new name, the company announced a competition, which was conducted jointly with the then Marketing Department of Széchenyi István University in Győr and was also advertised among students. Among the competitions, the name Ceres, the name of one of the goddesses of Roman mythology, was received as a student suggestion.

The original bearer of the name Ceres was the goddess of fertility, grain planting, harvest, agriculture, and maternal love. According to mythology, Ceres (Greek name Demeter) introduced humanity to the mysteries of grain cultivation, so we can actually thank the goddess Ceres for the creation of bread.

This name was liked by everyone involved, so during the 2002 merger, at the same time, it adopted the new name, which it has since developed into a brand name.

A new bread factory is being built in Győr

National freight transport and modern trade required products that, unlike previously common fresh products, would remain fresh for several days, providing great convenience to both consumers and retailers. The new types of toast breads, already known in Western Europe, were also sought after by domestic consumers, as there was an increasing demand for healthy and higher value-added products.

Ceres Sütőipari Kft. began construction of a new bread factory in 2000. The company's first Dutch toast line was located in a facility built with a "greenfield" investment of nearly 1 billion forints on the site, in the free space available in front of the existing building.

According to the information provided by Dr. Tormáné Kása Margit, the development involved the use of 434 million forints of own funds and 831 million forints of loans. The plant was equipped with the most modern German technology, and its capacity increased the performance of the Győr plant by 120 percent. The 2,600 m2 plant hall, which was named Plant No. 2, was the first in the country to install an automatic toast bread production line, which was supplied and installed by the globally recognized bakery machinery manufacturer, the Dutch KAAK Group. The commissioning of the highly efficient automatic production line also significantly helped solve the labor problem that has been ongoing in the bakery industry for years.

Initially, white and semi-brown breads were produced on the production line. Later, thanks to continuous product developments aimed at satisfying customer needs, seed-enriched, low-carb breads were also introduced.

At the same time as the multi-year program of replacing the machine lines, production was also centralized. This meant the sale of the two remaining rural sites in 2005, thus merging all production activities into the Győr bread factory.

Ceres Bakery Private Limited Company

On December 28, 2004, Csopak Rt. sold its shares to Ivydale Investments Ltd. (96.8%) and Inverdale Investments Ltd. (1.0%), registered in Cyprus. With this, the company became directly owned by the shareholders of the entire Csopak group of companies, without the intervention of Csopak Rt. In essence, this was a technical change of ownership, with which Ceres Sütőipari Kft. became a direct member of an international group of companies.

On November 30, 2005, Ceres Sütőipari Kft. was transformed into a joint-stock company. Its name became Ceres Sütőipari Zártkoruen Mőködő Rezvénytársaság.

The new owner

On June 17, 2010, the entire share package of the company was acquired by a professional investor, Penam as (Czech Republic). This marked the end of an era and the beginning of a new era in the life of the company.

Penam, a leading manufacturer of bakery and milling products in the Czech Republic, was established in 1999 by merging 12 Czech milling and bakery companies. Through Penam as, the company became a member of the Czech-based AGROFERT as group of companies.

The purchase and sale negotiations took place at the beginning of 2010, so the development and adoption of products already existing and manufactured on the Czech market to the Győr site could begin.

Following the change of ownership, Ceres started its export activities to the new parent company in June. The volume of products manufactured for Penam as reached 3,312 tons in 2010.

The reason for the significant export shipments was Penam's limited production capacity. Although they also produced toast bread, they were unable to independently satisfy the needs of their own domestic market.

Since 2011, the export volume has been increasing continuously, and by 2013 it had almost tripled, reaching an annual volume of 9,324 tons.

The transition affected all processes, from the operation of the raw material supply system, to the review of other production procedures, to the unification of quality assurance rules. Ceres was re-aligned to the model of Penam's operational structure, taking into account the specificities of Hungarian production.

The end of 2019 and the year 2020 were of decisive importance not only in the life of Ceres, but also in the history of humanity, as a global pandemic began, which had never been experienced before. For the company, the primary task in 2020-21 was to adapt to the new circumstances. The factory had to produce and market bread, as a staple food, in the most hygienic and practical packaging possible under the new and constantly changing circumstances.

From the second half of 2021 and into 2022, the new production regime has become normalized and routine, but consumer and purchasing habits have changed permanently. The increased customer demand for packaged products has remained in the long term. As a result of this, a favorable trend for Ceres, the production and sales volume has increased, and the utilization of production capacity has been around 85%.

Names:

Győr Bread Factory September 15, 1950.-

Győr-Sopron County Bakery Company January 1, 1953.-

Győr and its Region Bakery Company October 21, 1953 -

Győr-Sopron County Council VB. Győr and its Region Bakery Company January 1, 1963.-

Győr Bakery Co., Ltd. January 1, 1994.-

Győri Bakery Ltd. January 1, 1997.-

Ceres Bakery Ltd. September 30, 2002.-

Ceres Bakery Ltd. November 30, 2005.-

| INTERESTING FACTS |

|

The first loaves of bread |

||

|

It is believed that baking bread was invented by accident when a thick mixture of ground grain and water fell onto a hot stone. It is also a coincidence that leavened bread was invented when barley dough stored in clay pots swelled, became bubbly, and baked into a lighter, more delicate loaf. We find records of bread in Mesopotamian, Assyrian, Egyptian, Greek, and Roman writings, which were already very diverse: from unleavened flatbreads baked on hot stones to leavened bread used in Egypt 3,000 years ago. Bakers were already working in Greek civilization, in Roman culture bread was baked at home by servants, but archaeologists have also found bakeries during excavations. The Romans, known for their luxurious feasts, could not imagine their lives without bread, yet it took centuries for a different, new type of bread to be created from flatbread by fermenting the dough. Many small discoveries led to the countless bread baking methods and recipes that exist today, and the science of oven construction also developed in parallel. The Hungarians who conquered the country were also familiar with bread, and in their ancestral homeland they grew grain for food around their winter quarters. It is interesting that in the Hungarian language, kenyőr only means high, fermented bread, although it is probably a loanword from the Old Hungarian period, and its early meaning, based on related linguistic data, could have been “a type of porridge, a type of food made from semolina.” At the time of the conquest, the word kenyőr presumably meant only flatbread, although linguistic data on this only survives in a church text from 1315. Grain production in our country began to grow significantly in the 16th century. According to studies, from this time on, Hungarian peasant households used 130–160 kg of bread grain per capita for their own consumption. In the early modern era, bread was eaten at main meals, with cooked, hot dishes, and as a base for complementary meals with bacon, meat, and dairy products. This has led to the tradition of serving bread with hot dishes, whether soup, vegetables, or other non-carbohydrate-based dishes. |

|

New factory, new technology |

||

|

In Hungary, a new and unknown technology was put into operation in the Győr bread factory, which - due to the lack of previous experience - imposed countless adjustment and fine-tuning tasks on the designer and the factory's specialists. At the start, dough production was still done with traditional rotary-arm kneading machines. Bread dough division was done with piston dividers, rounding was done with belt rounding machines, and longitudinal shaping was done with belt longitudinal shaping machines. After baking, the finished product went down a chute to the ground-floor warehouse (which often got stuck), where the hot bread and pastries were picked up and placed in the characteristic aluminum crates with bare hands, without gloves. The real innovation was the cradle proofer installed in the system and the East German-made BN 50 tunnel ovens. The proofing took place almost without human intervention. From the length former, the dough was placed in the proofer, which, after proofing, was automatically transferred to the seeding cloth and then to the oven. The equipment did not live up to expectations. It was later replaced and the classic leavening process was returned to. The operation of the BN 50 tunnel kilns was also not smooth. They wore out quickly due to soot deposits, and their steam retention was not adequate. Since only the same type could be installed in their place, a satisfactory solution had to be found on site. The company's specialists successfully solved the problem of steam retention by installing steam retention zones. After that, the installation of the BN 50 kilns was supported nationwide. |

| LITERATURE |

József Kurucz: The History of the Győr Industrial Association and the Old Győr Industrial Associations. Printed by Pannónia Printing House, Győr, 1911. Page 37 (further pages).

City Bread Factory. City Newspaper, 1912. Feb. 3. No. 5 (hereinafter referred to as No.) pp. 33-36.

Győr. City Newspaper, 1914. Jan. 3. No. 1. p. 8.

Bread factory in Győr. Városok Lapja, 1914. Mar. 7. No. 10. p. 120.

Győr. Establishment of a bread factory. Entrepreneurs' Newspaper, 1916. Apr. 26. No. 17. p. 9.

They intend to build a bakery in Győr. Városok Lapja, 1 April 1923 , No. 7, p. 52.

Starting Sunday, bread rolls and other pastries will be cheaper….Győrmegyei Hírlap, 1949. Dec. 3. No. 281. p. 3.

7 catering companies, 15 meat factories, 8 bakery village companies for the workers of Győr. Győrmegyei Hírlap, 1949. Dec. 4. No. 282. p. 11.

Archives of the City of Győr with County Rights. (Later: GyMJVL). XXIII. 102/1. Minutes of the Executive Committee of the City Council of Győr. Resolution of issues related to bread supply. 1950/5. no. (1950.09.08.)

Archives of the City of Győr with County Rights. GyMJVL. XXIII. 102/1. Minutes of the Executive Committee of the City Council of Győr. 5/c. Foundation of the Győr Bread Factory. 1950/6. no. (1950.09.15.)

Archives of the City of Győr with County Rights. GyMJVL. XXIII. 102/1. Minutes of the Executive Committee of the City Council of Győr. 2nd supplementary agenda: Proposal for improving the bread supply of the city of Győr. 1952/37. no. (1952.08.29.)

Archives of the City of Győr with County Rights. GyMJVL. XXIII. 102/1. Minutes of the Executive Committee of the City Council of Győr. Announcements: 4/ Development of the Győr Bread Factory with a new production section. 1952/46. no. (1952.10.31.)

Hungarian National Archives Győr-Moson-Sopron County Győr Archives. (Later: MNL GyMSVGyL). Minutes of the Executive Committee of the Győr-Sopron County Council. 6. Matters requiring approval. 1.) Establishment of the Győr-Sopron County Bakery Company. 51/1952. (1952. 12. 17.)

Following letters from the Győr Bakery Company. Győr-Sopron County Newspaper, 1954. Jan. 16. No. 13. without page number (hereinafter referred to as on)

Géza Csizmadia: A Bread Factory for Győr. Győr-Sopron County Newspaper, June 6, 1956. No. 132. p. 3.

Kisalföld, 1958. Nov. 7. No. 263. p. 7.

Kissné Anna Sindulár: "If one person goes in, two have to come out. The troubles of the Győr Bread Factory. Kisalföld,

1960. Jan. 15. No. 12. p. 5.

The Győr Bread Factory is being built. Kisalföld, 1961. Sept. 9. No. 213. p. 1.

The Győr Bread Factory under a roof. Kisalföld, 1962. Aug. 19. No. 194. p. 3.

Hungarian National Archives Győr-Moson-Sopron County Győr Archives. MNL GyMSVGyL. Minutes of the Executive Committee of the Győr-Sopron County Council. 2. The situation of bakery companies and their placement under direct county control. 22./1962. (1962.11.09.)

The county council's executive committee discussed the county's bread supply. Kisalföld, 1962. Nov. 10. No. 263. p. 3.

János Kristóf: When does the Győr Bread Factory bake bread? Kisalföld, 1963. June 7. No. 131. p. 3.

They are generalizing the bread factory. Kisalföld, 1968. Feb. 10. No. 34. p. 1.

KL: A croissant, bun, cake factory... doesn't fit in my pocket. Kisalföld, 1969. Jul. 11. No. 158. p. 1.

Béla Imre: World Cup meeting in the bread factory. The quantity of bread is sufficient, the quality is objectionable. Kisalföld, 1970. Sept. 26. No. 226. pp. 1-2.

Béla Imre: A small bread factory is being built in Győr, a large department store is being built in Győr-Szentiván. Kisalföld, 1971. May 22. No. 119. pp. 1-2.

IB: The bakery industry supply of the county seat. It is improving, but not satisfactory. Kisalföld, 1978. Apr. 8. No. 82. p. 1.

Péter Lőre: The two-kilo bread is barely sold anymore. The Győr “bread factory” before transformation. Kisalföld, 1993. Aug. 18.193. No. 13. p.

Győr and its Region Bakery Company may be transformed into a joint-stock company. ÁVÜ-hírek. Magyar Mezőgazdaság, 1993. Dec. 8. No. 49. p. 3.

Announcement of the state-owned shares of Győri Sütőipari Rt. Magyar Mezőgazdaság, 1 June 1994, No. 22, p. 31.

József Ferenczi: Bread is their bread. Kisalföld, 1994. Oct. 5. No. 233. p. 3.

In competition with multinationals, Csopak Rt. Világgazdaság, 1996. Oct. 29. No. 209. p. 13.

RZ: Small next to the big. Kisalföld, 1999. Jan. 26. No. 21. p. 11.

Developed by Csopak. Diary, 2001. Apr. 18. No. 90. p. 6.

Csopak became closed-ended. Napi Gazdaság, 20 Feb. 2002, No. 36, p. 12.

József Ferenczi: Integral rt.: keeping the standard. Kisalföld, 2003. May. 26. 121.sz. 13. p.

New bread factory in Győr. Ceres modernizes its plants. Világgazdaság, 2003. Aug. 5. No. 151. p. 7.

Lehöcz Rudolf: Ceres Ltd. is in full swing. Világgazdaság, 2004. Sept. 21. No. 183. p. 15.

Minibaguette, emperor's roll and ciabatta. Magyar Hírlap, 2005. Jun. 8. No. 132. p. 25.

László Avar: Ceres: even better! Hungarian Agriculture, 2007. Dec. 12. No. 50. pp. 30-31.

Concentration awaits the baking industry. Napi Gazdaság, 2008. Feb. 25. No. 39. pp. 1-2.

Strength in unity. Figyelő, 2008. Oct. 9. No. 41. p. 45.

Szirmai S. Péter: Csúcsvacakok. More and more domestic food industry companies are trying to compete in price by consciously reducing quality. Figyelő, 2010. March 4. No. 9. 50-51. on

Ceres in Czech hands. Figyelő, 2010. Mar. 11. No. 10. p. 8.

Ceres Zrt. written documentation and oral communication

Ceres Zrt. website: https://ceressuto.hu/ (Downloaded: 8 Sept. 2023)

Back to the previous page!